Ink for inkjet printing zirconia insulating layer and preparation method thereof

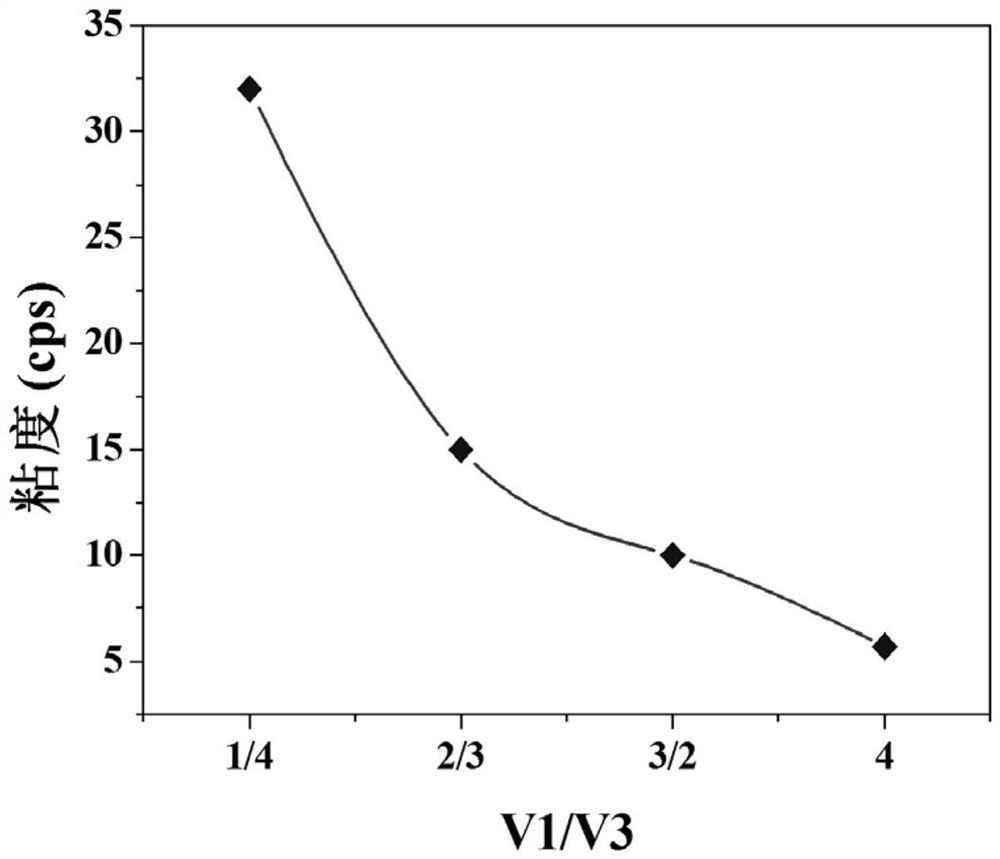

A technology of inkjet printing and zirconia, which is applied in ink, applications, household appliances, etc., can solve the problems of poor inkjet state and pattern forming effect, low solvent viscosity, low overall viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Drug and reagent preparation

[0039] Raw material preparation for solution preparation: zirconium oxychloride octahydrate, analytically pure, content ≥99.0%, Shanghai Runjie Chemical Reagent Co., Ltd.; ethylene glycol methyl ether, analytically pure, content ≥99.0%, Tianjin Fuyu Fine Chemical Co., Ltd. ; Polyethylene glycol 200, chemically pure, molecular weight 190-210, Shanghai Runjie Chemical Reagent Co., Ltd.; ethylene glycol, analytically pure, content ≥ 99.0%, Shanghai Runjie Chemical Reagent Co., Ltd.

[0040] 2. Base and container cleaning

[0041] Finger bottle cleaning: unscrew the bottle cap of the finger bottle to be washed, sink it into a large beaker filled with isopropanol, and put the bottle cap together. It should be noted that the bottle must be completely filled with isopropanol, and no Bubbles, then ultrasonic (53kHz) vibration for 15min, then deionized water and the same ultrasonic (53kHz) vibration for 15min. Care should be taken to avoid con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com