Nano-pore electric sensor

A nanopore and sensor technology, applied in the field of sensors, can solve problems such as integration of nanometer electrodes with single base resolution, and achieve the effect of rapid electronic gene sequencing and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Chemical vapor deposition method prepares and transfers graphene

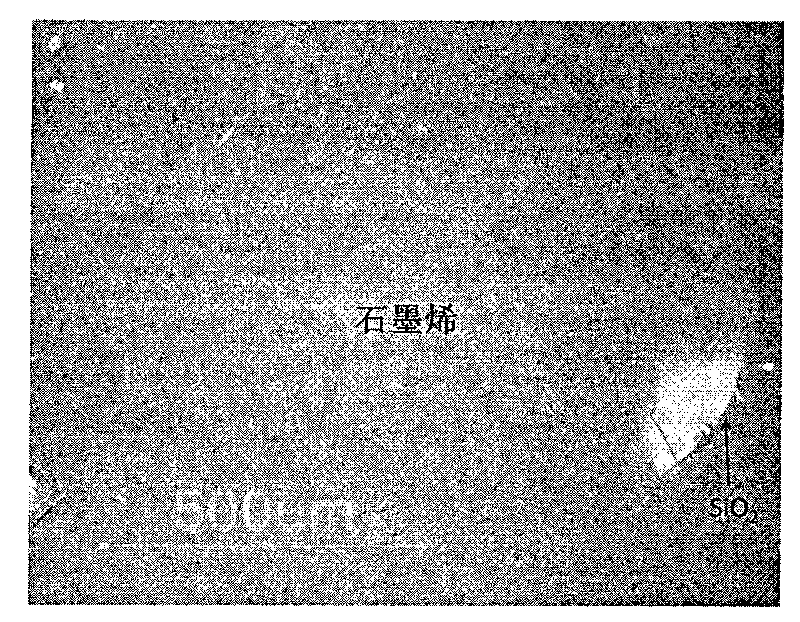

[0022] In SiO 2 (300nm) / Si(500μm) prepared 100nm Cu film, placed in ultra-high vacuum (5.0×10 -9 torr) heat treatment at 950°C for 30 minutes; then, through C 2 h 4 Gas growth for 60 seconds; thereby obtaining graphene on the Cu film. Transfer graphene from Cu to SiO 2 On / Si: spin-coat 500nm Polymethylmethacrylate (PMMA) layer on graphene, place the graphene / Cu that is coated with PMMA in iron nitrate solution and corrode Cu film, thereby obtain PMMA / graphene, then PMMA / graphite ene transfer to SiO 2 / Si on ( image 3 and Figure 4), and finally, use acetone to dissolve PMMA, so that graphene is transferred to SiO 2 / Si on.

[0023] Effect: High-uniform single-layer graphene can be prepared on the surface of metal Cu, and it is easy to transfer graphene to the insulating layer by corroding the Cu catalytic layer.

Embodiment 2

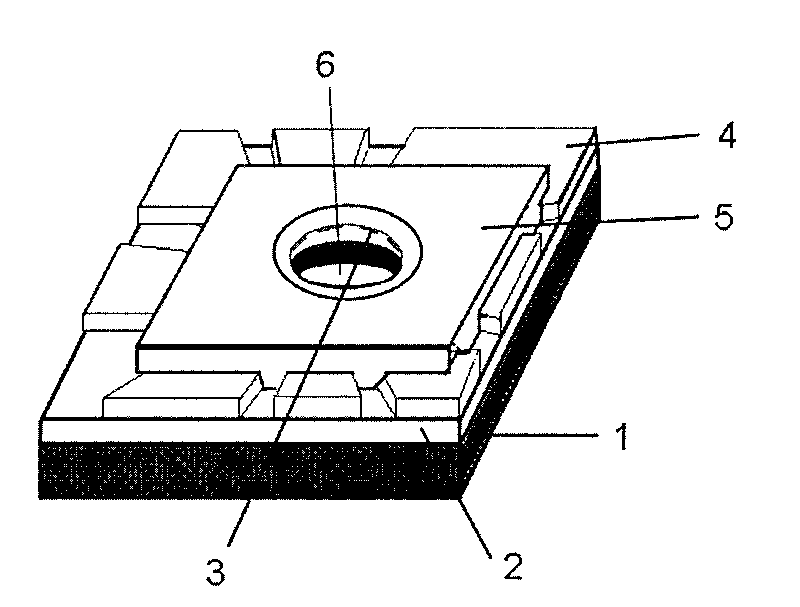

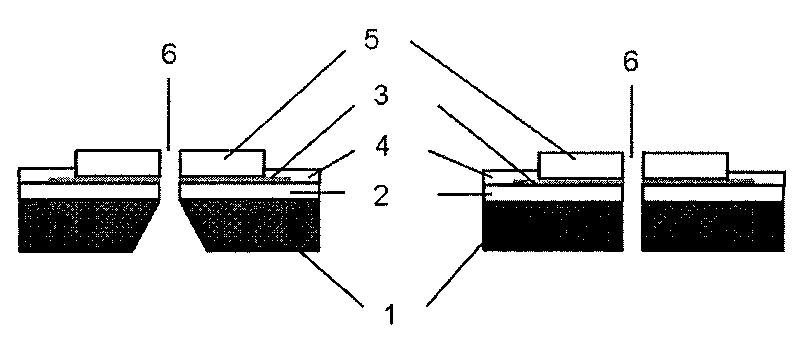

[0025] like Figure 5 Shown: on a 500μm thick monocrystalline silicon substrate 1( Figure 5 a) Preparation of 50nm SiO by upper thermal oxidation 2 Insulation layer 2 ( Figure 5 b); the prepared graphene layer 7 is transferred to SiO 2 Insulation layer 2 ( Figure 5 c); Graphene can be prepared by different methods, such as chemical vapor deposition on metallic Cu, and then transferred onto SiO 2 insulating layer2. Graphene electrode pair 3 patterns were prepared by photolithography and oxygen plasma etching ( Figure 5 d). Among them, since the thickness of the graphene electrode layer is only about 0.35nm, in order to establish effective electrical contact, on the graphene electrode pair 3 patterns, use photolithography and etching technology to prepare Cr(5nm) / Au on the graphene electrode pair. (50nm) electrical contact layer 4 ( Figure 5 e); Then, prepare 70nm Al by atomic layer deposition 2 o 3 and the preparation of 100nm Si by plasma-enhanced chemical vapor...

Embodiment 3

[0027] like Figure 6 Shown: On a 500 μm thick single crystal SiC {0001} substrate 1 in ultra-high vacuum (1.0 × 10 -10 torr) for thermal (950°C-1400°C) surface treatment to become Si-terminated surface or C-terminated surface insulating layer 2 ( Figure 6 a), thus epitaxial growth obtains graphene layer 7 ( Figure 6 b). Graphene electrode pair 3 patterns were prepared by photolithography and oxygen plasma etching ( Figure 6 c). Wherein, since the thickness of the graphene electrode layer is only about 0.7nm, in order to establish an effective electrical contact, photolithography and etching techniques are used to prepare Pd (50nm) electrodes on the graphene electrode pair 3 patterns. Contact layer 4 ( Figure 6 d); Then, prepare 100nm Si by plasma-enhanced chemical vapor deposition 3 N 4 Insulation layer 5( Figure 6 e); Finally, prepare a 3nm nanopore 6 ( Figure 6 f).

[0028] Effect: High-uniform graphene can be prepared on a large scale on an ultra-high vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com