Lithium ferrosilicon silicate/carbon composite cathode material and preparation method thereof

A technology of lithium ferrous silicate and positive electrode materials, which is applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve the problems of low electrical conductivity and poor high-rate performance, and achieve low cost, improved electrical conductivity, and increased The effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of Example 1 Lithium Ferrous Silicate / Carbon Composite Positive Electrode Material

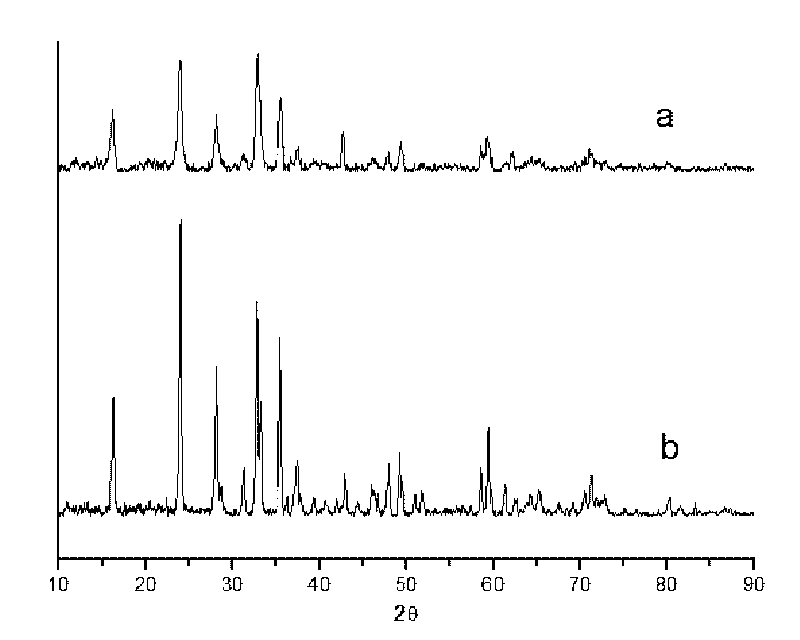

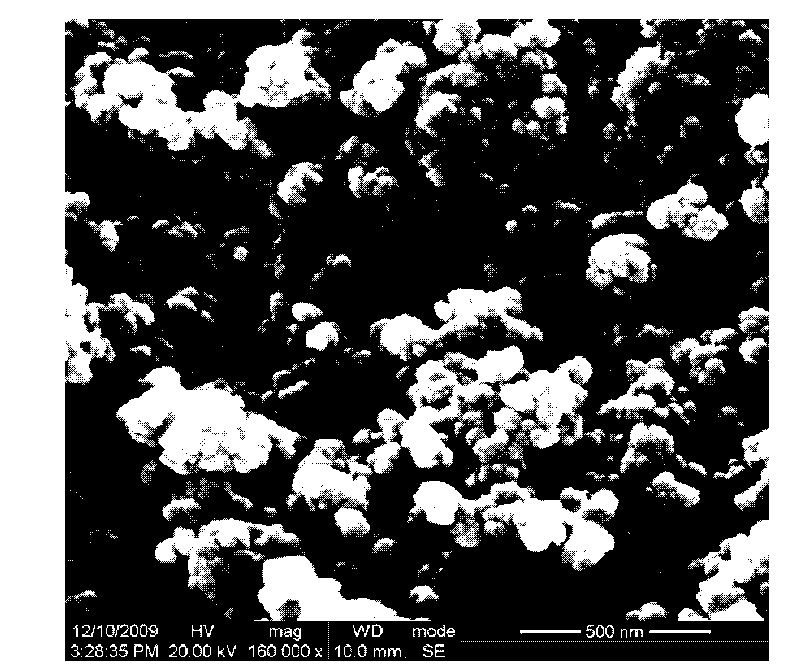

[0039] Add ferrous oxalate (7.2177g), silicon dioxide (2.4153g), lithium carbonate (2.9705g) and asphalt into a ball mill jar, and after ball milling and mixing in acetone, vacuum dry at 80°C to obtain a precursor. The precursor was pressed into tablets, pre-fired at 350° C. for 5 hours in argon, and then fired at 700° C. for 10 hours to obtain a lithium ferrous silicate / carbon composite positive electrode material. According to the elemental analysis test, the content of carbon in the obtained lithium ferrous silicate / carbon composite positive electrode material is 8.7%. X-ray diffraction pattern see figure 1 , SEM image see figure 2 .

Embodiment 2

[0040] The preparation of embodiment 2 comparative sample ferrous silicate

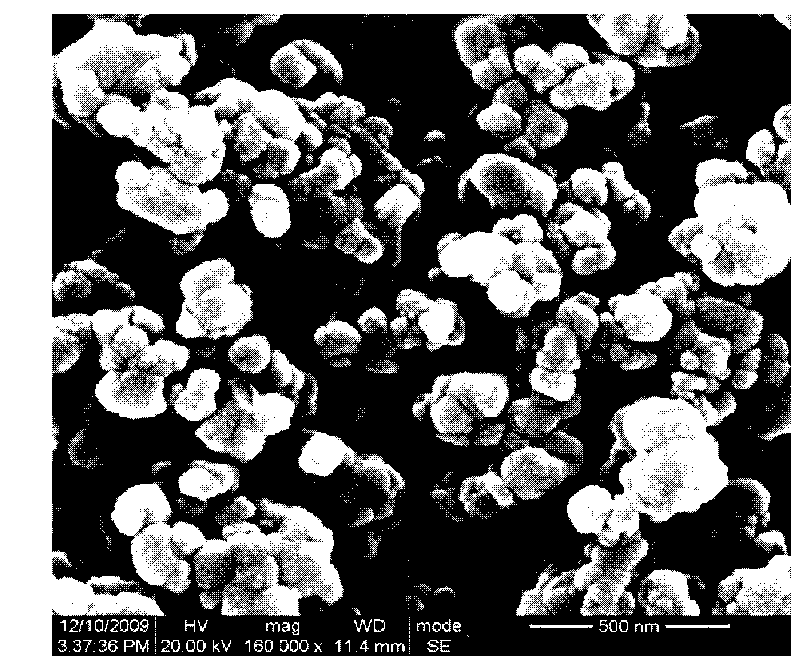

[0041] Add ferrous oxalate (7.2177g), silicon dioxide (2.4153g) and lithium carbonate (2.9705g) into a ball mill jar, and after ball milling and mixing in acetone, vacuum dry at 80°C to obtain a precursor. The precursor was pressed into tablets, pre-fired at 350° C. for 5 hours in argon, and then fired at 700° C. for 10 hours to obtain a lithium ferrous silicate composite positive electrode material. X-ray diffraction pattern see figure 1 , SEM image see image 3 .

[0042] figure 1 It can be seen that the diffraction peak intensity of the sample obtained in Example 1 is lower than that of the sample obtained in Example 2, and the half width of the diffraction peak is smaller. According to the Scherrer formula, the grain size is inversely proportional to the half-peak width. It can be seen from the following that the crystal grains of carbon-doped lithium ferrous silicate tend to decrease compare...

Embodiment 3

[0044] Example 3 Preparation of Lithium Ferrous Silicate / Carbon Composite Positive Electrode Material

[0045] Add ferrous oxalate (7.5747g), silicon dioxide (2.4153g), lithium carbonate (3.0470g) and asphalt into a ball mill jar, ball mill and mix in acetone, and vacuum dry at 80°C to obtain a precursor. The precursor was pressed into tablets, pre-fired at 350° C. for 5 hours in argon, and then fired at 700° C. for 10 hours to obtain a lithium ferrous silicate / carbon composite positive electrode material. According to the elemental analysis test, the content of carbon in the obtained lithium ferrous silicate / carbon composite positive electrode material is 8.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com