Method for preparing Co3O4 nano material by Co2O3 powder

A technology for preparing nanomaterials and powders, which is applied in the direction of nanotechnology, nanotechnology, and nanostructure manufacturing. It can solve problems such as complex reaction routes, high raw material costs, and large environmental pollution, and achieve reduced process costs, low raw material costs, and environmental protection. The effect of less pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

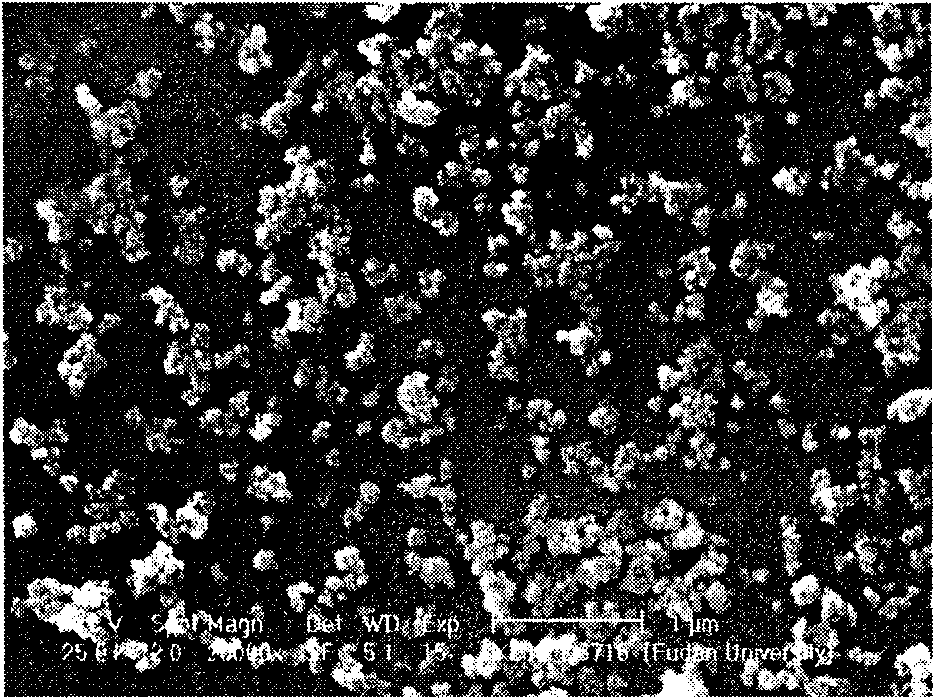

[0030] 0.5mmol of Co 2 o 3 , 1g of glucose and 16ml of deionized water are mixed evenly and put into the reaction kettle, placed in a thermostat and heated at a constant temperature of 120°C for 6h, cooled, separated, and dried to prepare Co 3 o 4 Nanoparticles, analyzed by scanning electron microscopy, show that what is obtained is a non-uniform spherical aggregate composed of particles with a particle size of about 20 nanometers.

Embodiment 2

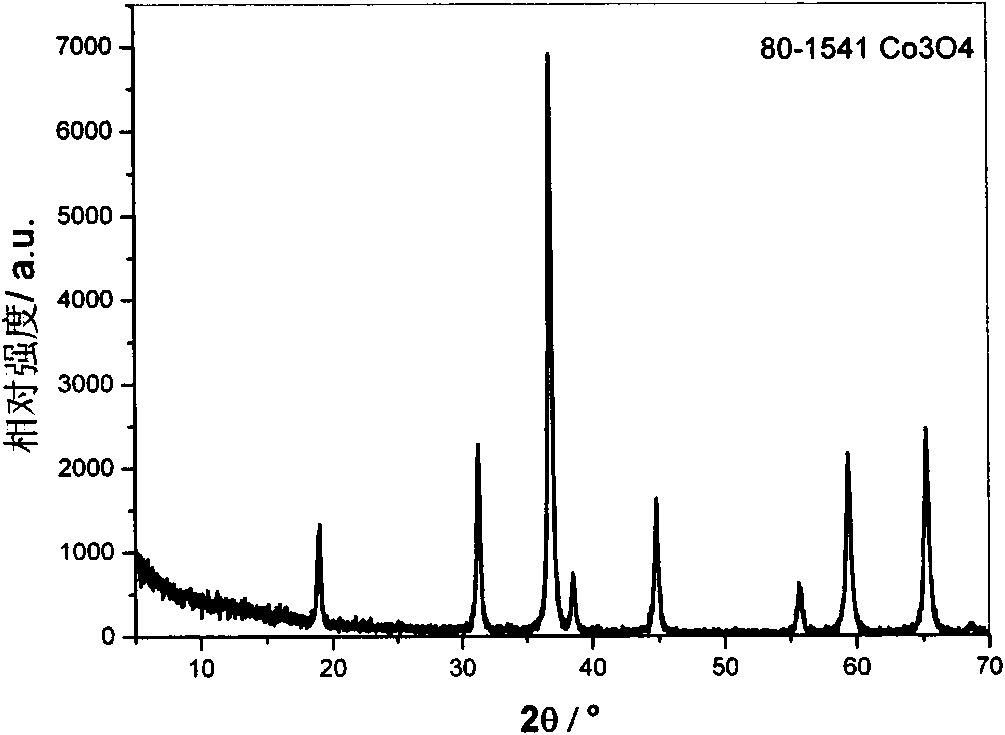

[0032] 1mmol of Co 2 o 3 , 8ml of absolute ethanol and 8ml of deionized water are mixed evenly and put into the reaction kettle, placed in a thermostat and heated at a constant temperature of 160°C for 6h, after cooling, separation and drying, Co 3 o 4 Nanoparticles, XRD spectrum see Figure 1 , the figure shows that the peak position of the XRD spectrum of the obtained sample is consistent with that of Co in the international standard spectrum library. 3 o 4 The materials are exactly the same, and the average diameter of the nanoparticles is 30nm by calculation.

Embodiment 3

[0034] 1mmol of Co 2 o 3 , 1.6ml of absolute ethanol and 14.4ml of deionized water are mixed evenly and put into the reaction kettle, placed in a constant temperature box and heated at a constant temperature of 160°C for 24h, after cooling, separation and drying, Co 3 o 4 nanoparticles. According to the analysis of transmission electron microscope, the product is Co with an average particle size of about 40nm. 3 o 4 Nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com