Flex-rigid integrated circuit (IC) package substrate and manufacturing method thereof

A technology for encapsulating carrier boards and printed circuits, which is applied in the fields of circuits, semiconductor/solid-state device manufacturing, and electrical components. It can solve problems such as low efficiency, product yield, and thick thickness, and achieve thin thickness, noise control, and product quality. The effect of increasing the rate requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

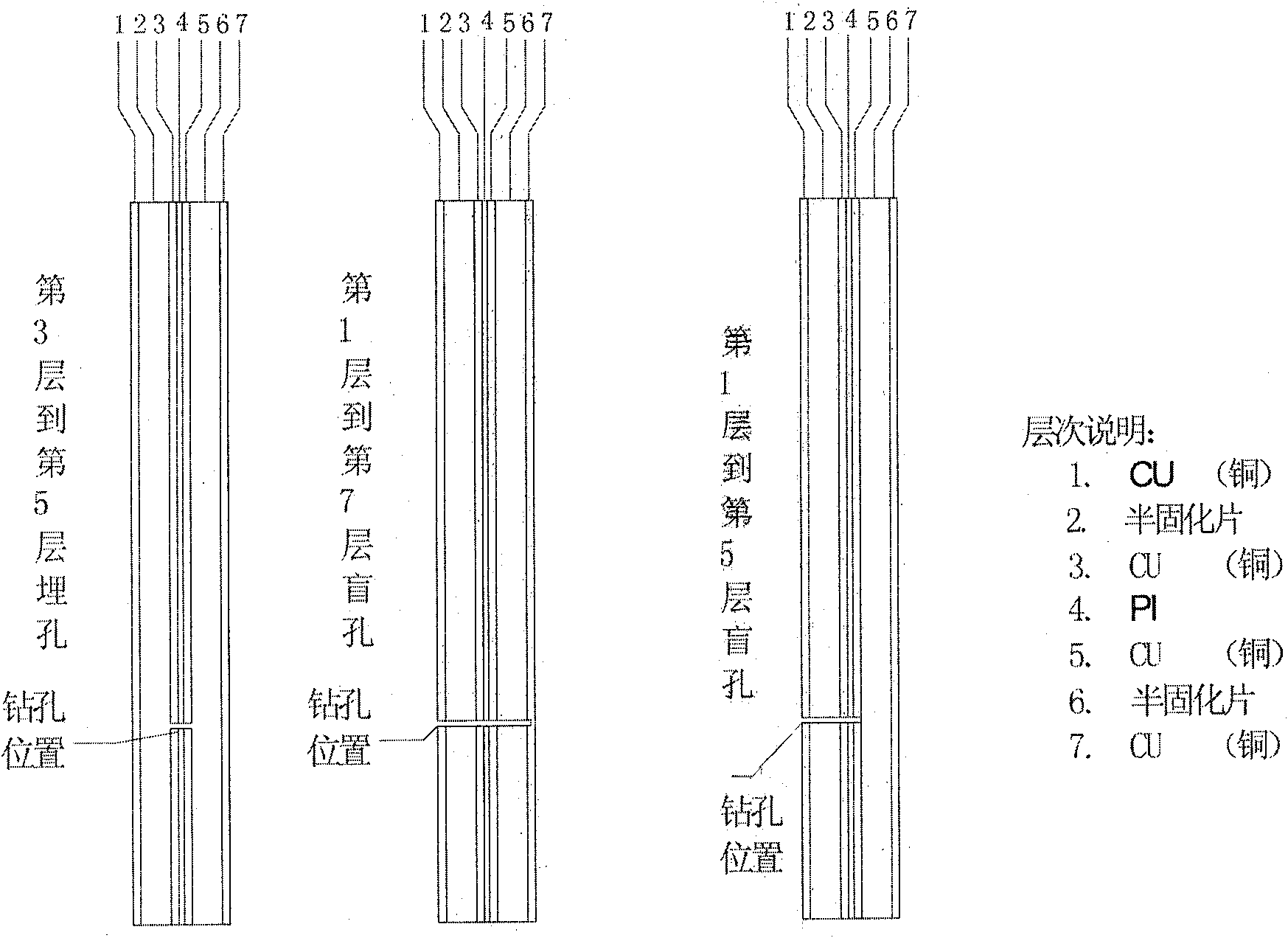

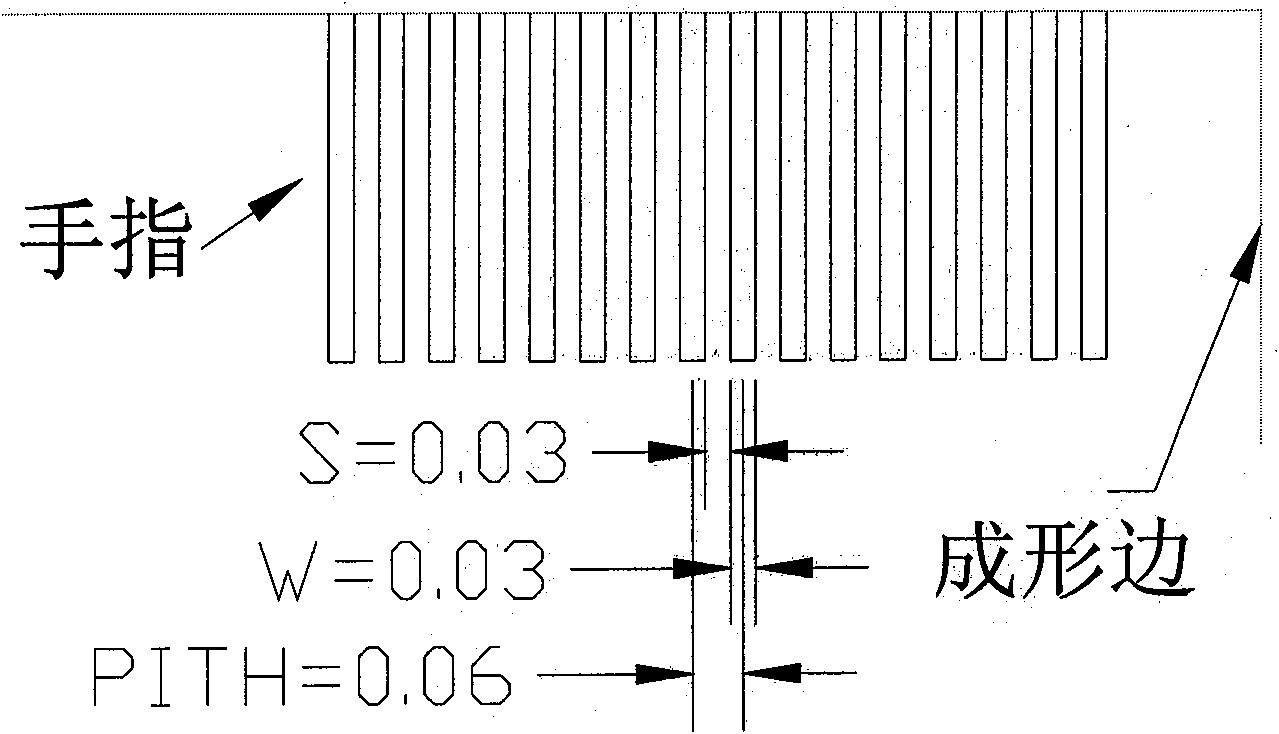

[0015] The invention relates to a rigid-flexible printed circuit (IC) packaging carrier and its manufacturing method. In order to improve the product quality and product performance of the multilayer printed circuit packaging carrier, the invention adopts a high Tg non-flowing PP sheet and Pure copper foil material, using Wire bonding surface treatment technology and automatic alignment and parallel exposure technology, makes the minimum line width / line spacing of the substrate reach 30 microns / 30 microns, the pitch reaches 60 microns, and the thickness of the 4-layer rigid-flex carrier board ≤240 microns, and the thickness tolerance is controlled at ±5 microns. The present invention has adopted ultraviolet and CO 2 The combination of laser and copper foil etching technology effectively avoids the need to rely on controlling the uniformity of product thickness to ensure the drilling accuracy of blind holes, making the 1-3 layer and The yield rate of 1-4 layers of blind buried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com