Low-temperature cured terminal carboxyl polyester resin for mixed powder coating and preparation method thereof

A carboxyl-terminated polyester and powder coating technology, applied in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of low glass transition temperature, high resin melt viscosity, easy caking, etc., and achieve excellent flow Flat performance, good impact performance, good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

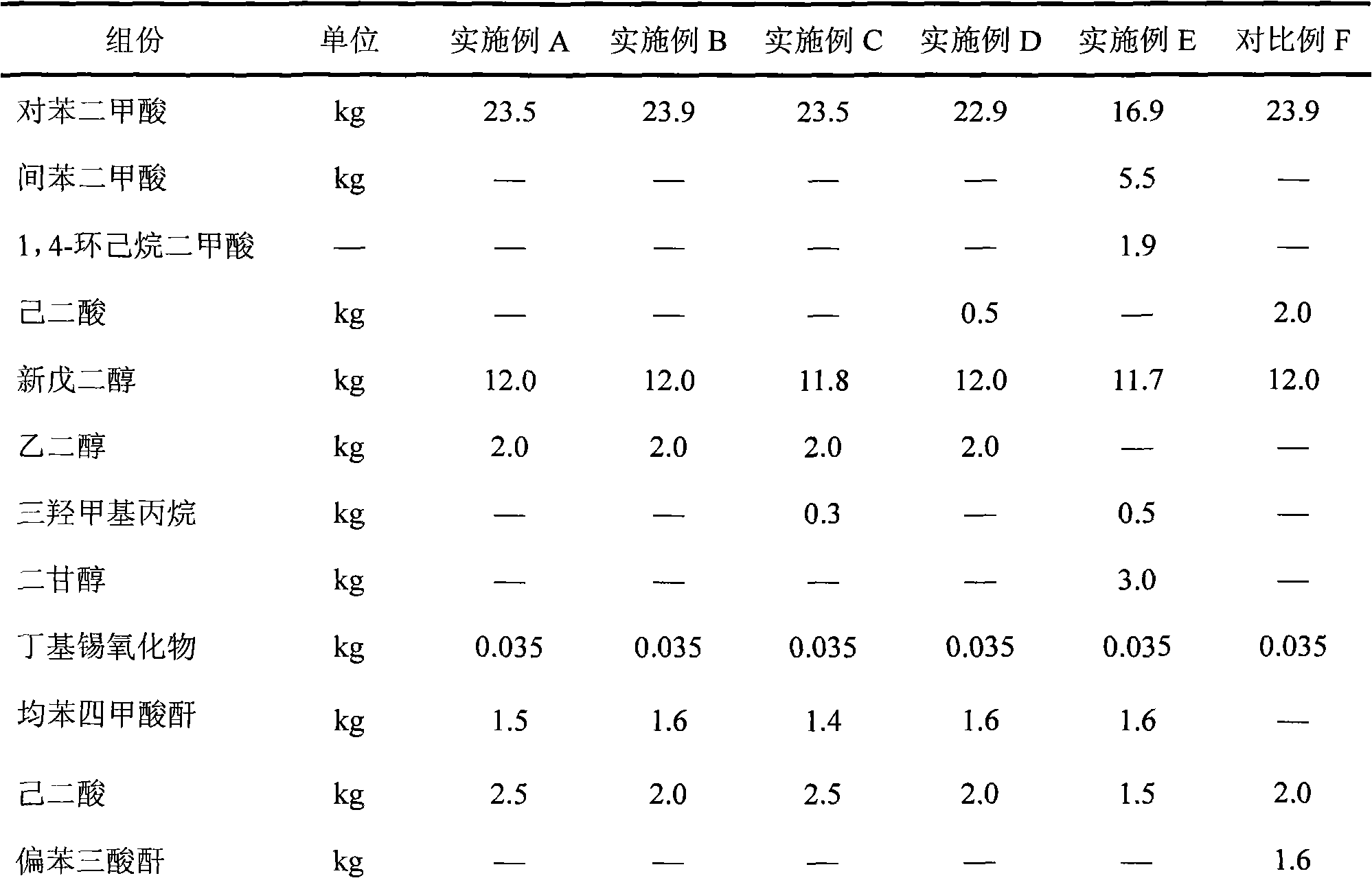

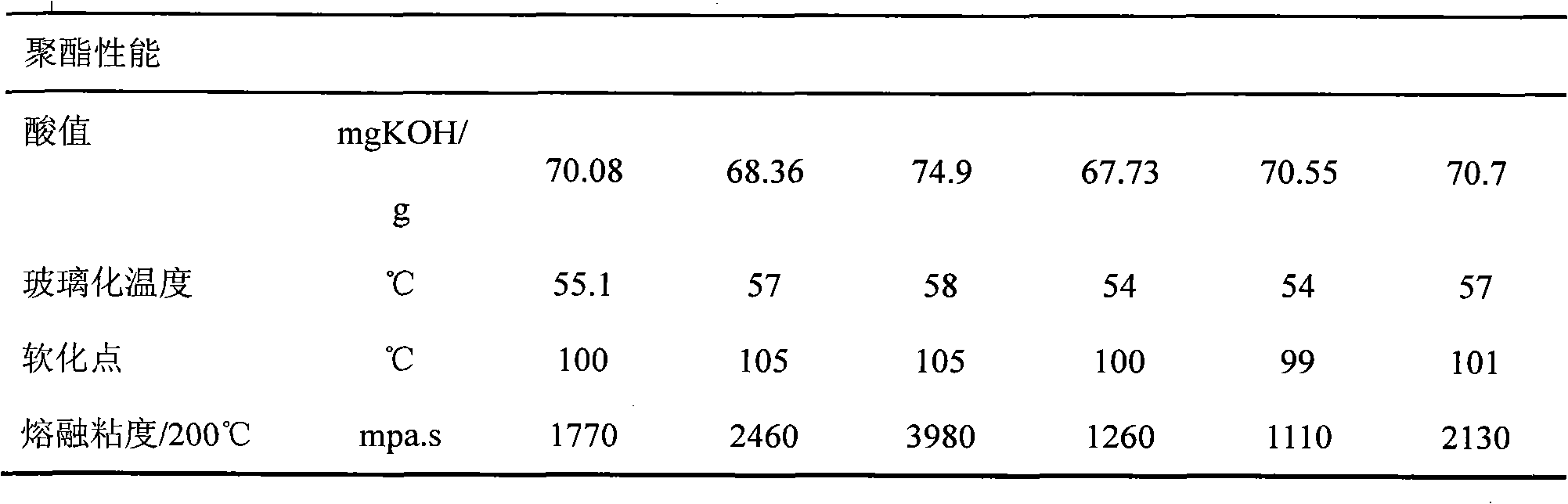

[0016] In a 50L reactor equipped with a heating device, an agitator and a distillation column, add neopentyl glycol, diethylene glycol, ethylene glycol, and trimethylolpropane in proportions listed in Table 1, and heat up until the material melts Finally, add terephthalic acid, isophthalic acid, 1,4-cyclohexanedimethanol, adipic acid, and butyl tin oxide in sequence, and continue to heat up the reaction with nitrogen gas. At about 180°C, esterified water begins to be formed and distilled out. Then gradually raise the temperature to 250°C, react for 5-10 hours until 95% of the esterified water is discharged, the acid value reaches 9-27mgKOH / g, vacuum polycondensation for 0.5-5h, the acid value reaches 3-15mgKOH / g; finally add Proportioned amount of acidolysis agent is used for capping, reacting for 0.5-3 hours, when the reaction reaches an acid value of 60-85 mgKOH / g, the reaction can be stopped by controlling the finally synthesized polyester resin in the following range: acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com