Method for manufacturing three-dimensional package heat dissipation structure of rigid-flexible joint board

A rigid-flexible board and three-dimensional packaging technology, which is applied to semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve the problems of rising junction temperature of the upper chip 204, affecting life, and not easy to dissipate heat. Achieve low cost, increase heat dissipation path, and effectively dissipate heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

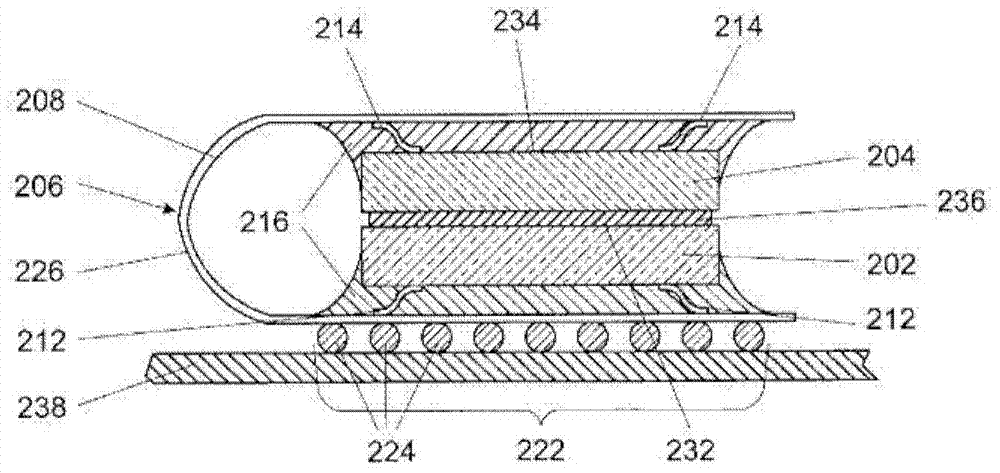

[0033] figure 2 A schematic diagram of the three-dimensional package heat dissipation structure of the rigid-flex board provided by the present invention, the three-dimensional package heat dissipation structure includes:

[0034] a flexible substrate 100;

[0035] A bottom substrate 102 and two rigid substrates 101 pressed together on the flexible substrate 100, wherein the two rigid substrates 101 are symmetrically distributed on both sides of the bottom substrate 102, and a cavity is dug in the two rigid substrates 101, the bottom substrate 102 can use a rigid substrate or a flexible substrate, and a rigid substrate is used in this embodiment;

[0036] The two copper bases 103 are bonded and fixed on the backs of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com