Lignin base skin core structure nanometer/micron fiber and preparation method thereof

A skin-core structure and lignin-based technology, applied in the field of materials, can solve the problems of low electrical conductivity, limited viscoelasticity of lignin solution, and inability to form lignin-based skin-core fibers, etc., and achieve the effect of simple preparation method and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Preparation of the core layer solution: put the mixture of 2.5g lignin and 2.5g polyacrylonitrile into 100g N,N-dimethylacetamide, stir to dissolve it completely, and become the lignin mixed solution;

[0030] 2. Preparation of cortex solution: put 5g of polylactic acid into 50g of N,N-dimethylformamide, stir to dissolve it completely, and become a polymer solution;

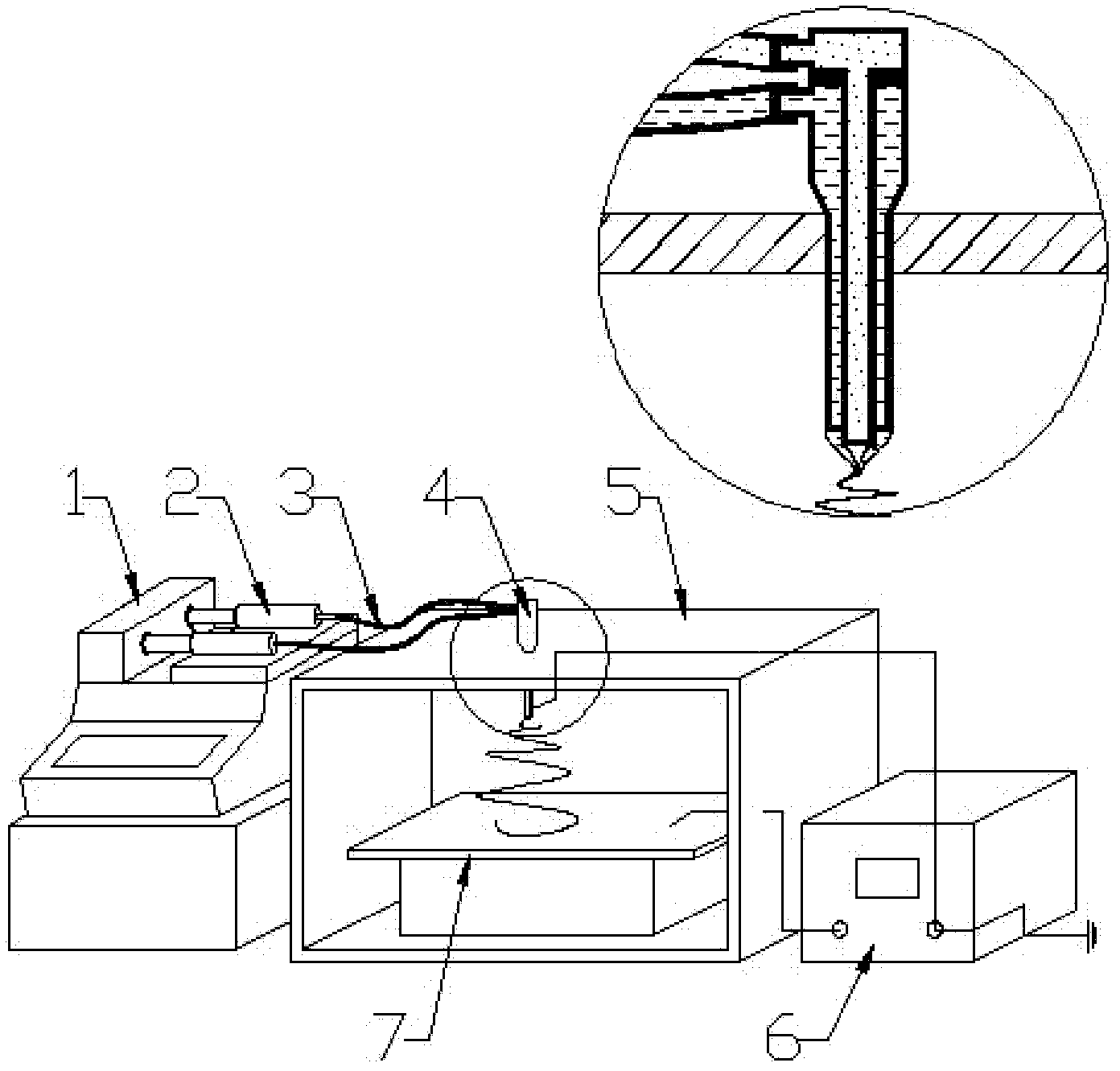

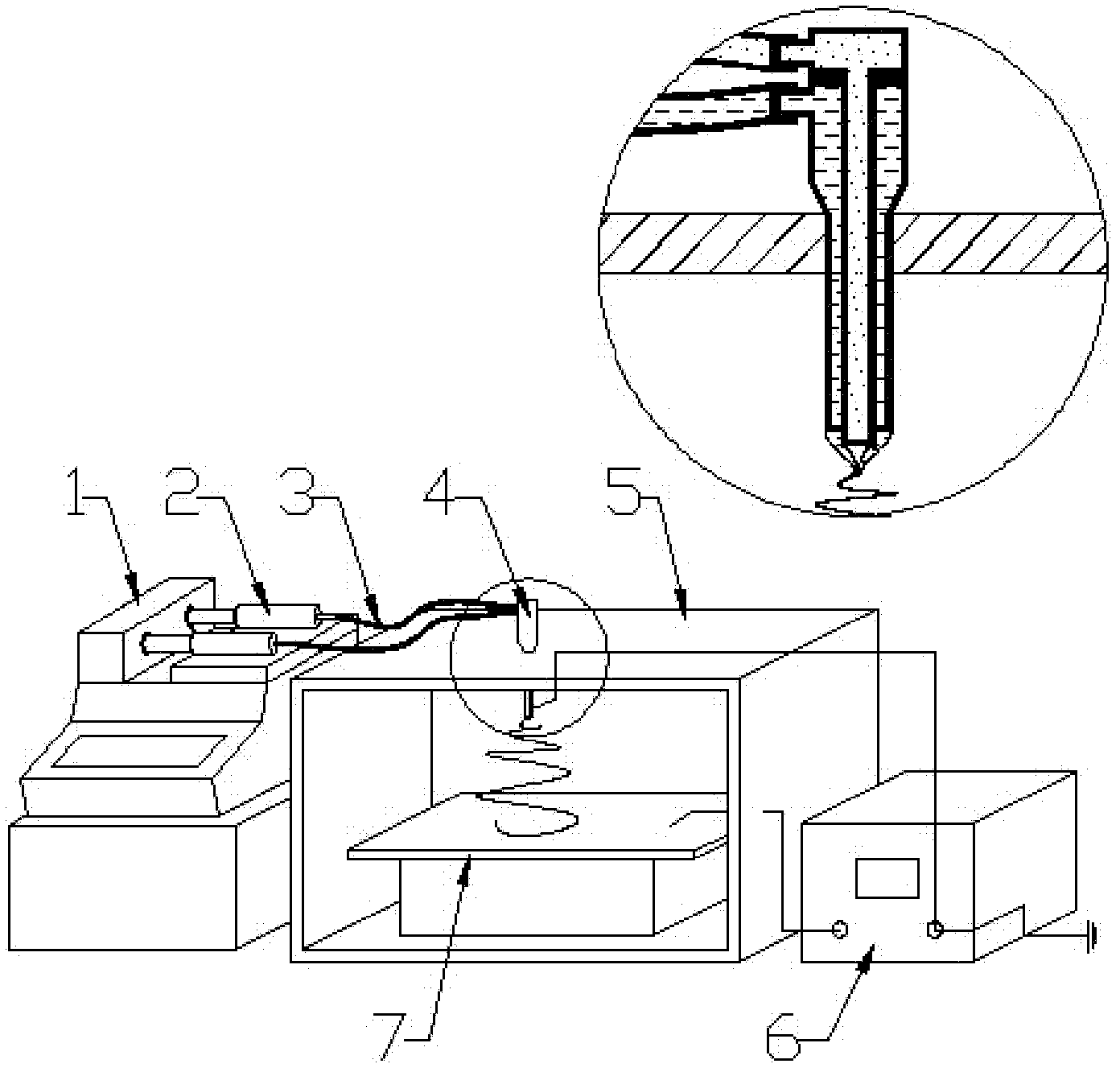

[0031] 3. Coaxial electrospinning: use such as figure 1In the shown coaxial electrospinning device, the positive and negative electrodes are respectively connected to the coaxial needle 4 and the collecting plate 7 , and the coaxial needle 4 and the collecting plate 7 are located in the constant temperature and humidity container 5 . The distance between the coaxial needle 4 of the electrospinning device and the grounded collecting plate 7 is 5cm, the inner diameter of the inner layer of the coaxial needle 4 is 0.1mm, and the inner diameter of the outer layer is 0.5mm (that is, the inner diameter of the...

Embodiment 2

[0033] 1. Preparation of the core layer solution: put 3.25g of lignin and 1.75g of polyurethane mixture into 50g of N,N-dimethylformamide, stir to dissolve it completely, and become a lignin mixed solution;

[0034] 2. Preparation of cortex solution: 5g of cellulose is put into 25g of lithium chloride / dimethylacetamide with a mass ratio of 7:93, and stirred to dissolve it completely to become a polymer solution;

[0035] 3. Coaxial electrospinning: use such as figure 1 In the shown coaxial electrospinning device, the positive and negative electrodes are respectively connected to the coaxial needle 4 and the collecting plate 7 , and the coaxial needle 4 and the collecting plate 7 are located in the constant temperature and humidity container 5 . The distance between the coaxial needle 4 of the electrospinning device and the grounded collection plate 7 is 25cm, the inner diameter of the coaxial needle 4 is 1mm, and the inner diameter of the outer layer is 2.5mm (that is, the i...

Embodiment 3

[0037] 1. Preparation of core layer solution: put the mixture of 4.5g lignin and 0.5g polyethylene oxide into 5g acetone, stir to dissolve it completely, and become a polymer solution and become a lignin mixed solution;

[0038] 2. Preparation of cortex solution: put 5g of cellulose acetate into 50g of acetic acid, stir to dissolve it completely, and become a polymer solution;

[0039] 3. Coaxial electrospinning: use such as figure 1 In the shown coaxial electrospinning device, the positive and negative electrodes are respectively connected to the coaxial needle 4 and the collecting plate 7 , and the coaxial needle 4 and the collecting plate 7 are located in the constant temperature and humidity container 5 . The distance between the coaxial needle 4 of the electrospinning device and the grounded collection plate 7 is 40 cm, the inner diameter of the coaxial needle 4 is 0.5 mm, and the inner diameter of the outer layer is 1.5 mm (that is, the inner diameter of the outer layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com