Machining device for sheet cathode electrolyte direct injection machining large-lead nut and machining method of device

A catholyte and processing device technology, applied in the direction of electric processing equipment, electrochemical processing equipment, accessory devices, etc., can solve problems such as difficult to wash away electrolytic products, affect processing speed and stability, and large loss of kinetic energy of electrolyte, etc. Achieve the effects of stable and reliable processing efficiency, wide processing range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

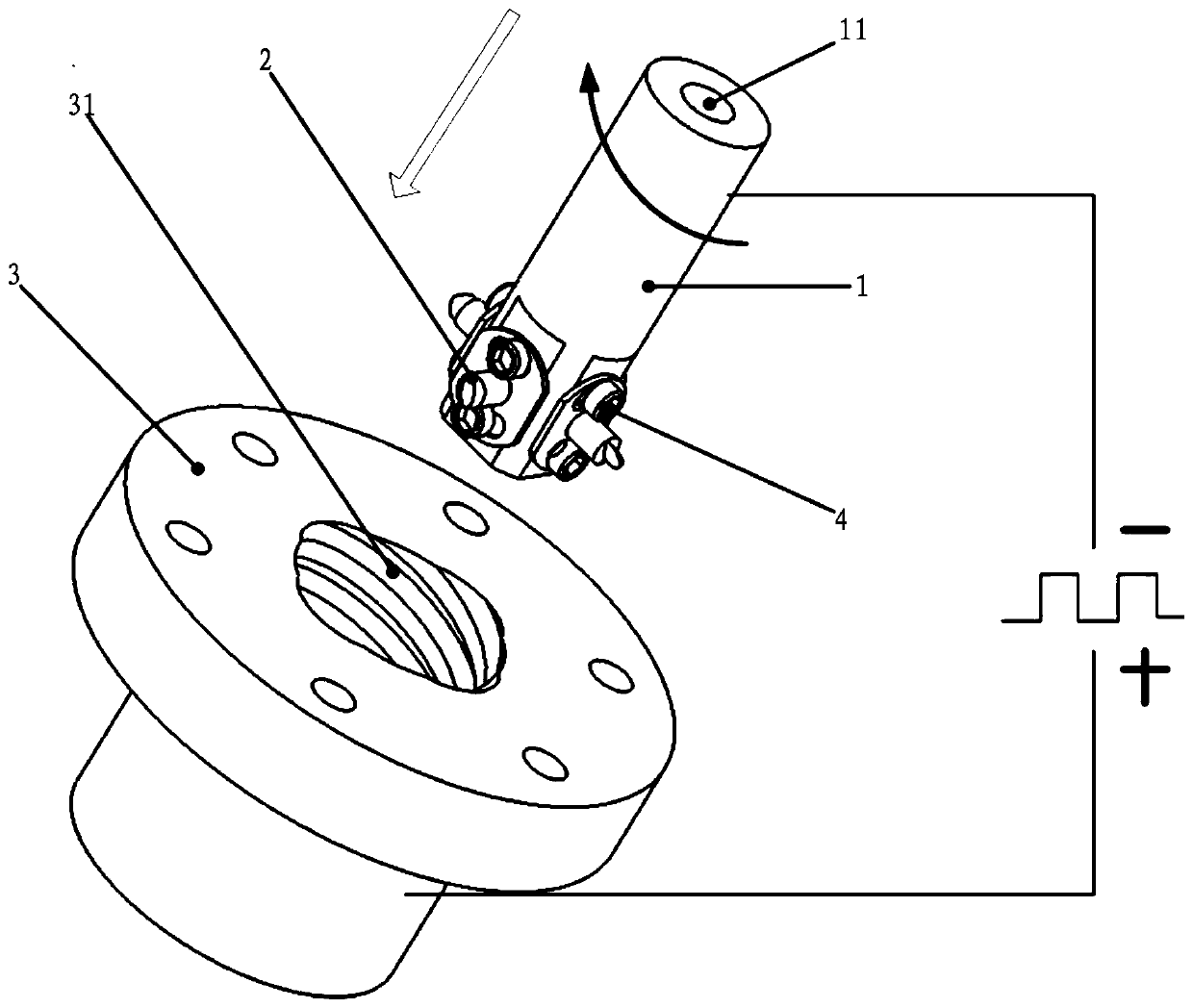

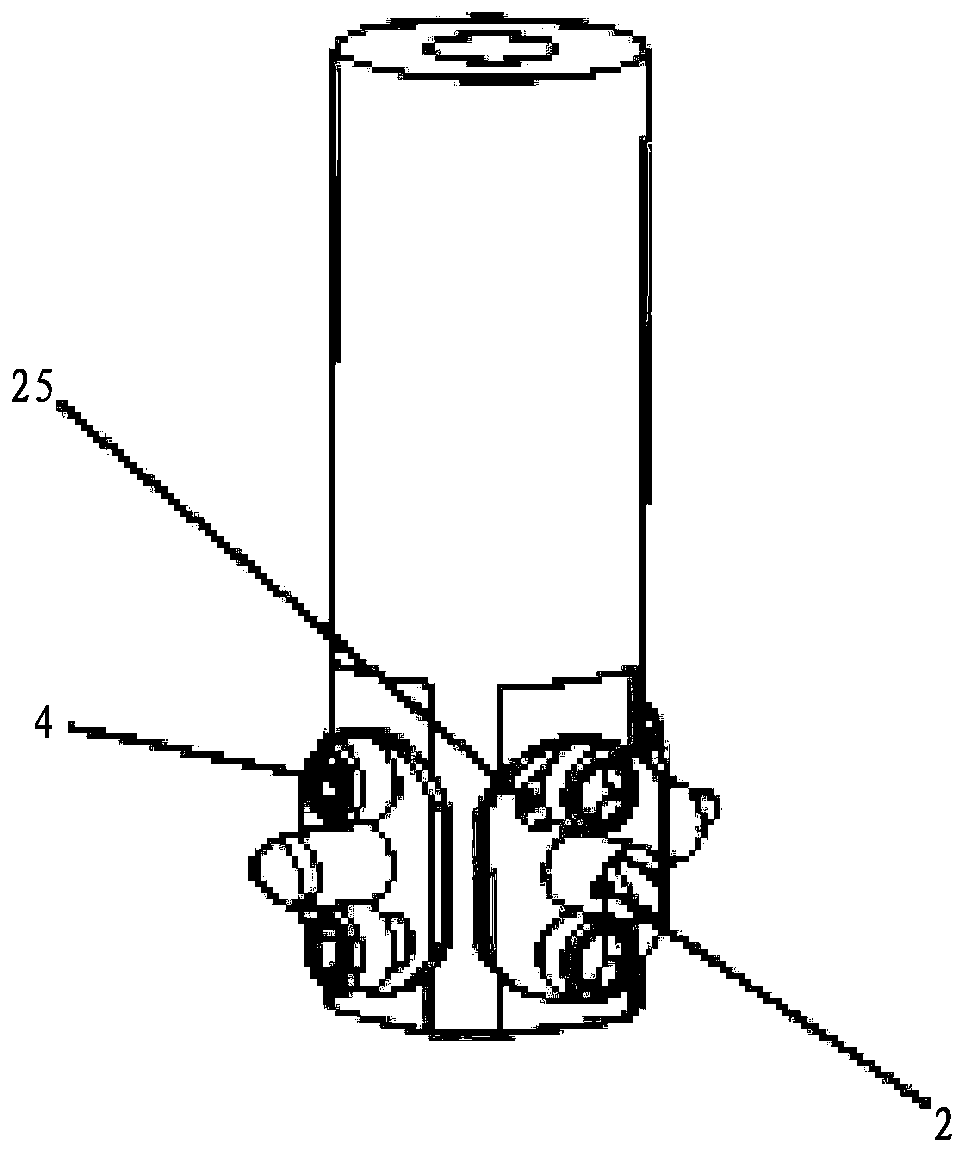

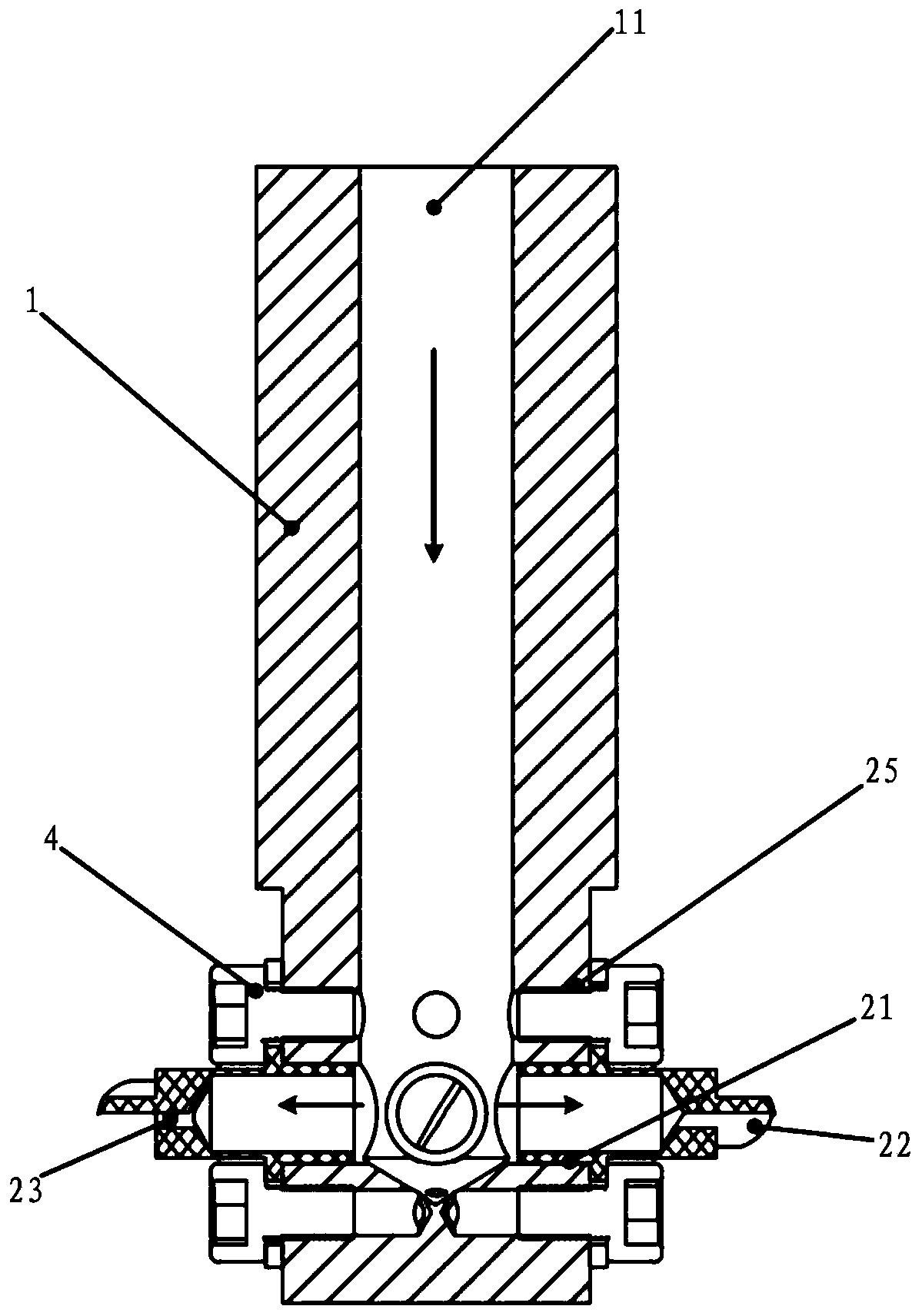

[0030] refer to Figure 1 to Figure 4 , the present embodiment relates to a processing device for processing large-lead nuts, including a hollow clamping rod 1, a cathode piece 2 and a nut 3, and the cathode piece 2 is installed on the outer circumference of the lower end of the hollow clamping rod 1; the hollow clamping The axis of the holding rod 1 coincides with the axis of the nut 3, and the normal direction of the cathode piece 2 is the same as the tangential direction of the spiral raceway 31 of the nut 3; the hollow clamping rod 1 is provided with a slot 11 for an external electrolyte , and the lower end of the hollow clamping rod 1 is provided with a liquid spray port 23 communicating with the slot 11, and the electrolyte is directly sprayed to the cathode from the liquid spray port in a direction parallel to the outer surface of the cathode sheet 2 and along the outer surface of the cathode sheet 2. In the processing area between the sheet 2 and the nut 3; the hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com