Hot die steel and tempering process thereof

A technology of hot work die steel and process, applied in the field of hot work die steel and its tempering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0022] Prepare hot work die steel raw materials of the present invention as shown in Table 1, and obtain hot work die steel by smelting according to traditional techniques.

[0023] A tempering process for the above-mentioned hot work die steel, comprising the following steps: first tempering at 450°C for 1.5 hours, cooling to room temperature; then tempering at 540°C for 1 to 2 hours, cooling to room temperature; finally tempering at 550°C Temper for 1.5 hours and cool to room temperature.

[0024] Table 1 Units (Wt%)

[0025]

Embodiment 6

[0026] Embodiment 6 impact toughness comparative experiment

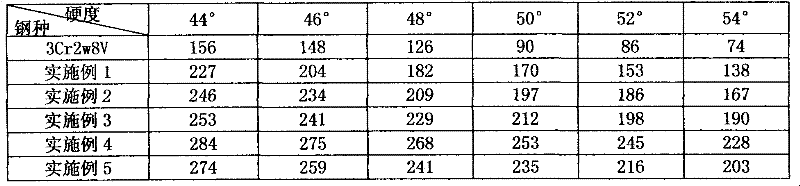

[0027] The average impact toughness comparison experiments at different hardnesses (HRC) were carried out on the hot work die steels of Examples 1-5 and 3Cr2w8V, and the experiments are shown in Table 2 below.

[0028] Table 2 Specimen Specifications 7×10 Unit: (J / cm 2 )

[0029]

[0030] From the comparison of impact toughness, it can be concluded that each composition of the present invention will greatly exceed 3Cr2w8V steel at different hardness (HRC).

Embodiment 7

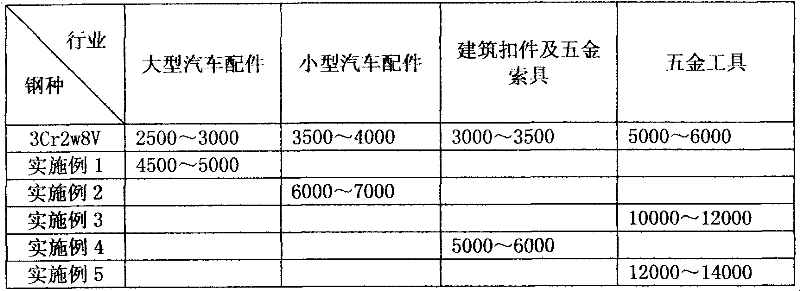

[0031] Embodiment 7 life comparative experiment

[0032] In different industries and different use environments, the life comparison experiments of the hot work die steels of Examples 1 to 5 and the 3Cr2w8V steel dies are performed, and the experiments are shown in Table 3 below.

[0033] Table 3 Unit: (pieces)

[0034]

[0035] Experimental data shows that the service life of the hot work die steel of the present invention is much higher than that of 3Cr2w8V steel in different occasions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com