Graft-modified macromolecular filter membrane for water treatment and method for preparing same

A polymer filter membrane and polymer membrane technology are applied in the field of graft-modified polymer filter membrane for water treatment and its preparation, which can solve the problem of blocking surface pores, changing the surface morphology of the membrane, and decreasing the water flux of the membrane. problem, to achieve the effect of high water flux, improved membrane performance, and high rejection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

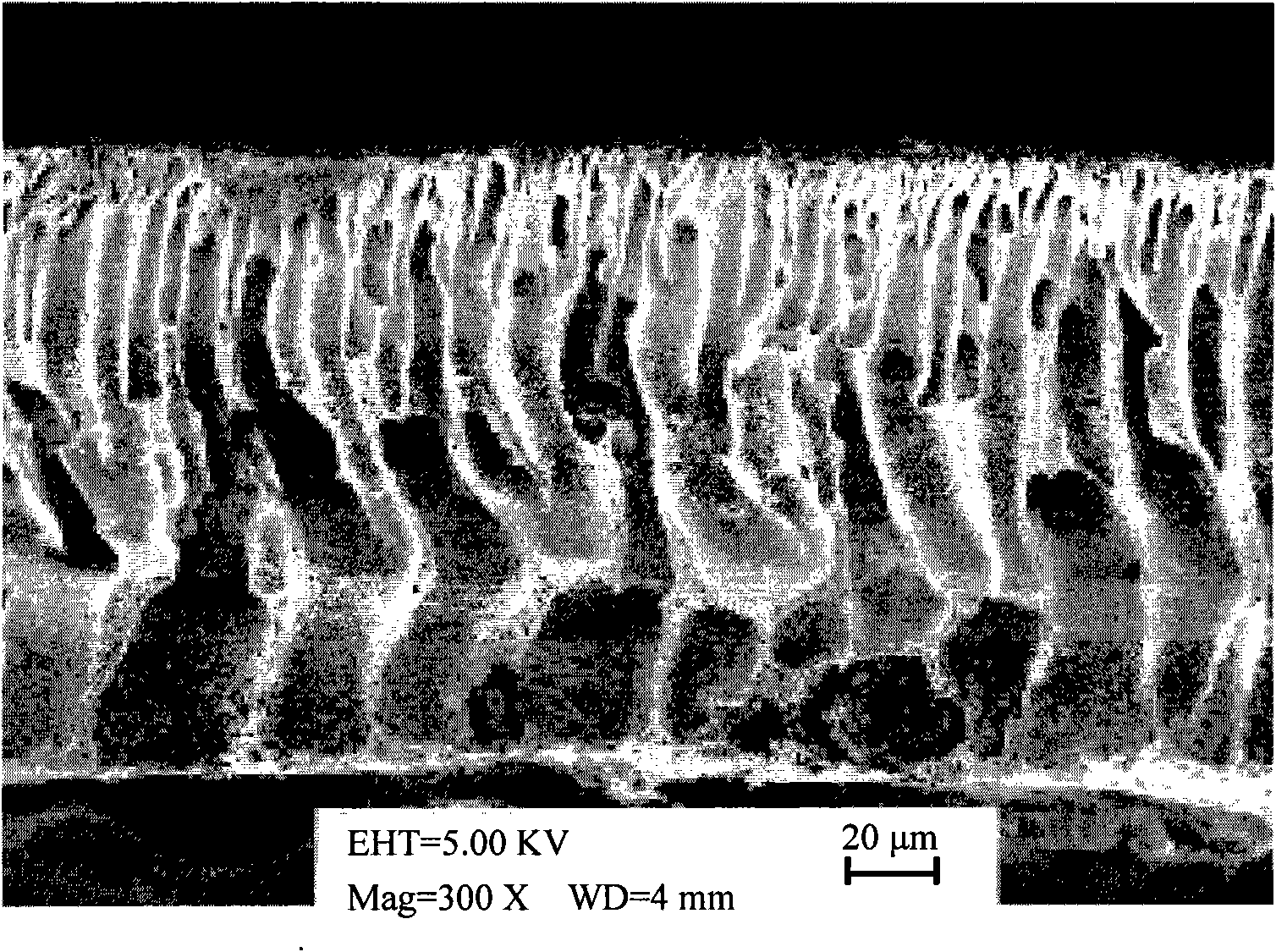

Image

Examples

Embodiment 1

[0020] Embodiment 1 permanent anti-pollution flat sheet microfiltration membrane (membrane 1)

[0021] The polyethersulfone PES powder is irradiated to 20kGy with gamma rays generated by a cobalt source under the protection of nitrogen, and then the irradiated PES powder is placed in an aqueous solution containing 30% acrylic acid AAc and 30% acrylamide AAm , under the protection of nitrogen, the temperature was raised to 60 ° C for 2 hours, and the modified polyethersulfone (PES-g-PAAc) powder with a grafting rate of 25% of polyacrylic acid grafted and the polyacrylic acid grafted with a grafting rate of 25% were respectively obtained. Modified polyethersulfone (PES-g-PAAm) powder grafted with acrylamide. Weigh two kinds of modified polyethersulfone powders according to the molar ratio of AAc and AAm structural units as 1 to 1, dissolve them in N-methylpyrrolidone (NMP) together, and prepare the modified polymer with a weight ratio of 25%. Casting solution, followed by addin...

Embodiment 2

[0028] Embodiment 2 permanent anti-pollution flat sheet microfiltration membrane (membrane 3)

[0029] The polysulfone PSf powder was irradiated to 20kGy by using gamma rays generated by a cobalt source under the protection of nitrogen, and then the irradiated PSf powder was respectively placed in 1% maleic anhydride MAH and 1% 2-vinylpyridine In the aqueous solution of 2-VP, under the protection of nitrogen, the temperature was raised to 60 ° C for 1 hour to react, and the modified polysulfone (PSf-g-PMAH) powder and grafted polymaleic anhydride grafted with a graft rate of 1% were respectively obtained. Modified polysulfone (PSf-g-P2VP) powder grafted with poly-2-vinylpyridine with a branch rate of 1%. Weigh two kinds of modified polysulfone powders according to the molar ratio of MAH to 2-VP structural unit of 1:2, dissolve them together in N-methylpyrrolidone (NMP), and prepare the modified high polymer with a weight ratio of 5%. The casting solution was then added with 0...

Embodiment 3

[0036] Embodiment 3 permanent anti-pollution tubular microfiltration membrane (membrane 5)

[0037] The polyethersulfone PES powder is irradiated to 20kGy with gamma rays generated by a cobalt source under the protection of nitrogen, and then the irradiated PES powder is respectively placed in an aqueous solution containing 50% acrylic acid AAc and 50% acrylamide AAm , under the protection of nitrogen, the temperature was raised to 60 ° C for 5 hours, and the modified polyethersulfone (PES-g-PAAc) powder with a grafting rate of 50% of polyacrylic acid grafted and the polyacrylic acid grafted with a grafting rate of 50% were respectively obtained. Modified polyethersulfone (PES-g-PAAm) powder grafted with acrylamide. Weigh two kinds of modified polyethersulfone powders according to the molar ratio of AAc and AAm structural units as 1:1, dissolve them together in N,N-dimethylacetamide, and prepare the modified polymer with a weight ratio of 40%. The casting solution, followed b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com