Dendriform cationic leather fixing agent and preparation method thereof

A technology of cationic etherifying agent and color-fixing agent, applied in dyeing method, textile and papermaking, fiber processing, etc., can solve the problems of large usage, rough leather surface, low activity, etc., to reduce dosage, increase fastness, small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

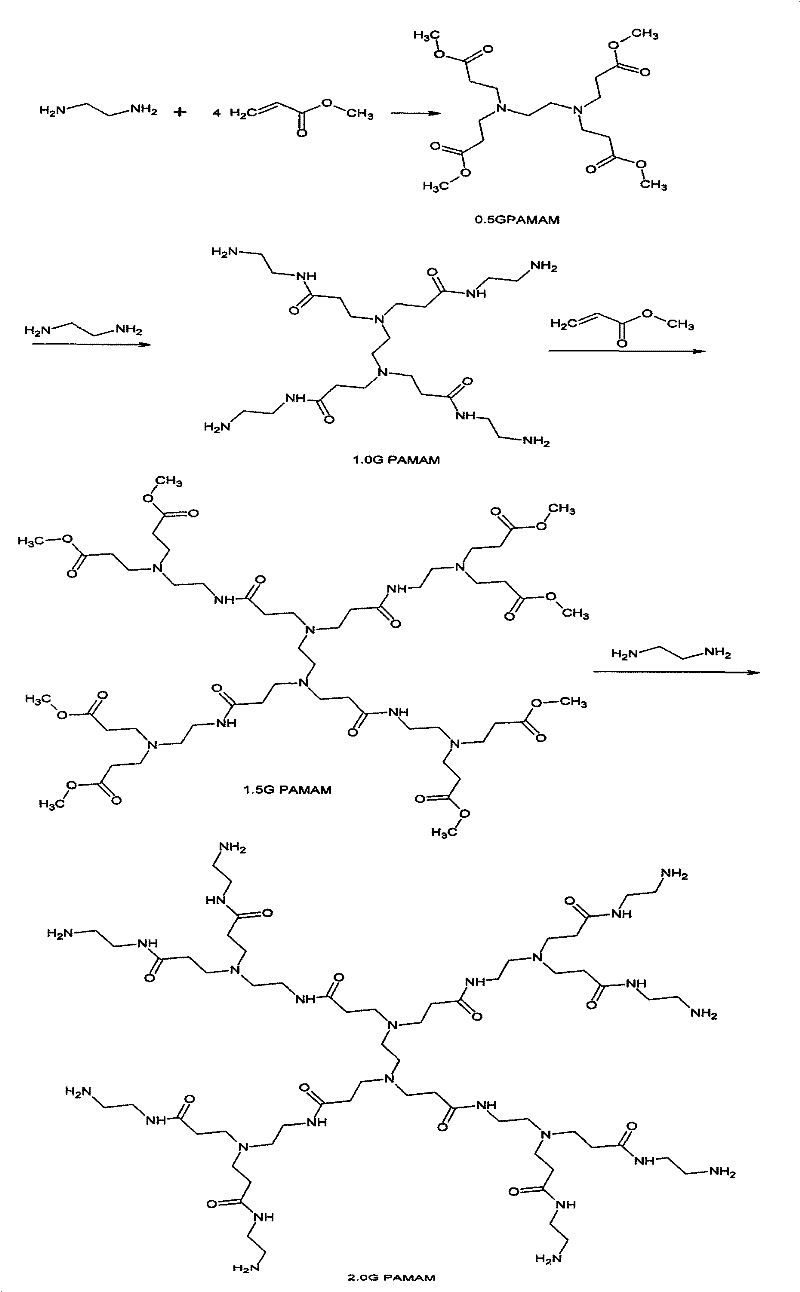

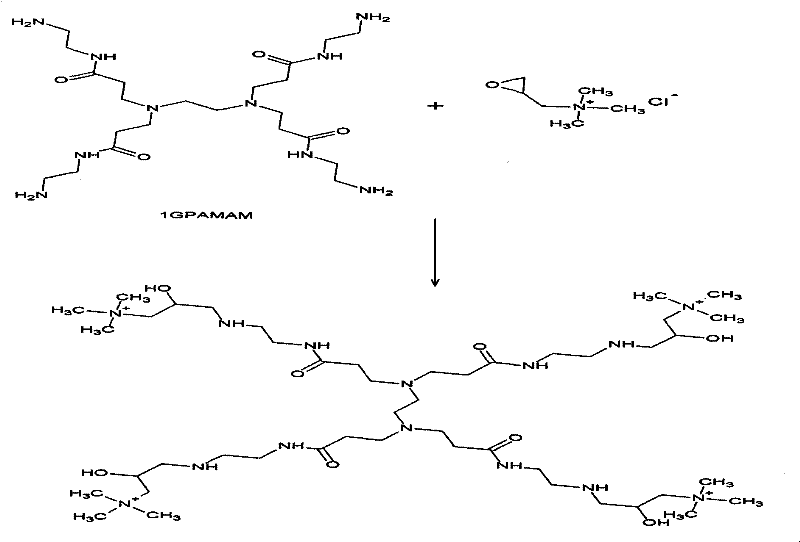

[0037] (1) Synthesis of dendritic polyamidoamines from generation 0.5 to generation 1.0

[0038] Synthesis of 0.5-generation dendritic polyamidoamine: Mix methyl acrylate and ethylenediamine at a molar ratio of 1:6 in an ice-water bath, add 30% of the total volume of the reaction system to anhydrous methanol as a solvent, and stir the reaction at room temperature After 10 hours, vacuumize at 30°C, and rotate distillation at a vacuum degree of 0.08MPa for 1.5 hours to remove the solvent and excess methyl acrylate to obtain 0.5 generation dendritic polyamide-amine;

[0039]Synthesis of 1.0 generation dendritic polyamidoamine: mix 0.5 generation dendritic polyamidoamine and ethylenediamine in an ice-water bath at a molar ratio of 1:24, add anhydrous methanol with 20% total volume of the reaction system As a solvent, after stirring and reacting at room temperature for 20 h, vacuumize at 80° C., and under a vacuum of 0.02 MPa, add entrainer toluene and anhydrous methanol (m (toluen...

Embodiment 2

[0043] (1) Synthesis of dendritic polyamidoamines from generation 0.5 to generation 1.0

[0044] Synthesis of 0.5-generation dendritic polyamidoamine: Mix ethyl acrylate and ethylenediamine at a molar ratio of 1:4 in an ice-water bath, add absolute ethanol with a total volume of 20% of the reaction system as a solvent, and stir at room temperature After reacting for 8 hours, evacuate at 40°C, and perform rotary distillation at a vacuum of 0.07 MPa for 1 hour to remove the solvent and excess ethyl acrylate to obtain 0.5 generation dendritic polyamide-amine;

[0045] Synthesis of 1.0-generation dendritic polyamidoamine: Mix 0.5-generation dendritic polyamidoamine and ethylenediamine in an ice-water bath at a molar ratio of 1:12, add 10% absolute ethanol to the total volume of the reaction system As a solvent, after stirring and reacting at room temperature for 16 hours, vacuumize at 80°C, and at a vacuum of 0.07 MPa, add an entrainer n-butanol with 2% of the total mass of the re...

Embodiment 3

[0049] (1) Synthesis of 0.5-2.0 generation dendritic polyamide-amine

[0050] Synthesis of 0.5-generation dendritic polyamidoamine: Mix butyl acrylate and ethylenediamine at a molar ratio of 1:7 in an ice-water bath, add anhydrous methanol with a total volume of 15% of the reaction system as a solvent, and stir at room temperature After reacting for 14 hours, evacuate at 50°C, and perform rotary distillation at a vacuum of 0.08 MPa for 1.5 hours to remove the solvent and excess butyl acrylate to obtain a 0.5 generation dendritic polyamide-amine;

[0051] Synthesis of the 1.0th generation dendritic polyamidoamine: mix the 0.5th generation dendritic polyamidoamine and ethylenediamine in an ice-water bath at a molar ratio of 1:16, add 20% of the total volume of the reaction system to anhydrous methanol As a solvent, after stirring and reacting at room temperature for 24 hours, vacuumize at 70°C, and at a vacuum of 0.08 MPa, add an entrainer n-butanol with 2.5% of the total mass o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com