Elastic anti-corrosion coating

An anti-corrosion coating and elastic technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of light resistance, poor cement adhesion, water resistance, poor saponification resistance, etc., and achieve high elongation at break, excellent adhesion, The effect of excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In a preferred embodiment of the present invention, the organopolysiloxane, fillers, and pigments are premixed first, and after grinding, the mixture is transferred to a vacuum kneader, heated to 50-200°C and kneaded for 3-120 minutes under vacuum, and then added After mixing agent, auxiliary agent and diluent, knead for 5-60 minutes to obtain the desired anti-corrosion elastic coating. Embodiment 1, transparent elastic anticorrosion coating

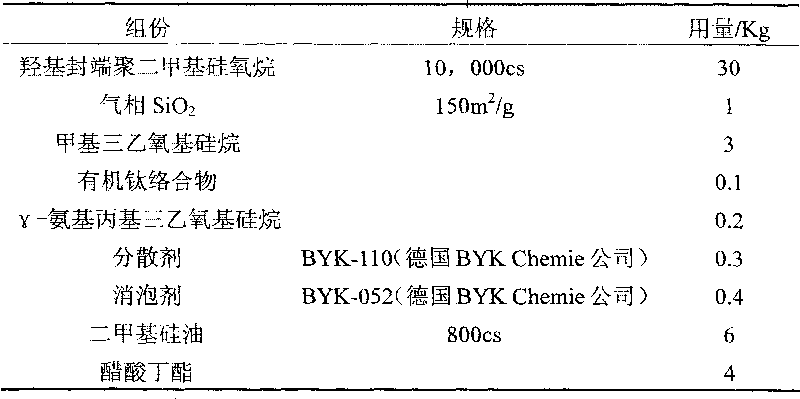

[0043] The formulation and properties of the transparent elastic anticorrosion paint provided by the present invention are listed in Table 1 and Table 2 respectively.

[0044] Table 1. Formula 1 of transparent elastic anticorrosion coating

[0045]

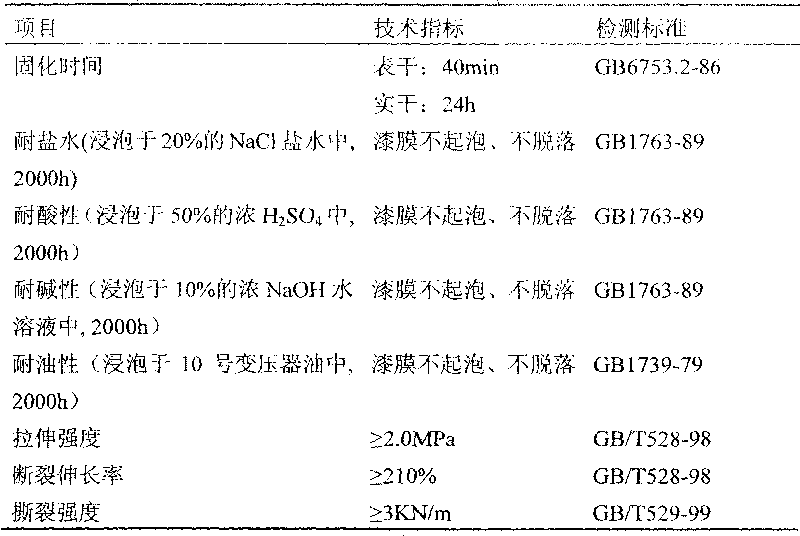

[0046] Table 2. Performance test

[0047]

Embodiment 2

[0048] Embodiment 2, be used for bridge weather-resistant type elastic anticorrosion coating

[0049] The formulation and properties of the second transparent elastic anticorrosion coating provided by the present invention are listed in Table 3 and Table 4 respectively.

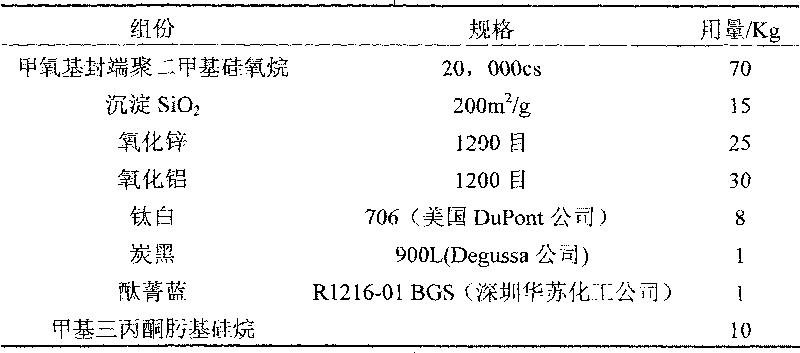

[0050] Table 3. Formulas of weather-resistant elastic anti-corrosion coatings for bridges

[0051]

[0052]

[0053] Table 4. Performance test

[0054]

Embodiment 3

[0055] Embodiment 3, be used for elastic anticorrosion coating of steel structure

[0056] The formulation and properties of the third transparent elastic anticorrosion coating provided by the present invention are listed in Table 5 and Table 6 respectively.

[0057] Table 5. Formulation of elastic anticorrosion coatings for steel structures

[0058]

[0059] Table 6. Performance test

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com