Method for preparing hundred nano grade narrow line width holographic grating photoresist pattern with various features

A holographic grating and photoresist technology, which is applied to microlithography exposure equipment, photolithographic process of pattern surface, diffraction grating and other directions, can solve the problems of long electron beam exposure time and high cost, and achieves long time consumption and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

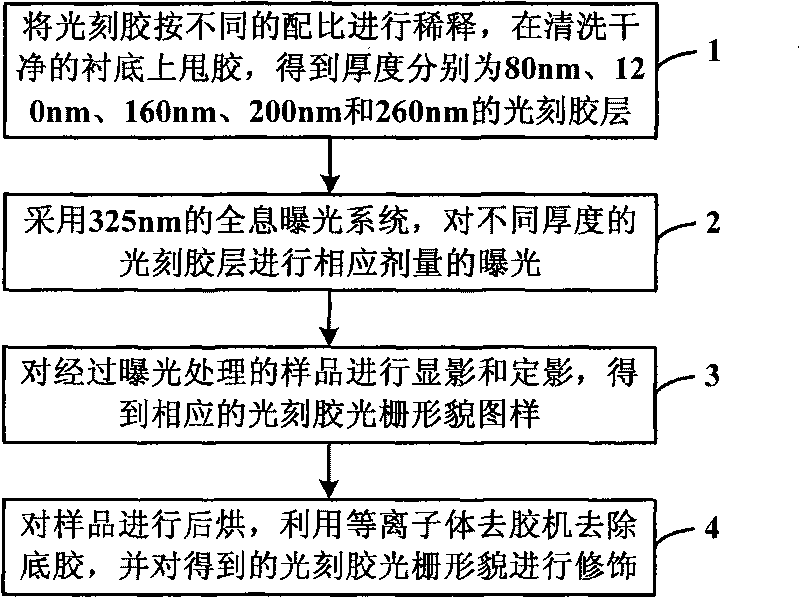

[0041] Such as figure 1 as shown, figure 1 It is a flow chart of a method for preparing a holographic grating photoresist pattern with a narrow line width of a hundred nanometers and various shapes provided by the present invention, and the method includes:

[0042] Step 1: Dilute the photoresist according to different proportions, and shake the glue on the cleaned substrate to obtain photoresist layers with thicknesses of 80nm, 120nm, 160nm, 200nm and 260nm;

[0043] Step 2: Use a 325nm holographic exposure system to expose photoresist layers with different thicknesses in corresponding doses;

[0044] Step 3: developing and fixing the exposed sample to obtain the corresponding photoresist grating pattern;

[0045] Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com