Method for separating and purifying patchouli alcohol

A patchouli alcohol, separation and purification technology, applied in the field of separation and purification of natural active ingredients, to achieve the effect of simple and mature process, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

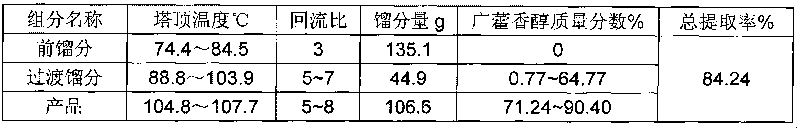

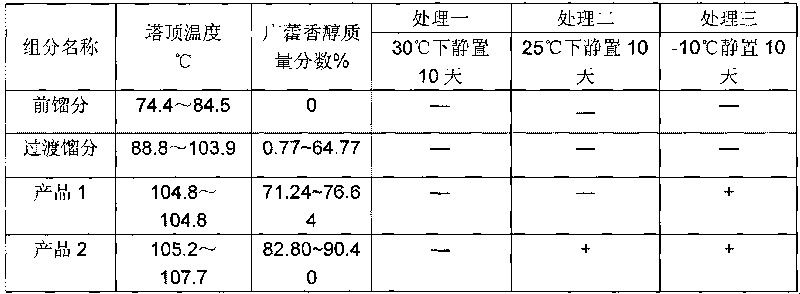

[0024] Experimental Example: Separation and Purification of Patchouli Alcohol in Patchouli Oil by Batch Rectification

[0025] 1. Experimental equipment

[0026] Distillation experimental equipment: using rectification tower inner diameter φ25mm, tower height 1.5m, φ3×3mm stainless steel e-shaped mesh ring packing; AL intelligent temperature control instrument; swing tower head, automatic control of reflux; 2XZ-0.5 vacuum pump; U type differential pressure gauge.

[0027] 2. Experimental method

[0028] The vacuum distillation experiment was carried out under the pressure of 745mmHg. Add patchouli oil 350g, turn on the cooling water switch, after ensuring that the cooling water is normal, turn on the electric heating mantle switch and start heating. The heating current is adjusted to 0.6A. After about 30 minutes, the temperature of the kettle rose to 134.8°C, and the patchouli oil began to boil. After 10 minutes, the temperature of the tower kettle reached 135.1°C, and re...

experiment example 2

[0041] Experimental Example 2 Separation and Purification of Patchouli Alcohol in Patchouli Oil by Vacuum Distillation

[0042] 1. Materials and equipment

[0043] 500mL distillation flask, 100mm thorn-shaped fractionation column, 400mm condenser tube, 500mL temperature-controlled electric heating mantle, connection tube, thermometer 100-300°C, 250mL buffer bottle, 2XZ-1 vacuum pump.

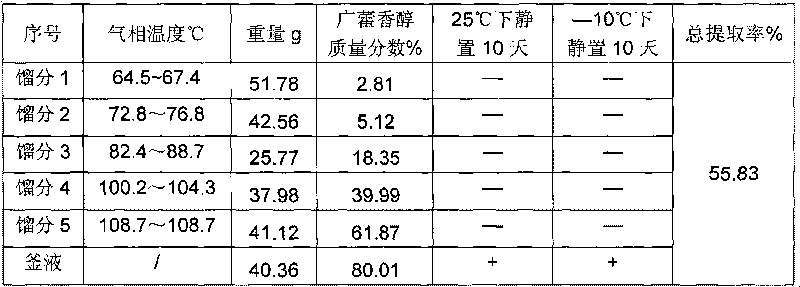

[0044] 2. Methods and Results

[0045] Set up the vacuum distillation device, get patchouli oil 250g, add in the distillation flask, heat, open vacuum 400Pa. When the gas phase temperature reaches 64°C, start discharging, adjust and control the temperature, maintain a uniform temperature gradient in the fractionation column, and control the speed of the distillate at about 2 to 3 seconds / drop, and obtain the component collectors The samples in the sample and the still liquid in the distillation flask were analyzed by gas chromatography, and the extraction rate and mass fraction of patchouli al...

experiment example 3

[0050] Experimental Example Trimolecular Distillation Separation and Purification of Patchouli Alcohol in Patchouli Oil

[0051] 1. Materials and equipment

[0052] Pope WFS wiped film molecular still

[0053] 2. Methods and results

[0054] Put 500g of patchouli oil into the molecular distillation device from the feeder, fill the cold trap with liquid nitrogen to protect the vacuum system, turn on the condensed water at 25°C, and when the required vacuum degree of 0.2Pa is reached, turn on the heat transfer oil system for precise control When the temperature of the evaporating surface is close to the set value, turn on the motor, adjust the scraping film rotor to an appropriate speed, and scrape the material evenly around the cylinder wall. Molecular distillation was carried out at an evaporation temperature of 75°C, a feed rate of 80mL / h, and a film scraping rate of 190r / min, and the sample in the heavy component collector was obtained for gas chromatographic analysis to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com