Ni-Ta binary block body metal glass

A technology of metallic glass and bulk metal, applied in the field of new materials, can solve the problems of arbitrary composition selection and complex optimization, and inability to prepare bulk metallic glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

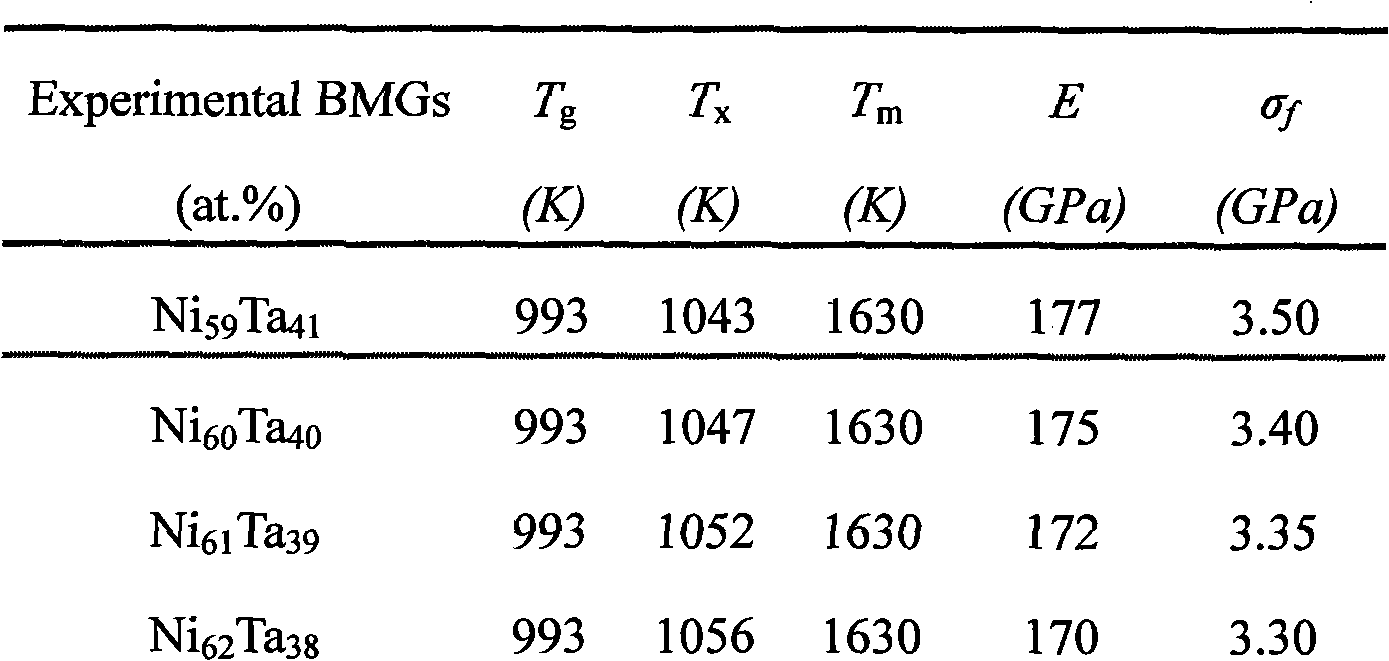

[0030] Example 1 Ni 59 Ta 41 Preparation and performance testing of bulk metallic glasses

[0031] Step 1: Weighing of ingredient ratio

[0032] The composition is designed according to the atomic percentage. In the process of weighing the raw materials, the alloy atomic percentage Ni 59 Ta 41 Converted to weight percent Ni 31.8 Ta 68.2 , weighing the raw materials of pure metal Ni and 99.9% Ta with a purity of 99.99% in proportion, for subsequent use;

[0033] Step 2: Melting of alloy ingot

[0034] Put the mixture of Ni and Ta according to the above-mentioned composition ratio in the water-cooled copper crucible of the electric arc melting furnace, and use the non-consumable arc melting method to melt under the protection of argon gas, and repeat the melting 3 times in this way to obtain a uniform composition. alloy ingot;

[0035] Step 3: Preparation of bulk metallic glass

[0036] The alloy ingot is placed in a quartz tube connected to an induction coil. Under th...

Embodiment 2

[0039] Example 2 Ni 60 Ta 40 Preparation and performance testing of bulk metallic glasses

[0040] Step 1: Weighing of ingredient ratio

[0041] The composition is designed according to the atomic percentage. In the process of weighing the raw materials, the alloy atomic percentage Ni 60 Ta 40 Converted to weight percent Ni 32.7 Ta 67.3 , weighing the raw materials of pure metal Ni and 99.9% Ta with a purity of 99.99% in proportion, for subsequent use;

[0042] Step 2: Alloy ingot melting

[0043] Step 3: Preparation of bulk metallic glass

[0044] Step two and step three are the same as step two and step three in embodiment one;

[0045] Step 4: Bulk Metallic Glass Structure and Performance Test

[0046] X-ray detection and thermal analysis test are the same as embodiment one, and the thermodynamic parameters recorded are respectively T g =993K,T x =1047K,T m =1630K; Young's modulus and breaking strength measured by compression testing machine are respectively: E=...

Embodiment 3

[0047] Example 3 Ni 61 Ta 39 Preparation and performance testing of bulk metallic glasses

[0048] Step 1: Weighing of ingredient ratio

[0049] The composition is designed according to the atomic percentage. In the process of weighing the raw materials, the alloy atomic percentage Ni 61 Ta 39 Converted to weight percent Ni 33.6 Ta 66.4 , weighing the raw materials of pure metal Ni and 99.9% Ta with a purity of 99.99% in proportion, for subsequent use;

[0050] Step 2: Alloy ingot melting

[0051] Step 3: Preparation of bulk metallic glass

[0052] Step two and step three are the same as step two and step three in embodiment one;

[0053] Step 4: Bulk Metallic Glass Structure and Performance Test

[0054] X-ray detection and thermal analysis test are the same as embodiment one, and the thermodynamic parameters recorded are respectively T g =993K,T x =1050K,T m =1630K; Young's modulus and breaking strength measured by compression testing machine are respectively: E=...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical dimension | aaaaa | aaaaa |

| critical dimension | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com