Special sizing agent for chopped strands for strengthening phenolic resin

A technology of chopped strands and phenolic resin, which is applied in the field of production of alkali-free glass chopped fibers, can solve problems such as poor heat resistance, poor composite materials, and discoloration of products, and achieve good production processability, good stability, Effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

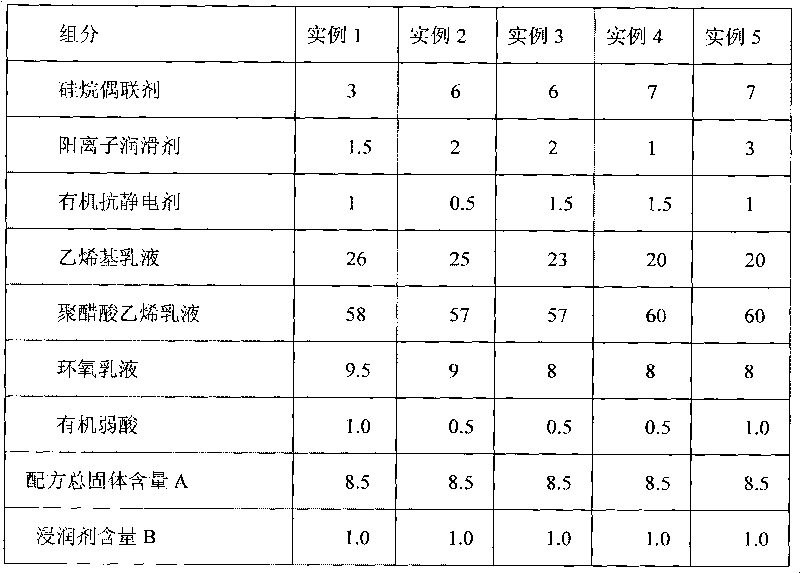

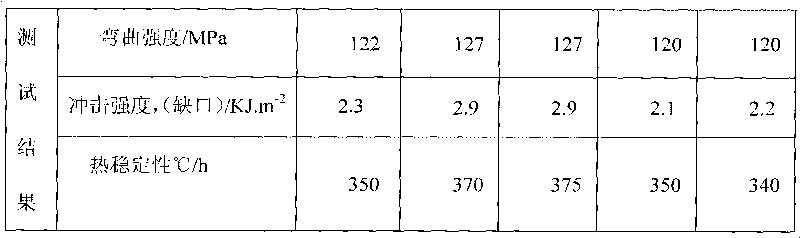

[0031] The technical scheme of the present invention will be further described below with specific examples, but protection scope of the present invention is not limited to this:

[0032] Determination of the embodiment of the present invention formula and description of the experimental method:

[0033] In order to ensure stable production of E-chopped strands, meet the requirements of chopped strands, and improve mechanical properties, we have selected silane coupling agents / cationic lubricants / organic antistatic agents / vinyl emulsions / polyvinyl acetate emulsions / Combination of epoxy emulsion / organic weak acid, this combination can guarantee to improve the mechanical properties of phenolic resin.

[0034] The raw material component among the present invention is selected as follows:

[0035] Silane coupling agent: γ-aminopropyltriethoxysilane (A-1100 from MOMENTIVE)

[0036] Cationic Lubricant: Stearic Acid Amide

[0037] Organic antistatic agent: fatty amine polyoxyethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com