Aluminate red fluorescent powder and preparation method thereof

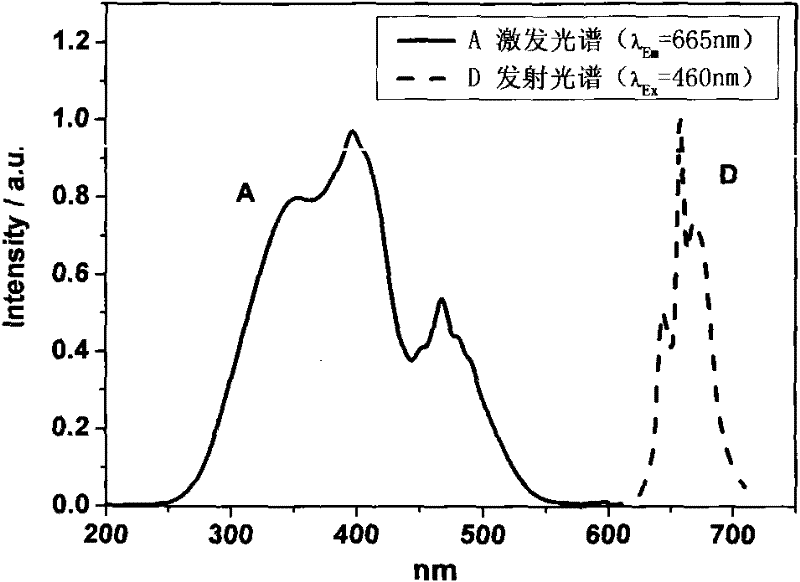

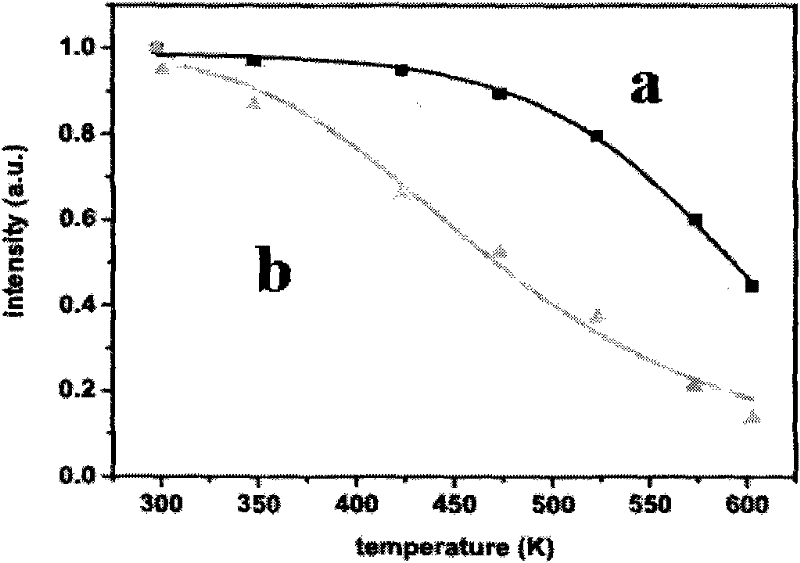

A technology of red fluorescent powder and aluminate, which is applied in chemical instruments and methods, luminescent materials, sustainable buildings, etc., can solve problems such as high cost, complicated circuit design, and immature technology, and achieve good thermal stability and chemical stability. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) 1mol SrCO 3 , 5.994mol Al 2 o 3 , 0.006mol MnO 2 , 0.006mol MgO and 0.35964mol H 3 BO 3 Mix, then put the mixture into a roller bottle machine and grind for 5h to obtain a phosphor precursor;

[0026] 2) Put the phosphor precursor into a high-temperature furnace for sintering in an air atmosphere. The sintering temperature is raised at a rate of 3°C / min. When the sintering temperature reaches 200°C, keep for 2 hours; continue to heat up at a rate of 3°C / min. Then when the sintering temperature reaches 1350°C, keep it for 4h; finally, drop it to room temperature at a cooling rate of 3°C / min;

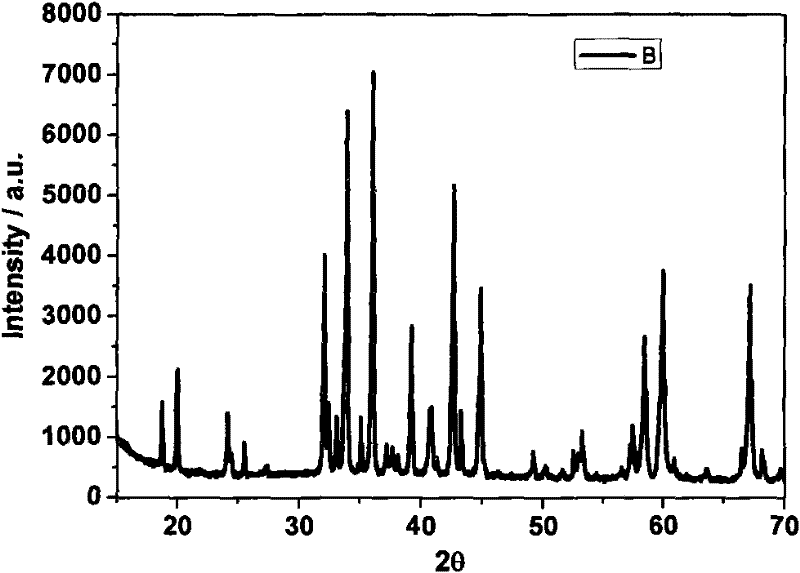

[0027] 3) The obtained sintered material is ball milled with a ball mill, the time of ball milling is 3h, and the number of revolutions is 180r / min; after the ball milling is completed, the red fluorescent powder SrAl is obtained 11.988 mn 0.006 Mg 0.006 o 19 .

Embodiment 2

[0029] 1) 1mol SrCO 3 , 5.4mol Al 2 o 3 , 0.6mol MnO 2 , 0.6mol MgO and 0.324molH 3 BO 3 Mix, and then put the mixture into a roller bottle machine and grind for 15 hours to obtain a phosphor precursor;

[0030] 2) Put the phosphor precursor into a high-temperature furnace for sintering in a pure oxygen atmosphere. The sintering temperature is raised at a rate of 3°C / min. When the sintering temperature reaches 200°C, keep for 2 hours; continue at a rate of 3°C / min. Raise the temperature, and then keep it for 4 hours when the sintering temperature reaches 1350°C; finally, lower the temperature to room temperature at a cooling rate of 5°C / min;

[0031] 3) The obtained sintered product is ball milled with a ball mill, the time of ball milling is 10h, and the number of revolutions is 180r / min; after the ball milling is completed, the red fluorescent powder SrAl is obtained 10.8 mn 0.6 Mg 0.6 o 19 .

Embodiment 3

[0033] 1mol SrCO 3 , 5.7mol Al 2 o 3 , 0.3mol MnO 2 , 0.3mol MgO and 0.342molH 3 BO 3 Mix, then put the mixture into a ball mill and grind for 8h to obtain a phosphor precursor;

[0034] 2) Put the phosphor precursor into a high-temperature furnace for sintering in an air atmosphere. The sintering temperature is raised at a rate of 4°C / min. When the sintering temperature reaches 150°C, keep for 2 hours; continue to increase the temperature at a rate of 4°C / min. , and then when the sintering temperature reaches 1450°C, it is kept for 4h; finally, it is lowered to room temperature at a cooling rate of 4°C / min;

[0035] 3) Grinding the obtained sintered product with a roller bottle machine, the crushing time is 10h, and the rotation speed is 200r / min; after the ball milling is completed, the red fluorescent powder SrAl is obtained 11.4 mn 0.3 Mg 0.3 o 19 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com