Optical fiber extrinsic Fabry-Perot interference ultrasonic sensing and detection device

A detection device, ultrasonic sensing technology, applied in the direction of measuring device, measuring ultrasonic/sonic/infrasonic, testing dielectric strength, etc., to achieve the effect of easy packaging, convenient mass production, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

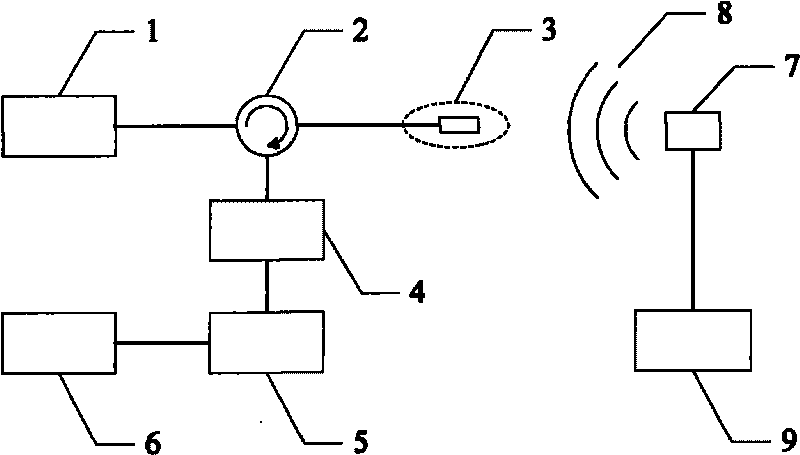

[0021] Embodiment one: see figure 1 , the optical fiber Fabry-Perot ultrasonic sensing device includes: a light source 1, the light source 1 is connected to an optical fiber circulator 2, and an interface of the optical fiber circulator 2 is connected to an optical fiber Fabry-Perot ultrasonic Sensor 3, another interface connects an oscilloscope 6 through a photoelectric conversion module 4 and a signal amplification module 5, and a signal generator 9 connects a piezoelectric transducer 7, and this piezoelectric transducer produces ultrasonic signal 8, transmits to The Fabry-Perot ultrasonic sensor 3; the light source 1 shown is a 1550nm light source, and the fiber optic circulator 2 is a 1550nm fiber optic circulator.

Embodiment 2

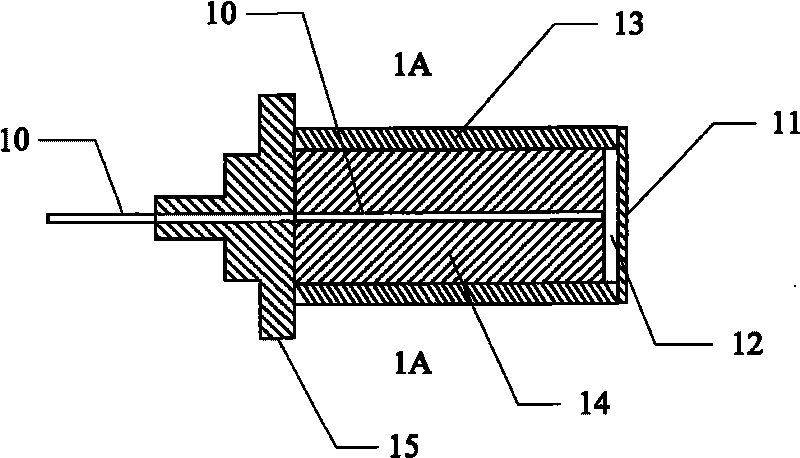

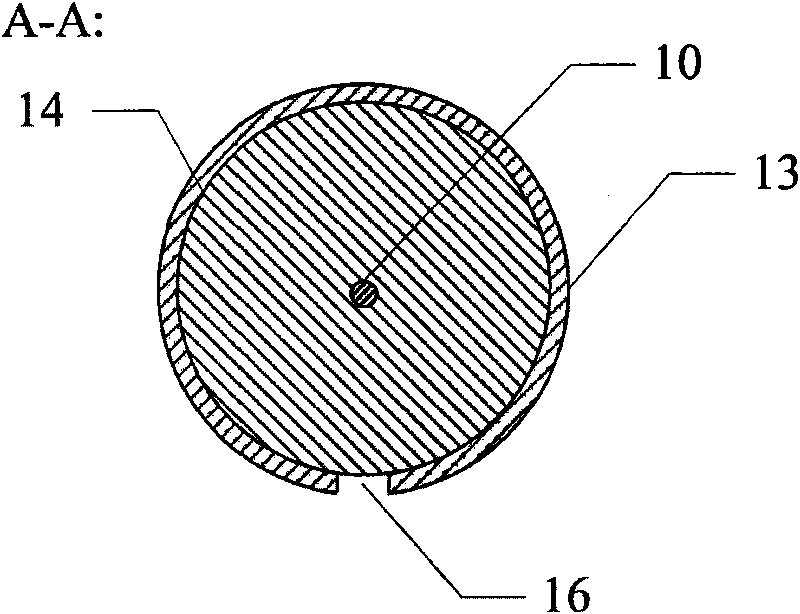

[0022] Embodiment two: see figure 2 , the above-mentioned present embodiment is the same as Embodiment 1, and the special features are as follows: the basic structure of the optical fiber Fabry-Perot ultrasonic sensor is: a single-mode optical fiber 10 is inserted in an inner ceramic sleeve 14 and then an outer jacket The ceramic sleeve 13 has a metal base 15 and a quartz vibrating membrane 11 at the two ends of the inner ceramic sleeve 14 and the outer ceramic sleeve 13 respectively. The inner end surface of the single-mode optical fiber 10, the inner surface of the quartz vibrating membrane 11, the inner wall surface of the outer ceramic sleeve 13 and the end surface of the inner ceramic sleeve 14 form a Fabry-Perot cavity 12; the Fabry-Perot The cavity length of the cavity is the distance from the end face of the single-mode optical fiber 10 to the inner surface of the quartz vibrating membrane 11; the inner diameter of the outer ceramic sleeve 13 of the optical fiber Fabr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com