Intervertebral fusion device and method of preparing the same

An intervertebral cage and cuboid technology, which is applied in the application field of biomedical composite materials, can solve the problems of poor bone conduction, unstable mechanical properties, and increase the brittle fracture of the intervertebral cage, so as to reduce complications and enhance early fixation. Reasonable effect of braking action, shape and structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

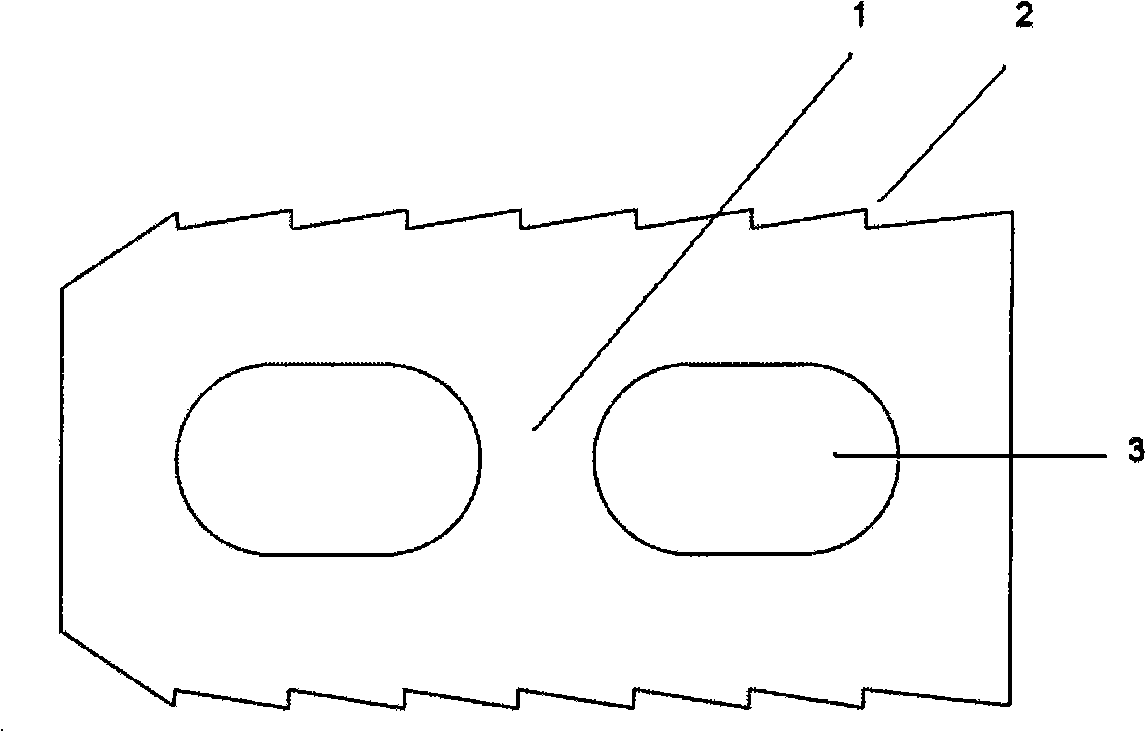

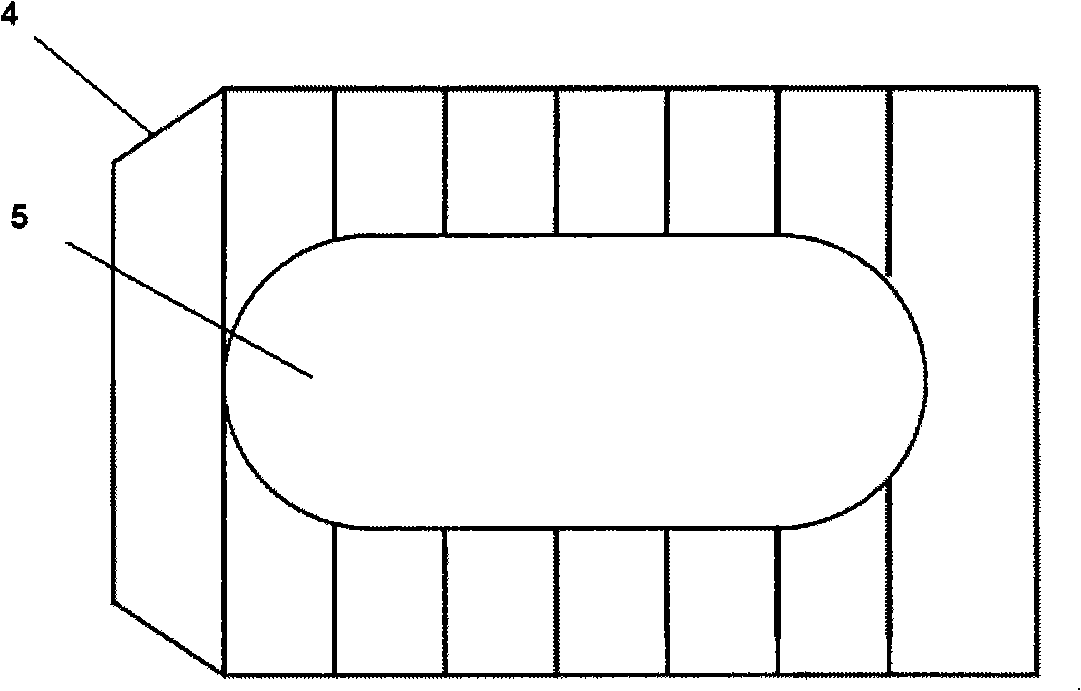

[0024] (1) Using diamond assorted files and CNC machine tools as the main tools, the three-dimensional carbon fiber braided C / C is processed into an external dimension of 25mm×14mm×11mm according to the structural requirements of the attached drawing, with 45° end chamfer 4 and upper and lower surfaces Intervertebral cage with triangular teeth 2 height 0.5 mm. The upper and lower through holes 5 (length 19mm, width 7mm) and drainage holes 3 (length 8mm, width 4mm, with a reinforcing rib 1 of width 3mm reserved between the two holes) are processed at a drilling speed of 12000 rpm and a small feed rate;

[0025] (2) SiC micropowder with an average particle size of 11 μm was selected as the medium, and the upper and lower surfaces of the intervertebral cage were pretreated by sandblasting for 2 minutes under a carrier pressure of 0.3 MPa;

[0026] (3) Select HA powder with a particle size of 38-75 μm, adopt subsonic plasma spraying method, spray powder at a distance of 70mm, volt...

Embodiment 2

[0030] (1) Using diamond assorted files and CNC machine tools as the main tools, the three-dimensional carbon fiber braided C / C was processed into an intervertebral fusion cage with an outer dimension of 25mm×11mm×11mm according to the structural requirements of the attached drawings. The upper and lower through holes 5 are 19mm long and 5mm wide, and other dimensions are the same as in Embodiment 1;

[0031] (2) Select Al with an average particle size of 140 μm 2 o 3 Sand is used as the medium, and the upper and lower surfaces of the intervertebral cage are pretreated by sandblasting for 1 min under a carrier pressure of 0.2 MPa;

[0032] (3) Under the conditions of spraying distance of 80mm, voltage of 42V, current of 700A and other spraying parameters unchanged, a HA coating with a thickness of 76μm can be prepared on the upper and lower surfaces of the intervertebral cage. Carry out vacuum heat treatment identical with above embodiment to product;

[0033] (4) A bone-li...

Embodiment 3

[0035](1) Process the C / C reinforced with three-dimensional carbon fiber braid into an intervertebral fusion device with an external dimension of 25mm×16mm×13mm according to the structural requirements of the attached drawings. The upper and lower through holes 5 are 19mm long and 8mm wide, and other dimensions are the same as in Embodiment 1.

[0036] (2) SiC sand with an average particle size of 140 μm was selected as the medium, and the upper and lower surfaces of the intervertebral cage were pretreated by sandblasting for 1 min under a carrier pressure of 0.2 MPa;

[0037] (3) When the spraying distance used in Example 2 was adjusted to 110 mm, and the moving speed of the spray gun was adjusted to 100 mm / s, an HA coating with a thickness of 142 μm was prepared on the upper and lower surfaces of the intervertebral cage. Carry out vacuum heat treatment identical with above embodiment to product;

[0038] (4) A bone-like apatite layer was prepared on the surface of the HA co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com