C/ZrC ceramic matrix composite and preparation method thereof

A composite material and ceramic-based technology, which is applied in the field of ceramic-based composite materials and their preparation, can solve problems such as high requirements, complex processes, and high material brittleness, and achieve the effects of simple equipment requirements, simplified preparation processes, and low preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

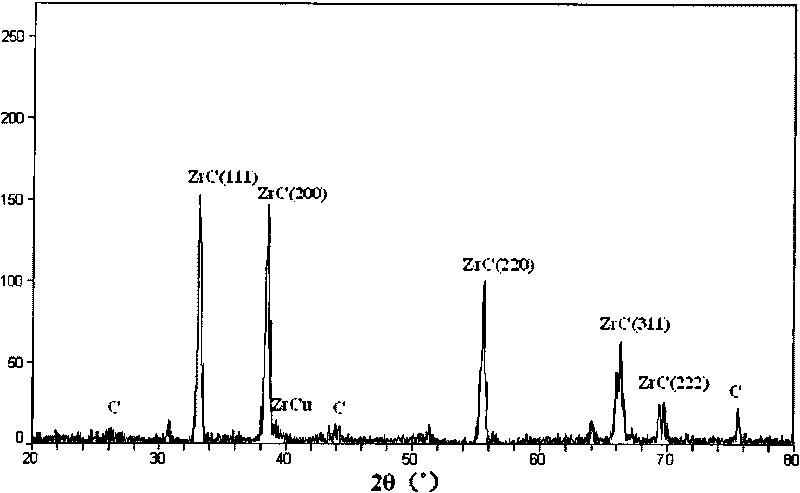

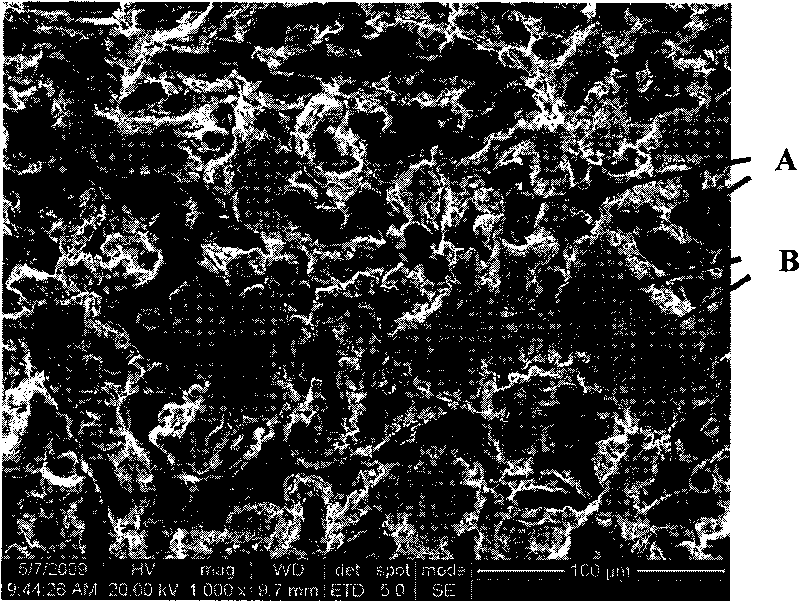

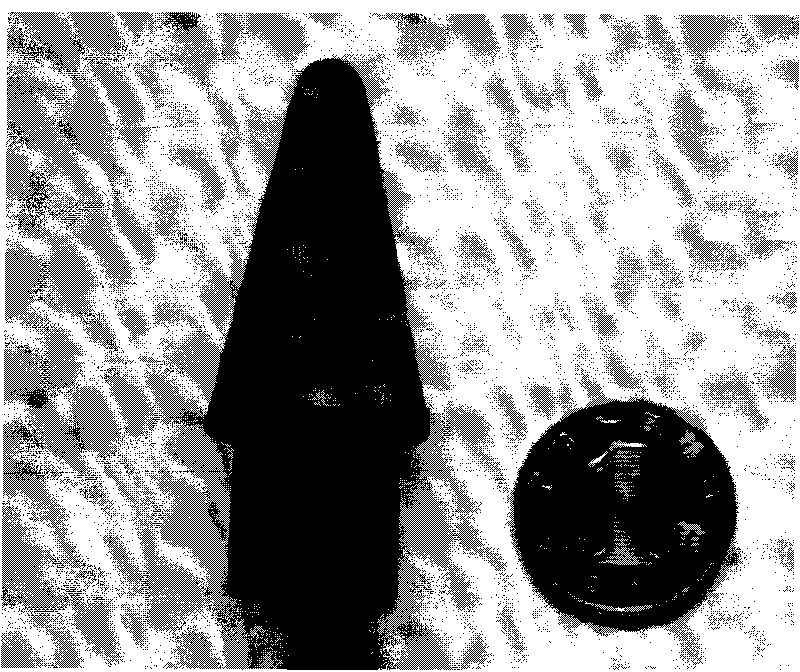

Image

Examples

Embodiment 1

[0018] A C / ZrC ceramic matrix composite material of the present invention, the composite material uses carbon fiber as a reinforcing and toughening phase (the carbon fiber preform adopts a three-dimensional woven structure), and uses ZrC as a matrix. The volume fraction of ZrC in the composite material is 41%, the volume fraction of carbon fiber is 50%, and the porosity is 9%.

[0019] The above-mentioned C / ZrC ceramic matrix composite material is prepared by the following steps:

[0020] 1. Preparation of carbon fiber preforms: Using continuous carbon fibers as raw materials, the carbon fiber preforms are prepared by three-dimensional four-way weaving, and the fiber volume fraction in the carbon fiber preforms is 50%;

[0021] 2. Preparation of C / C composite material: Based on the carbon fiber preform obtained in step 1 of this example, using phenolic resin as raw material, the C / C composite material is obtained by the resin liquid phase impregnation and cracking method. The...

Embodiment 2

[0026] A C / ZrC ceramic matrix composite material of the present invention, the composite material uses carbon fiber as a reinforcing and toughening phase (the carbon fiber preform adopts a needle-punched carbon fiber felt structure), and uses ZrC as a matrix. The volume of ZrC in the composite material The fraction is 63%, the volume fraction of carbon fiber is 30%, and the porosity is 7%.

[0027] The above-mentioned C / ZrC ceramic matrix composite material is prepared by the following steps:

[0028] 1. Preparation of carbon fiber preforms: carbon fiber preforms with felt structure are prepared by needle punching, and the fiber volume fraction in the carbon fiber preforms is 30%;

[0029] 2. Preparation of C / C composite material: Based on the carbon fiber preform obtained in step 1 of this example, chemical vapor deposition combined with resin liquid phase impregnation cracking method (first chemical vapor deposition process is used to make fiber in the carbon fiber preform)....

Embodiment 3

[0034] A C / ZrC ceramic matrix composite material of the present invention, the composite material uses ZrC as a matrix, a needle-punched carbon fiber felt as a reinforcing and toughening phase, the volume fraction of the matrix in the composite material is 52%, and the reinforcement increases. The volume fraction of tough phase in this composite is 40%, and the porosity is 8%.

[0035] The above-mentioned C / ZrC ceramic matrix composite material is prepared by the following steps:

[0036] 1. Preparation of carbon fiber preforms: The carbon fiber preforms are prepared by using the overall carbon felt as the raw material, and the carbon fiber preforms are prepared by the needle punching method, and the fiber volume fraction in the carbon fiber preforms is 40%;

[0037] 2. Preparation of C / C composite material: Based on the carbon fiber preform obtained in step 1 of this example, a C / C composite material is obtained by chemical vapor deposition combined with resin liquid phase im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com