Indium lanthanum titanium oxide transparent conductive film

A transparent conductive film, titanium oxide technology, applied in the field of optoelectronics, to achieve the effects of good thermal stability, good electrical conductivity, and improved device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

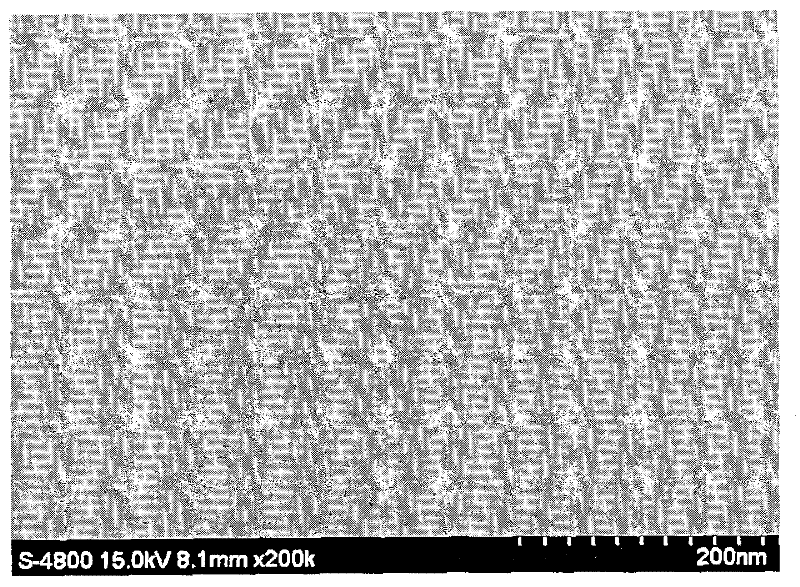

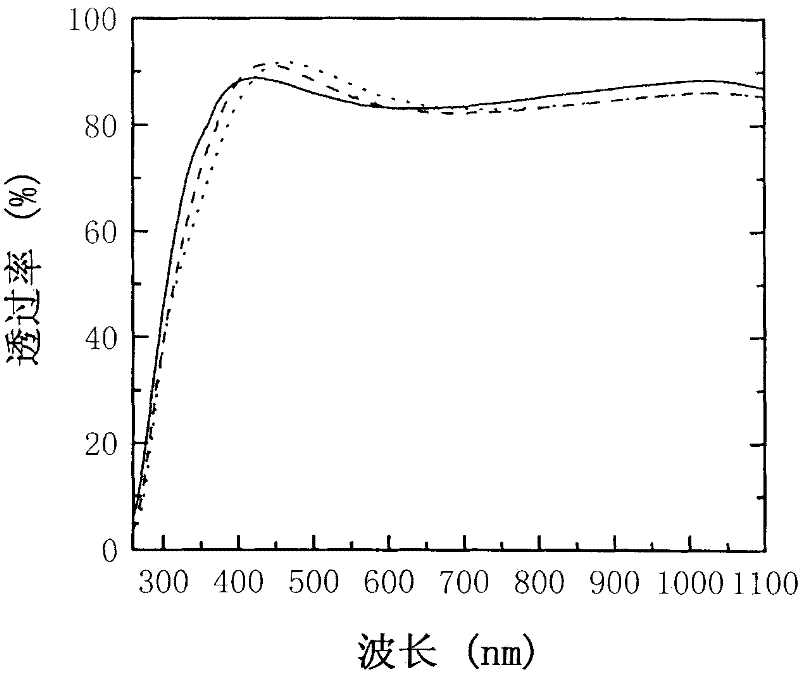

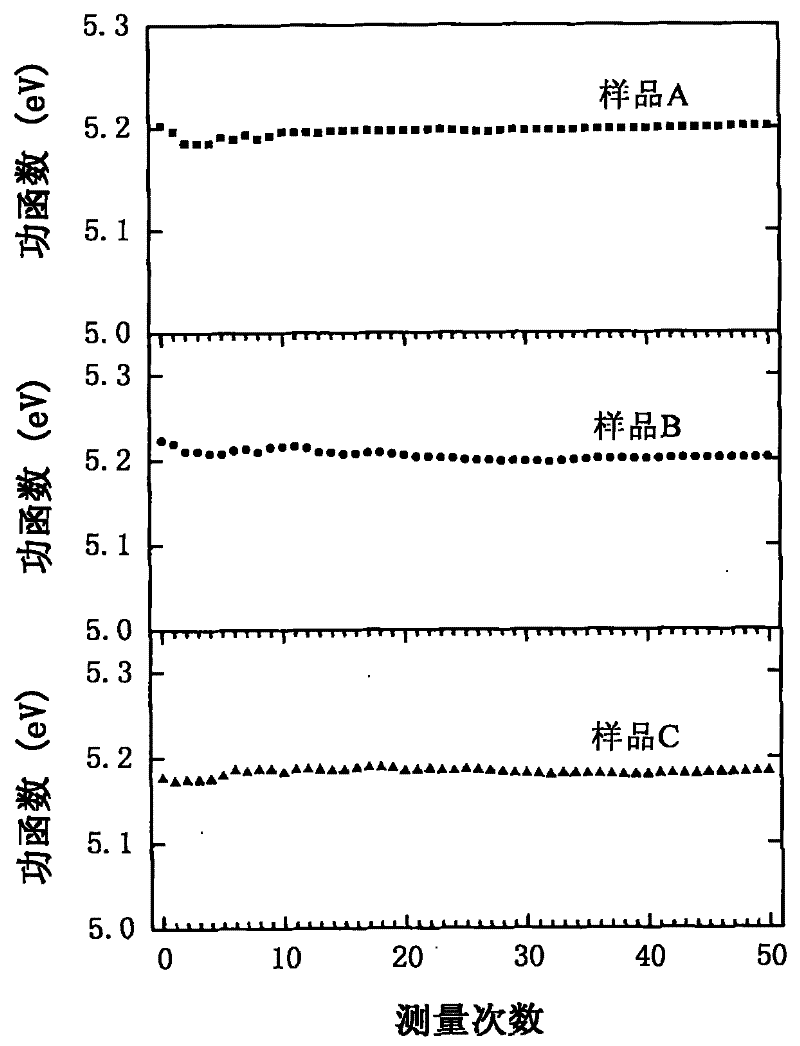

Image

Examples

Embodiment 1

[0019] In the ZZS660 box-type high-vacuum coating machine produced by Chengdu Vacuum Machinery Factory, the electron beam deposition process is used to prepare ILTO transparent conductive film. The specific steps are as follows:

[0020] a. The glass substrate was ultrasonically cleaned in ALCONOX cleaning agent, acetone and deionized water for 10 minutes respectively, dried with dry nitrogen and placed in a vacuum chamber, and the vacuum chamber was evacuated to 2.0×10 -3 Pa, and then heat the glass substrate, the temperature range is 60-400°C.

[0021] b. Fill the vacuum chamber with oxygen and argon with a purity of 99.99%, and control the volume ratio of the charged oxygen to argon to be 0.1:1 to 2:1, and use a pressure controller to control the pressure in the vacuum chamber at 7×10 -3 ~4×10 -1 within the Pa range.

[0022] c. In order to avoid the influence of the surface composition of the glass substrate on the film-forming performance of ILTO, a layer of aluminum ox...

Embodiment 2

[0029] In the vacuum coating machine, the vacuum thermal evaporation process is used to prepare the ILTO transparent conductive film. The specific steps are as follows:

[0030] a. The quartz substrate was ultrasonically cleaned in ALCONOX cleaning agent, acetone and deionized water for 10 minutes respectively, dried with dry nitrogen and placed in a vacuum chamber, and the vacuum chamber was evacuated to 2.0×10 -3 Pa, and then heat the substrate at a temperature of 60-400°C.

[0031] b. Fill the vacuum chamber with high-purity oxygen and argon, and control the volume ratio of oxygen and argon to be 0.1:1 to 2:1. After filling the gas, control the pressure in the vacuum chamber to be 7×10 -3 ~4×10 -1 within the Pa range.

[0032] c. Using metal In, La and Ti as raw materials, the ILTO thin film was deposited by three-source co-evaporation, in which the evaporation rate of metal In was 0.2-3nm / s, the evaporation rate of La was 0.04-1nm / s, Ti The evaporation rate is 0.04-1nm / ...

Embodiment 3

[0034] In a magnetron sputtering vacuum coating machine, a magnetron sputtering process is used to prepare an ILTO transparent conductive film on a glass substrate. The specific steps are as follows:

[0035] a. The glass substrate was ultrasonically cleaned in ALCONOX cleaning agent, acetone and deionized water for 10 minutes respectively, dried with dry nitrogen and placed in a vacuum chamber, and the vacuum chamber was evacuated to 2.0×10 -3 Pa, and then heat the glass substrate, the temperature range is 60-400°C.

[0036] b. Filling the vacuum chamber with oxygen and argon with a purity of 99.99%, controlling the volume ratio of the charged oxygen to argon to be 0.1:1 to 2:1, and controlling the pressure in the vacuum chamber to be 7×10 -3 ~4×10 -1 within the Pa range.

[0037] c. In order to avoid the influence of the surface composition of the substrate on the film-forming performance of ILTO, a layer of SiO is first grown on the substrate 2 , the thickness is 5-200nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron work function | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com