Preparation method of anticorrosive film for metal surface

A technology of metal surface and corrosion film, which is applied to the device and coating of the surface coating liquid, can solve the problems of damage to the mechanical properties of the metal, hidden dangers in the anti-corrosion process, difficult to control the etching process, etc., and achieve good anti-corrosion performance. , The effect of strong adhesion and high protection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

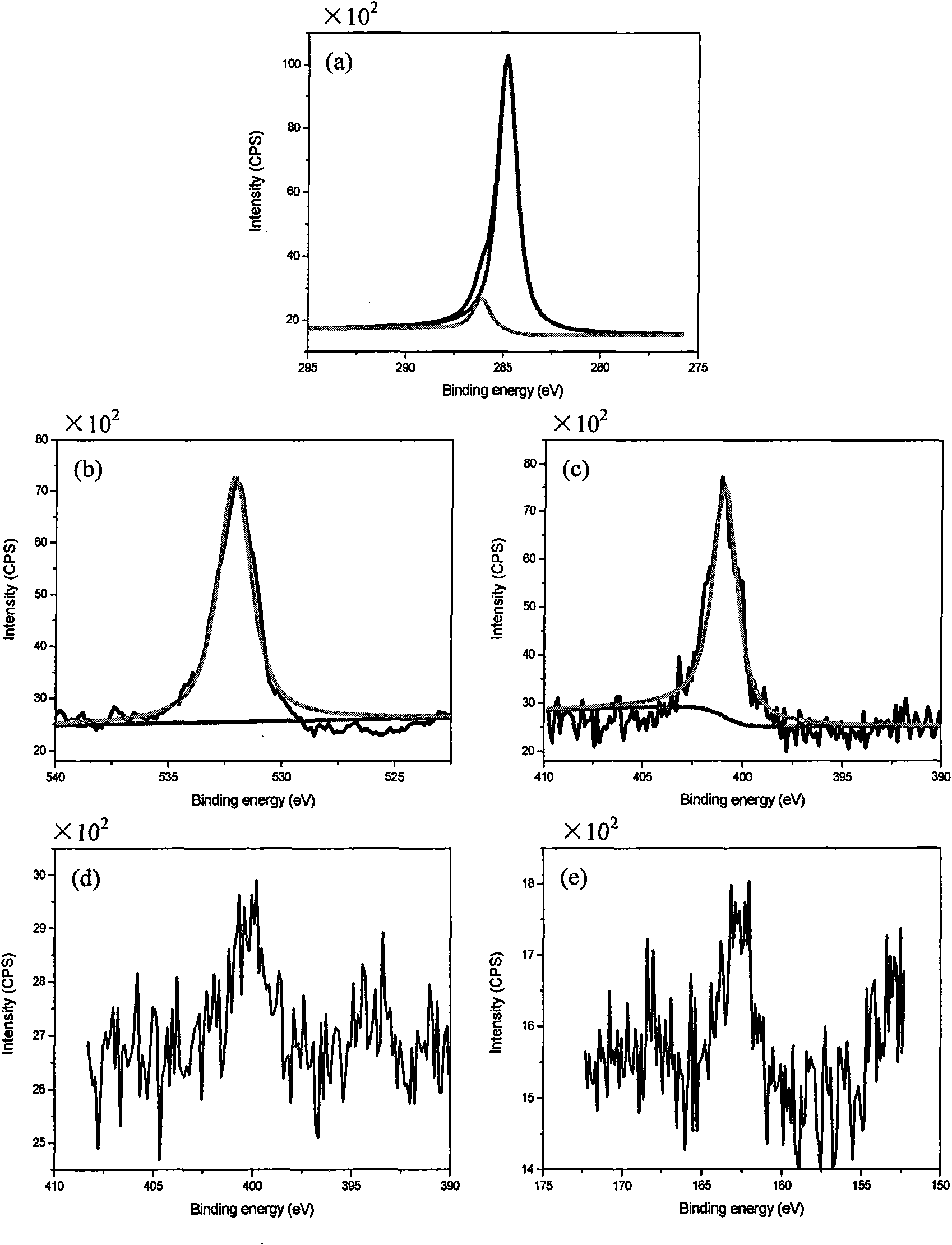

[0016] First prepare 10ml of tris(hydroxymethyl)aminomethane hydrochloride (Tris-HCl) aqueous solution with a concentration of 10 mmol / L, adjust the pH to 8.5 with NaOH, and then put DA into the above aqueous solution at a ratio of 2g / L , stirred for 30 minutes, then immersed the polished copper substrate vertically, took it out after 24 hours of contact, rinsed with deionized water, formed a polyDA film layer on the surface of the copper substrate, dried it with nitrogen, and put it into the nitrogen bubbling concentration. 10 mmol / L of 20ml n-dodecanethiol in dichloromethane solution, 25°C water bath, take out after 24h, wash with dichloromethane, and dry with nitrogen, thus forming an anti-corrosion film on the surface of the copper electrode. Such as figure 1 As shown, the polyDA film layer contains carbon, nitrogen, and oxygen elements, and the peaks of carbon elements are at 284.7eV and 286.1eV, which correspond to C-C / C-H and C-N / C-O bonds respectively. This is mainly b...

Embodiment 2

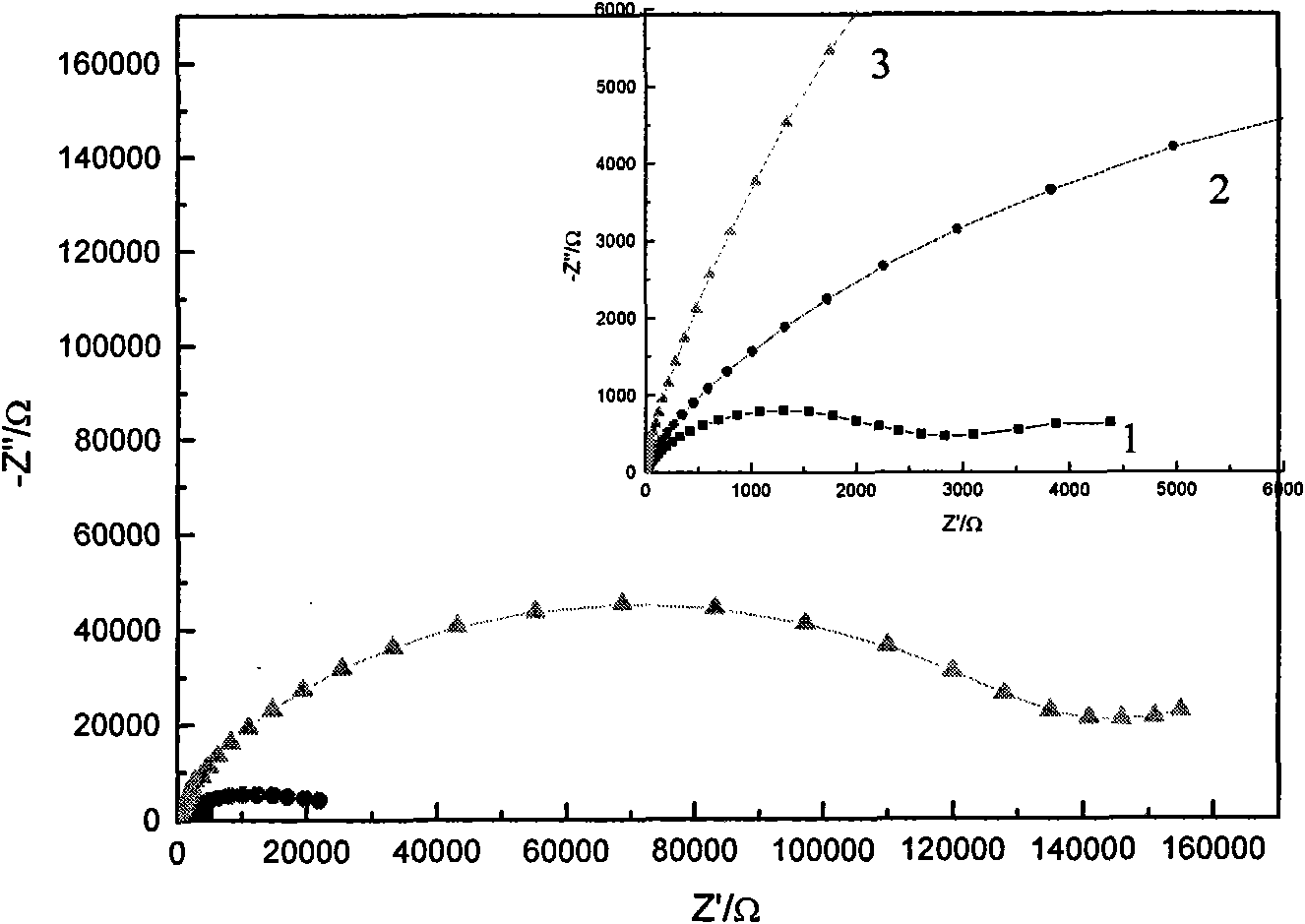

[0023] First configure the concentration of 5 mmol / L phosphate (Na 2 HPO 4 or KH 2 PO 4 ) aqueous solution 10ml, adjust the pH to 9 with NaOH, then put DA into the above aqueous solution at a ratio of 0.2g / L, stir for 20min, then immerse the polished 304 stainless steel substrate vertically, take it out after contacting for 60h, and use deionized water Rinse, dry with nitrogen, put into 20ml of 11-mercapto-1-undecanoic acid (MUA) dichloromethane solution with a concentration of 1 mmol / L bubbled by nitrogen, take it out after 48 hours in a water bath at 20°C, and use di Washing with methyl chloride and drying with nitrogen gas formed an anti-corrosion film on the surface of the 304 stainless steel electrode. Figure 4 The AC impedance diagram (Nyquist diagram) of DA and MUA-treated and untreated 304 stainless steel electrodes respectively immersed in sterilized seawater, curve 1 in the figure corresponds to the blank 304 stainless steel substrate, curve 2 corresponds to the ...

Embodiment 3

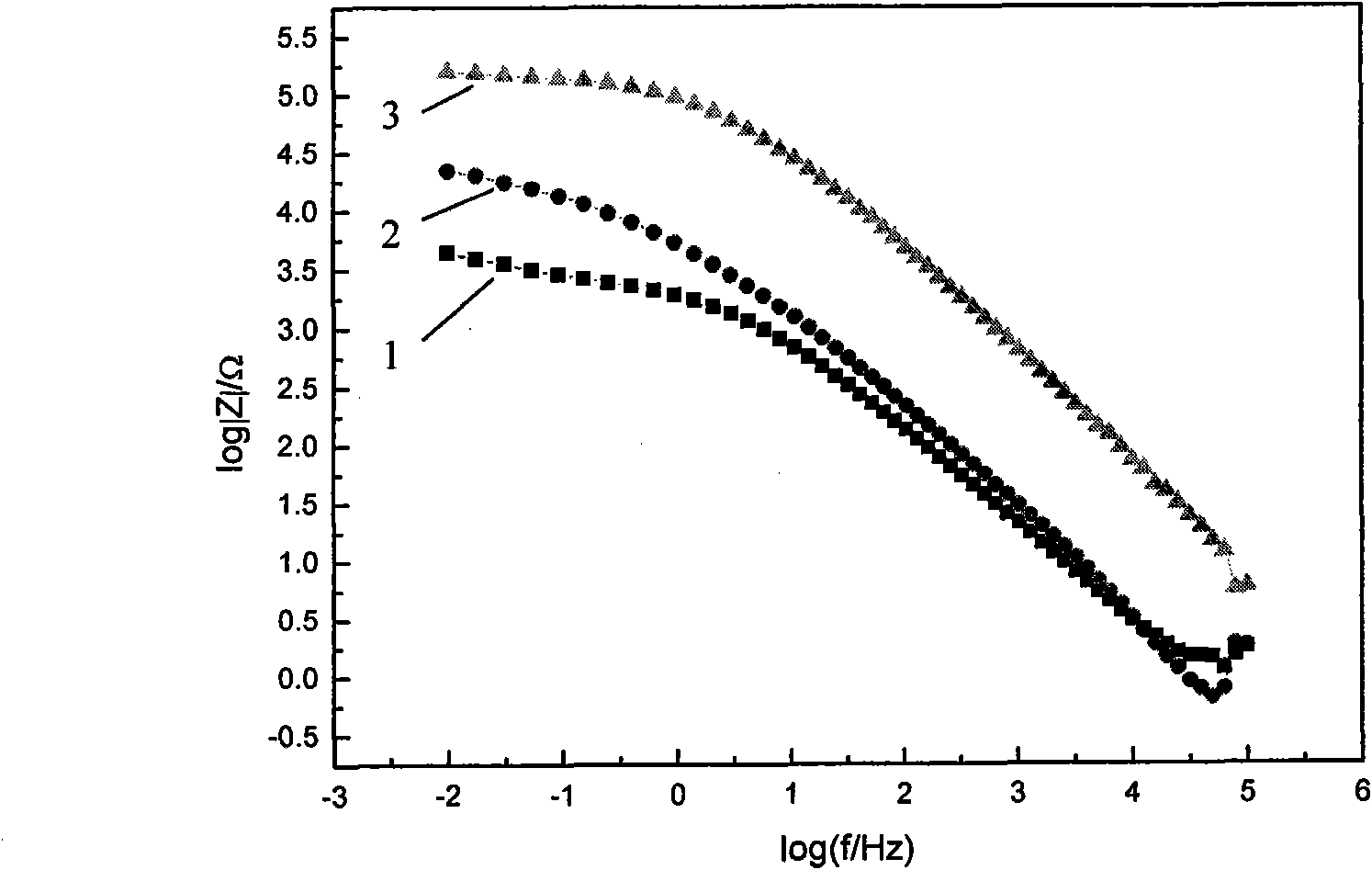

[0025] First prepare 10 ml of an aqueous solution of tris (hydroxymethyl) aminomethane hydrochloride (Tris-HCl) with a concentration of 10 mmol / L, adjust the pH to 8 with NaOH, and then put DA into the above aqueous solution at a ratio of 1 g / L , stirred for 40 minutes, then immersed the polished copper-nickel alloy substrate vertically, took it out after 48 hours of contact, washed it with deionized water, dried it with nitrogen gas, and put it into 20 ml of MUA with a concentration of 2 mmol / L bubbled by nitrogen gas. Dichloromethane solution, 30 ° C water bath, take it out after 24 hours, wash with dichloromethane, and dry with nitrogen, thus forming an anti-corrosion film on the surface of the copper-nickel alloy electrode. Figure 5The polarization curves of DA and MUA-treated and untreated copper-nickel alloy electrodes respectively immersed in sterilized seawater, curve 1 in the figure corresponds to the blank copper-nickel alloy substrate, curve 2 corresponds to the pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com