Biological activated carbon nano-fiber and preparation method thereof

A technology of biologically activated carbon and carbon nanofiber, which is applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., can solve problems such as weak interaction force, reduced biological activity of carbon fiber, and easy to dissociate and fall off. The method is simple and maintains Osteoconduction ability, effect of improving osteogenesis ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The specific implementation steps of the preparation method of the present invention are:

[0024] (a) Dissolve calcium salt and phosphate in deionized water respectively, wherein the molar concentration of calcium salt and phosphate are both 0.1 to 1.5 mol / L, and after aging for 4 to 10 days, stir mechanically, magnetically or ultrasonically Slowly add them into the organic solution of the polymer one by one to form a uniform spinning solution. The amount of calcium salt and phosphate is prepared according to the Ca / P ratio of the desired product calcium phosphate salt. The mass concentration of the polymer The amount of acid salt is prepared according to the Ca / P ratio of the desired product calcium phosphate salt, and the mass concentration of the polymer is 10-15%;

[0025] (b) Electrospinning is used to prepare polymer nanofiber membranes containing calcium salts and phosphates, wherein the inner diameter of the syringe needle is 0.5 to 1.5 mm, the applied electros...

Embodiment 1

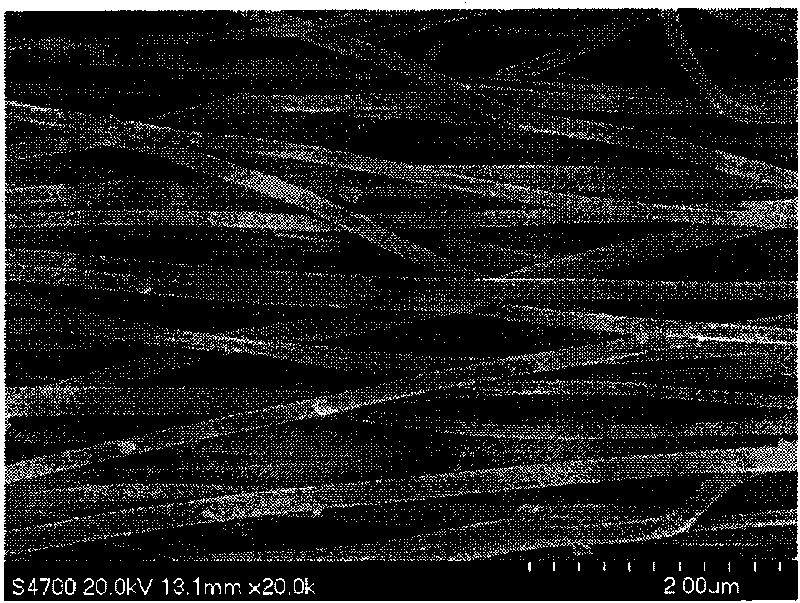

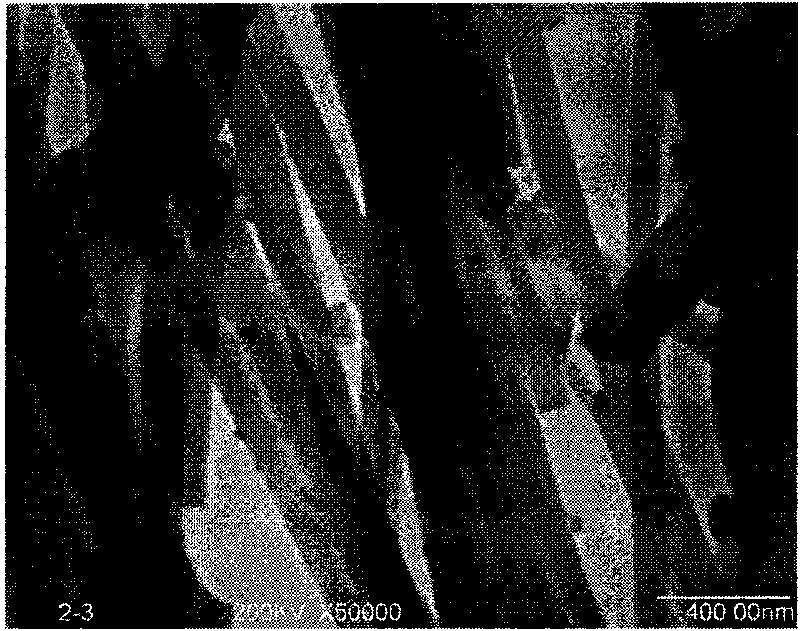

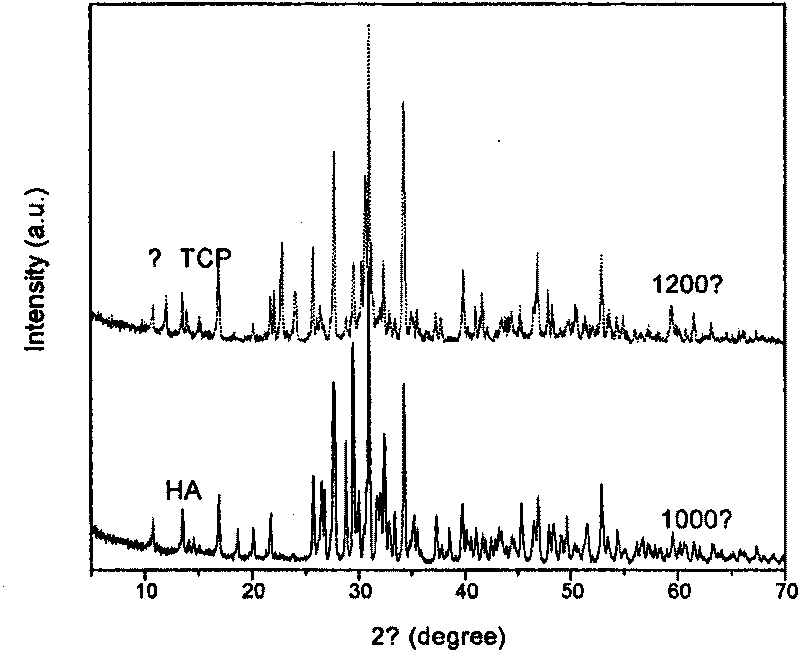

[0030]Dissolve 2.361g of calcium nitrate tetrahydrate and 1.143mL of triethylphosphoric acid in 10mL of deionized water respectively, and slowly add them dropwise to 100mL of polyacrylonitrile / dimethylformamide with a concentration of 10wt% after aging for 1 week solution, and then under ultrasonic stirring until a homogeneous solution was formed for electrospinning. During the electrospinning process, a No. 9 injection needle with an inner diameter of 0.9 mm was selected, the applied electrostatic voltage was 15 kV, the flow rate of the spinning solution was 0.4 mL / h, the receiving distance between the metal drum and the needle was 15 cm, and the outer diameter of the drum was 15 cm. The speed is 5m / s, and after 8 hours of spinning, a nanofiber film with a certain thickness and partial parallel orientation is obtained. The resulting electrospun nanofibrous membrane was pre-oxidized at 280 °C for 1 h. Finally, the stabilized composite nanofibers were sintered in a carbonizati...

Embodiment 2

[0032] Dissolve 2.629g of calcium nitrate tetrahydrate and 1.143mL of triethylphosphoric acid in 10mL of deionized water in turn, and slowly add them dropwise to 100mL of polyacrylonitrile / dimethylformaldehyde with a concentration of 10wt.% after aging for 1 week. amide solution, and then under ultrasonic stirring until a homogeneous solution was formed for electrospinning. During the electrospinning process, a No. 9 injection needle with an inner diameter of 0.9 mm was selected, the applied electrostatic voltage was 15 kV, the flow rate of the spinning solution was 0.4 mL / h, the receiving distance between the metal drum and the needle was 15 cm, and the outer diameter of the drum was 15 cm. The speed is 5m / s, and after 8 hours of spinning, a nanofiber film with a certain thickness and partial parallel orientation is obtained. The resulting electrospun nanofibrous membrane was pre-oxidized at 280 °C for 1 h. Finally, the stabilized composite nanofibers were sintered in a carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com