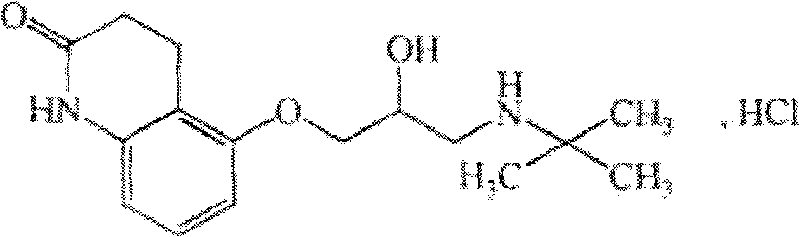

Carteolol hydrochloride pellets, preparation method thereof and preparation thereof

A technology of carteolol hydrochloride pellets and carteolol hydrochloride pellets is applied in the fields of coated pellets, pellet tablets and pellet capsules, and carteolol hydrochloride pellets, and achieves easy quality control, Narrow particle size distribution and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, the preparation of carteolol hydrochloride pellets

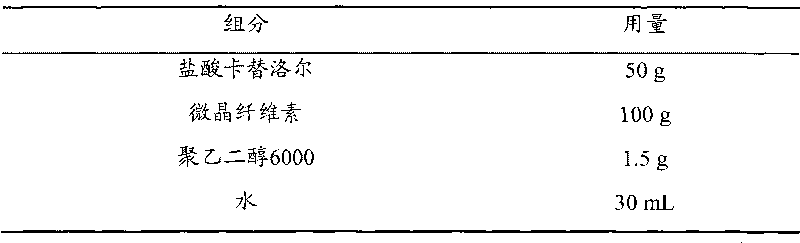

[0030] prescription

[0031]

[0032] method Grind carteolol hydrochloride, microcrystalline cellulose and polyethylene glycol 6000 into fine powders with a fineness above 100 mesh; , mix evenly, add water to make a soft material, put it in an extrusion spheronizer, set the extrusion sieve to 1.0mm, the extrusion speed to 90r / min, the spheronization speed to 480r / min, and the spheronization time to 8min to make micro pellets, dried at 40°C, sieved, and collected pellets with a particle size of 20 to 24 meshes.

[0033] quality The particle size distribution range of the obtained micropills is narrow, and the yield of the micropills with a particle size of 20 to 24 meshes is 95%; 83%.

Embodiment 2

[0034] Embodiment 2, the preparation of carteolol hydrochloride pellets

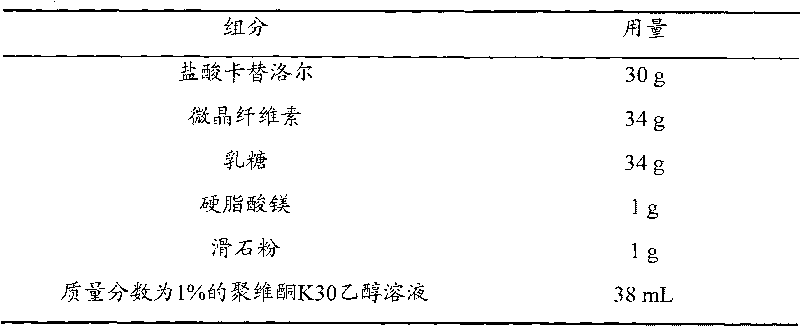

[0035] prescription

[0036]

[0037] method Grind carteolol hydrochloride, microcrystalline cellulose, lactose, magnesium stearate and talc into fine powders with a fineness of more than 100 mesh; take prescribed quantities of carteolol hydrochloride, microcrystalline cellulose and lactose , magnesium stearate and talcum powder, mix evenly, add the povidone K30 ethanol solution that mass fraction is 1% and make soft material, put in extrusion spheronizer, setting extrusion sieve hole is 1.0mm, extrusion speed The spheronization speed is 100r / min, the spheronization speed is 500r / min, and the spheronization time is 6min to make pellets, dry at 35-45°C, sieve, and collect pellets with a particle size of 20-24 meshes.

[0038] quality The particle size distribution range of the obtained micropills is narrow, and the yield of the micropills with a particle size of 20 to 24 meshes is 89%; 81%.

Embodiment 3

[0039] Embodiment 3, the preparation of carteolol hydrochloride pellets

[0040] prescription

[0041]

[0042] method Carteolol hydrochloride, microcrystalline cellulose and lactose were pulverized into fine powders with a fineness of more than 100 mesh respectively; the prescribed amount of carteolol hydrochloride, microcrystalline cellulose and lactose were mixed, and the volume fraction was added to 40% ethanol is made into a soft material, put it in an extrusion spheronizer, set the extrusion sieve to 1.0mm, the extrusion speed to 110r / min, the spheronization speed to 460r / min, and the spheronization time to 5min to make pellets , dried at 45°C, sieved, and collected pellets with a particle size of 20 to 24 meshes.

[0043] quality The particle size distribution range of the obtained micropills is narrow, and the yield of the micropills with a particle size of 20 to 24 meshes is 87%; 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com