Solid oxide fuel cell and preparation method thereof

A solid oxide, fuel cell technology, applied in the field of electrochemistry, can solve the problem of high ionic conductivity electrode reaction kinetics catalysis ability, easy to produce second equal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

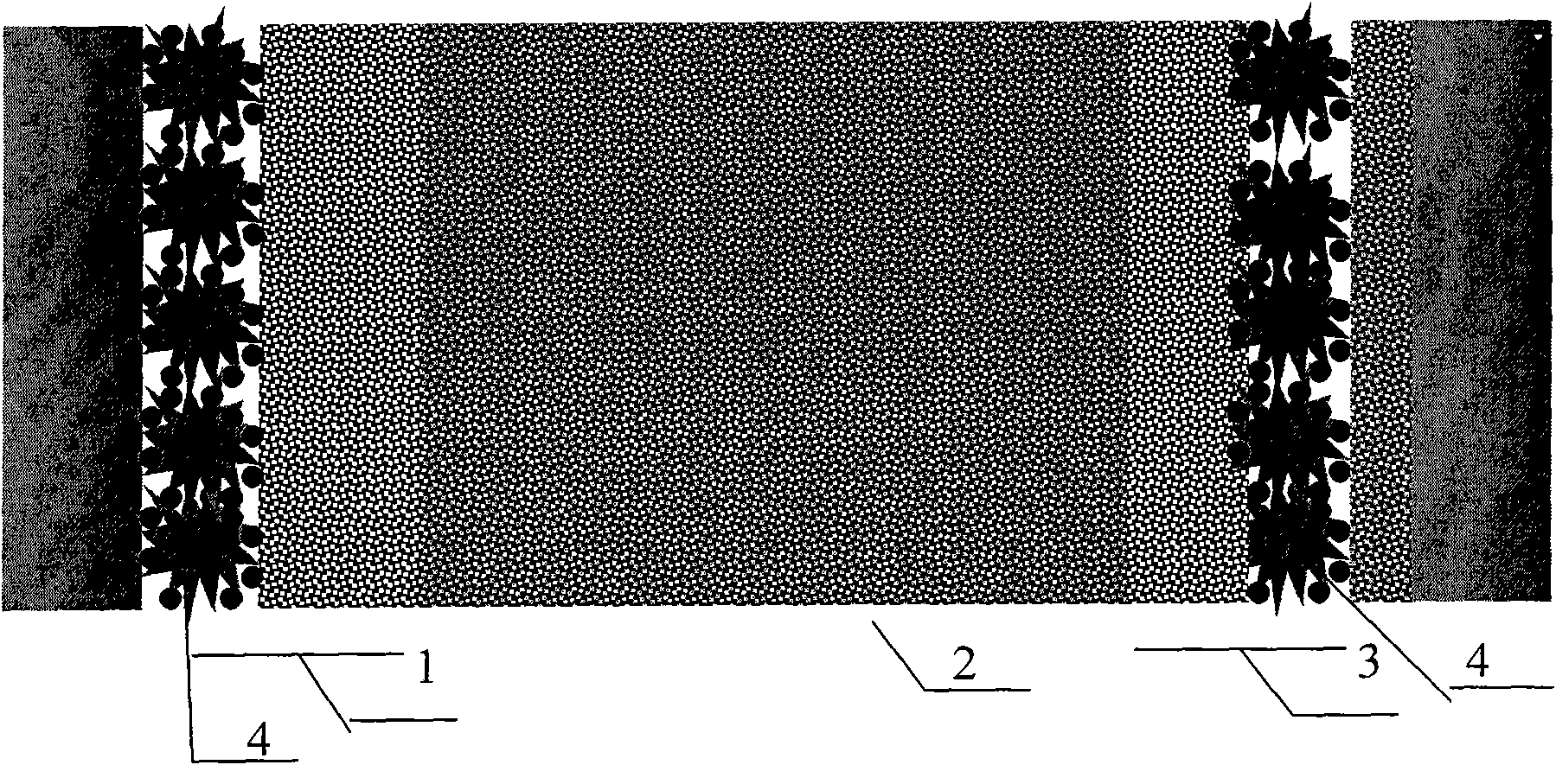

[0056] Fabrication of solid oxide fuel cells

[0057] 1) Ce 0.8 SM 0.2 o 1.9 Preparation of Electrolyte Powder

[0058] By preparing the solution of the nitrate of the metal ion according to the stoichiometric ratio (Ce:Sm mole is 4:1), and then adding a certain amount of glycine (NH 2 -CH 2 -COOH) makes the amount of glycine and nitrate ions in the solution satisfy the molar ratio of 1:2. The prepared solution is evaporated to dryness by heating until it spontaneously ignites to generate oxide powder, and is calcined at 600°C for 2 hours to remove possible residual carbon impurities to form a cubic crystal phase of Ce 0.8 SM 0.2 o 1.9 Powder.

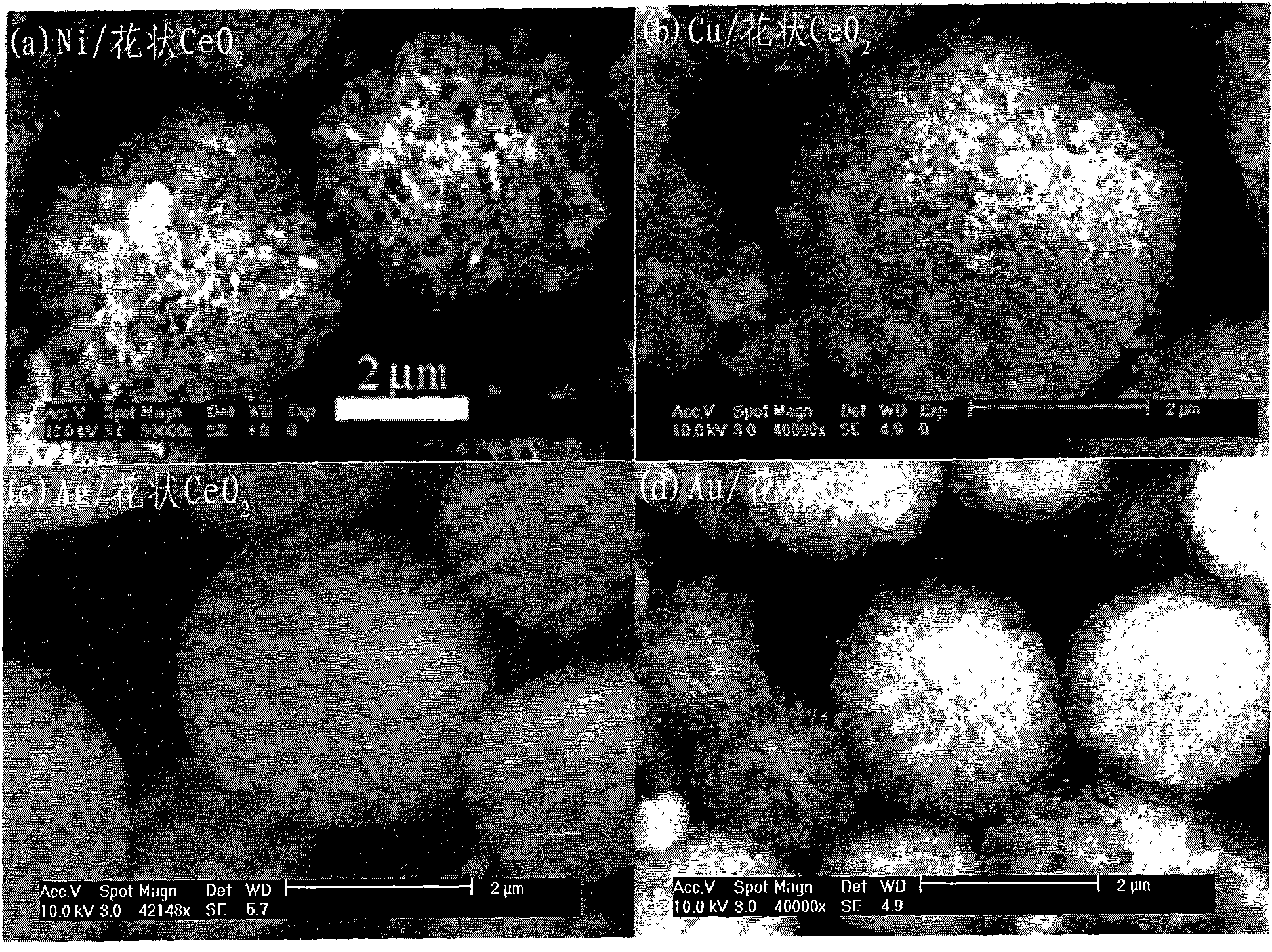

[0059] 2) Flower-shaped nano-CeO 2 preparation of

[0060] By dissolving 0.005 mole of metal ion Ce nitrate, 0.01 mole of glucose, and 0.015 mole of acrylamide in 80 milliliters of deionized water, adding 3.2 milliliters of 25% by weight ammonia water under stirring to form a gel, and continuing to stir for 5 After 1 hour, tra...

Embodiment 2

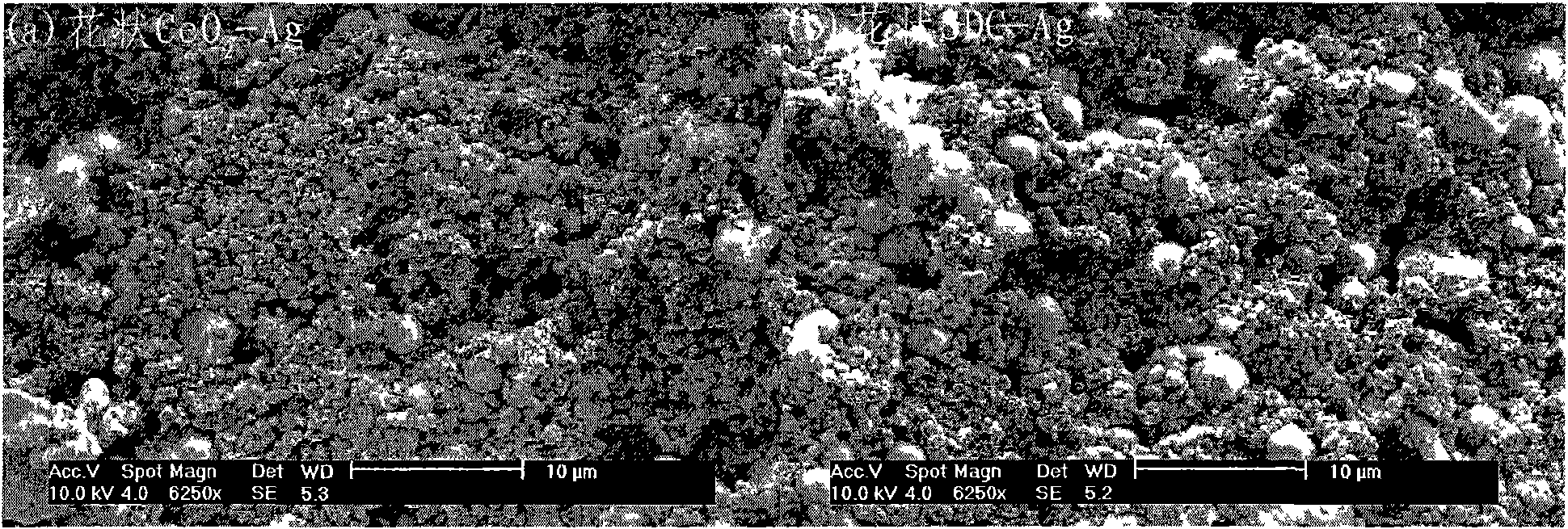

[0066] 10% Sm-doped flower-like cerium-based solid oxide fuel cells

[0067] The preparation and test conditions of the battery are similar to those in Example 1, except that the flower-shaped nano-CeO 2 During preparation, the nitrate of Sm is also added to the mixed solution composed of nitrate of Ce, glucose and acrylamide, and the metering of adding Sm satisfies the following relationship: the molar ratio of Ce to Sm is 9:1, and the total amount of metal ions is kept No change, still 0.005mol. The molecular formula of the cerium-based material to obtain the anode and cathode is Ce 0.9 SM 0.1 o 1.95 .

[0068] When using pure H 2 As fuel, under the test condition of 600°C, the maximum output power density of the battery is about 55mW / cm 2 , the resistance of the full battery is about 2.5Ω.cm 2 . Compared with Example 1, the Sm-doped flower-like material has higher oxygen ion conductivity, which improves the performance of the battery.

Embodiment 3

[0070] 20% Sm-doped flower-like cerium-based material solid oxide fuel cell

[0071] The preparation and test conditions of the battery are similar to those in Example 2, except that the doping ratio of the flower-shaped cerium-based material Sm is 20%. When using pure H 2 As a fuel, under the test condition of 600°C, the maximum output power density of the battery is about 59mW / cm 2 , the resistance of the full battery is about 2.8Ω.cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com