Method for dissolving and extracting cellulose in bagasse

A sugarcane bagasse and cellulose technology, applied in fiber raw material processing, textile and papermaking, etc., can solve problems such as environmental pollution, increase processes, etc., and achieve the effect of expanding the scope of use, facilitating centrifugal separation, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

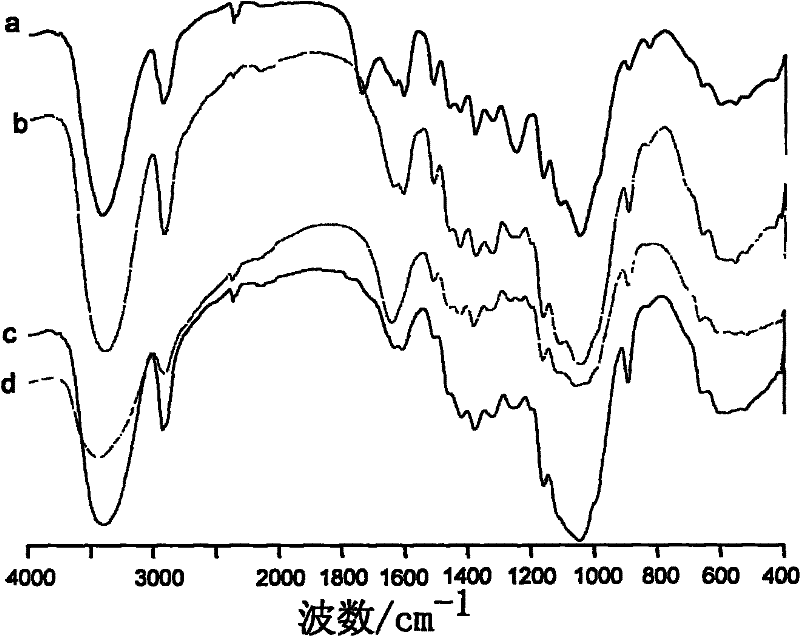

[0023] (1) Pass 80 mesh sieves after bagasse is pulverized (as untreated bagasse, measure its infrared spectrogram and see figure 1 Curve a), soak in water for 2 hours, filter, activate with 1% sodium hydroxide solution by mass percentage for 10 hours, rinse with deionized water to pH 7, filter, and vacuum dry at 60°C for 8 hours to obtain pretreated bagasse (as the bagasse after activation, measure its infrared spectrogram and see figure 1 curve b);

[0024] (2) Add 4.5 g of ionic liquid 1-butyl-3-methylimidazolium chloride salt to 0.5 g of the pretreated bagasse obtained in step (1), heat the temperature to 80 ° C, keep warm for 3 minutes, and add 0.11mol pyridine; Under 80 ℃, carry out dissolving reaction 90min, adopt the rotating speed centrifugation of 4000r / min 8min, obtain cellulose solution; Measure the dissolving rate of bagasse to be 48% (determine the infrared spectrogram of undissolved bagasse residue see figure 1 curve d);

[0025] (3) Add the cellulose solutio...

Embodiment 2

[0028] (1) Bagasse is crushed and passed through an 80-mesh sieve, soaked in water for 1 hour, filtered, activated with 20% sodium hydroxide solution for 5 hours, rinsed with deionized water to pH 7, filtered, and vacuum-dried at 100°C After 12h, obtain the bagasse of pretreatment;

[0029] (2) Add 19 g of ionic liquid 1-butyl-3-methylimidazolium chloride salt to 1 g of the pretreated bagasse obtained in step (1), heat the temperature to 80 ° C, keep warm for 2 min, and add 0.33 mol of it while stirring Pyridine pyridine; the dissolution reaction was carried out at 70°C for 30 minutes, and centrifuged at a speed of 2000r / min for 10 minutes to obtain a cellulose solution; the dissolution rate of bagasse was measured to be 40%;

[0030] (3) Add the cellulose solution obtained in step (2) into deionized water, stir for 120 minutes, and then filter to obtain a filter residue; wash the filter residue twice with deionized water, and dry at 100° C. for 6 hours to obtain regenerated c...

Embodiment 3

[0032] (1) Bagasse is crushed and passed through a 60-mesh sieve, soaked in water for 4 hours, filtered, activated with 15% sodium hydroxide solution for 24 hours, rinsed with deionized water to pH 7, filtered, and vacuum-dried at 80°C After 10h, the pretreated bagasse was obtained;

[0033] (2) Add 10 g of ionic liquid 1-butyl-3-methylimidazolium chloride salt to 1 g of the pretreated bagasse obtained in step (1), heat the temperature to 80° C., and keep it warm for 4 minutes, then add 0.23 mol of it while stirring Pyridine; the dissolution reaction was carried out at 100°C for 240 minutes, and centrifuged at a speed of 3000r / min for 5 minutes to obtain a cellulose solution; the dissolution rate of bagasse was measured to be 44%;

[0034] (3) Add the cellulose solution obtained in step (2) into deionized water, stir for 100 min, and then filter to obtain a filter residue; wash the filter residue with deionized water for 5 times, and dry at 80°C for 10 hours to obtain regenera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com