Method for preparing homogeneous phase strong alkali anion exchange membrane by radiation grafting method

A technology of anion exchange membrane and radiation grafting, which is applied in the field of preparation of homogeneous strong basic anion exchange membrane, can solve the problems of electrochemical performance such as the decrease of electrical conductivity and ion selectivity, and achieve the purpose of increasing preparation cost and membrane resistance. Low, high ion selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

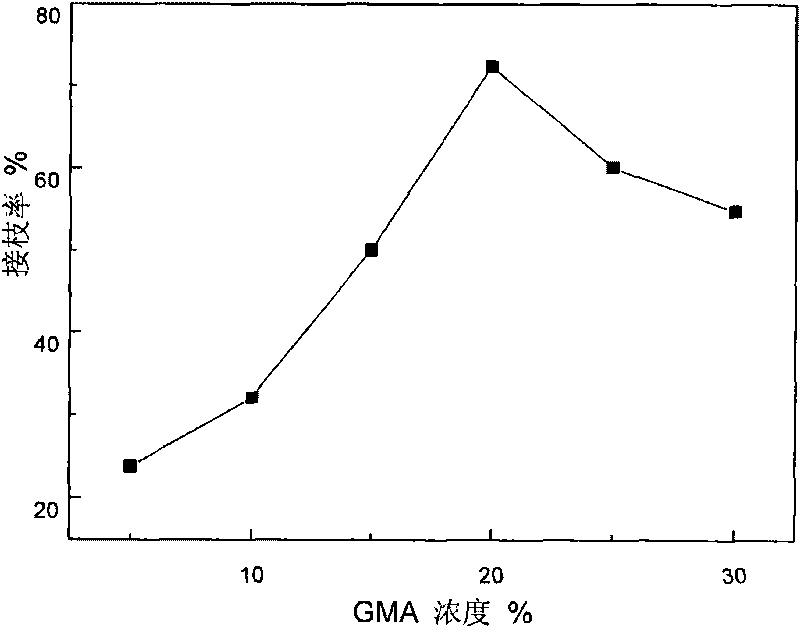

[0018] (1) First prepare the graft liquid reaction solution of the different grafting monomer concentrations of the volume ratio GMA: DMF=5: 95, 10: 90, 15: 85, 20: 80, 25: 75, 30: 70, and add Inhibitor copper sulfate, its weight percentage concentration is 0.015%.

[0019] (2) Then the polyethylene film is cleaned with acetone and dried to constant weight, and the weighed film is respectively placed in the above-mentioned containers containing grafting reaction solutions with different monomer concentrations, and vacuumized to remove the reaction solution. Dissolved oxygen in the solution is placed in a cobalt source chamber for irradiation after sealing; the total irradiation dose is 5-20kGy, and the irradiation dose rate is 1.5kGy / h, and the grafting rates of the obtained grafted films are respectively: 5kGy, 52%; 10kGy, 61.2%; 15kGy, 66.3%; 20kGy, 67.8%. The mensuration of graft rate (G) adopts weighing method, and calculation formula is as follows: (Note: W in the form...

Embodiment 2

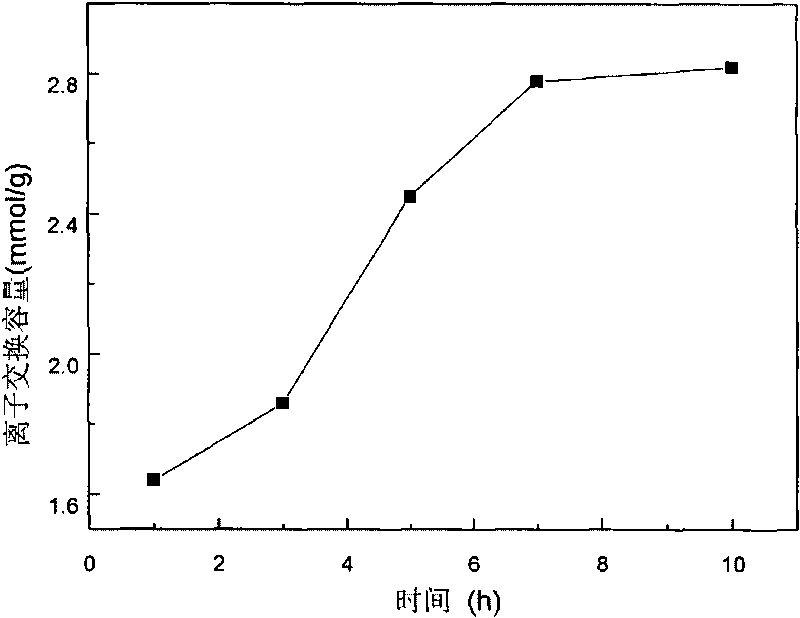

[0021] Example 2: The grafted film obtained in Example 1 with a graft rate of 72.6% is immersed in a 33% trimethylamine aqueous solution to introduce an anion exchange group, and the reaction times are 1, 3, 5, and 7 , 10 hours, the reaction temperature was 50°C, and the reaction was carried out under stirring. According to the amount of trimethylamine introduced into the grafted membrane at different reaction times, the ion exchange capacity of the prepared homogeneous membrane was calculated. figure 2 is the corresponding relationship between the ion exchange capacity of the homogeneous membrane and the amination time. The exchange capacity was determined by titration. (For the specific method, please refer to the national standard: GB / T 5760-2000, Hydrogen-oxygen type strong anion exchange resin exchange capacity determination method)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com