Preparation method of hydrophobic starch food packaging film

A starch food and packaging film technology, applied in textiles and papermaking, liquid repellent fibers, fiber treatment, etc., can solve the problems of poor water blocking performance of starch films, and achieve the improvement of water blocking performance, film performance, and reaction. mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In view of this, the present invention proposes a method for preparing a hydrophobic starch food packaging film. The preparation method of described hydrophobic starch food packaging film comprises the following steps:

[0039] Step S10, dissolving starch in an aqueous dimethyl sulfoxide solution to form a spinning solution.

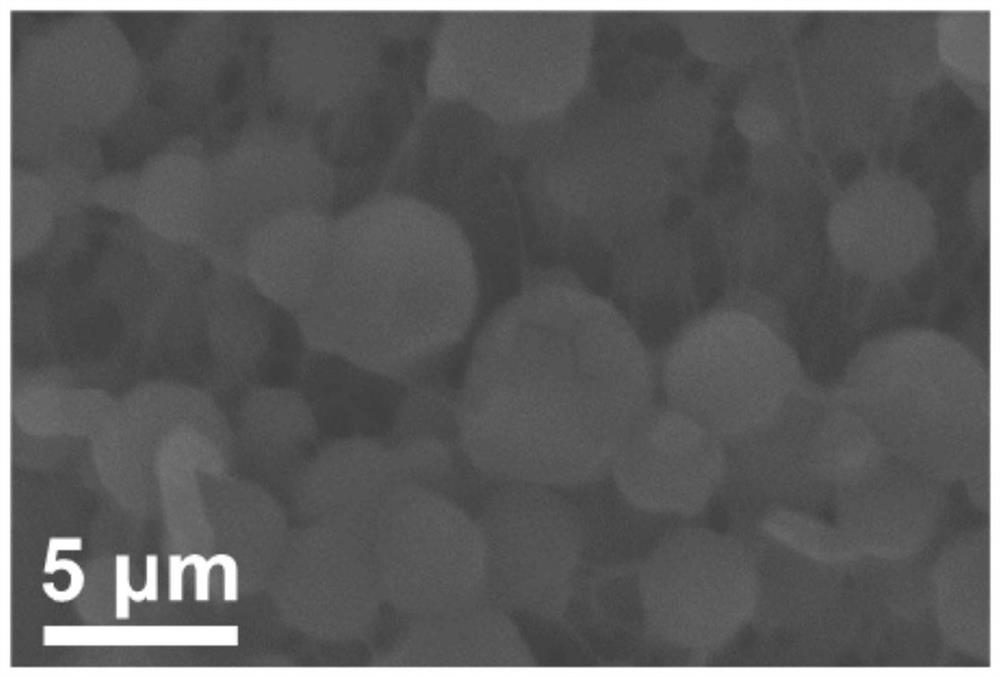

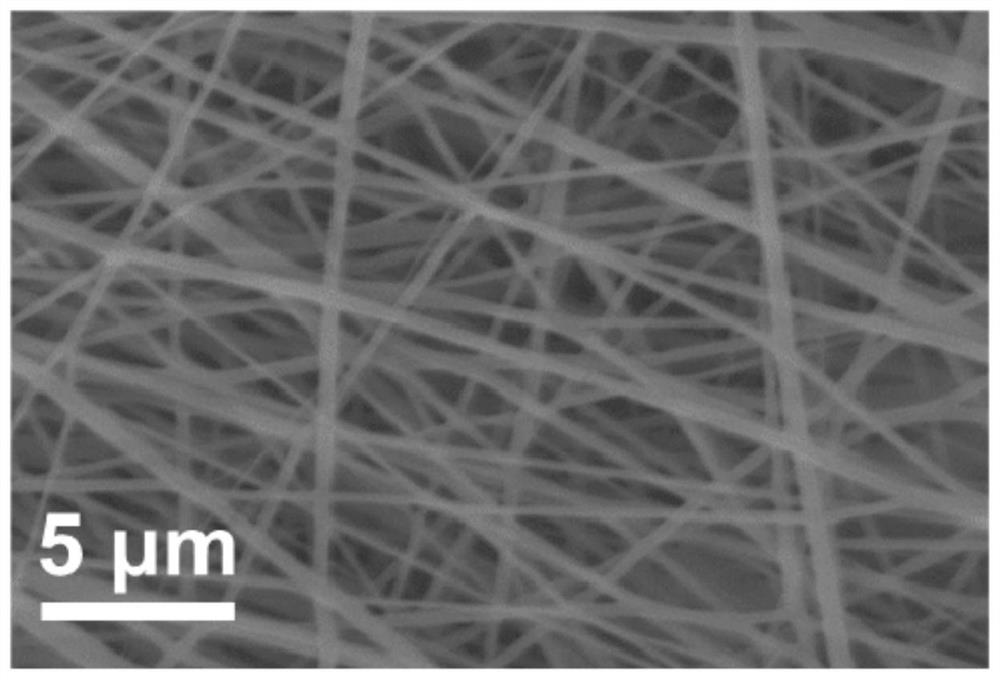

[0040] In this embodiment, starch is added to an aqueous solution of dimethyl sulfoxide, stirred to dissolve to form a solution, and then left to defoam to obtain a spinning solution. Specifically, in order to ensure that the starch is fully dissolved, in this embodiment, the starch is added to the aqueous solution of dimethyl sulfoxide, and stirred at 65°C to 75°C to dissolve the starch; wherein, the aqueous solution of dimethyl sulfoxide The concentration is 90% to 97%. In addition, in order to ensure smooth formation of fiber network structure during subsequent electrospinning, the mass fraction of starch in the spinning solution is 20%-30%. ...

Embodiment 1

[0052] Accurately weigh 2.0 g of starch and add it to 10 mL of 95% dimethyl sulfoxide aqueous solution, stir magnetically at 70° C. to obtain a 20% (w / v) starch solution, stand at room temperature for defoaming, and obtain a spinning solution.

[0053] The spinning parameters are set as follows: the spinning ambient temperature is 60°C, the electrostatic field voltage is 20kV, the spinning distance is about 15cm, and the spinning solution flow rate is 1 mL / h. Starch nanofibrous membranes were prepared by electrospinning.

[0054] Soak the prepared starch nanofiber film in ethanol solution with a concentration of 0.1 mol / L stearic acid, react at 60°C for 1 hour, take it out, wash it with absolute ethanol, and dry it at room temperature to obtain a hydrophobic starch food packaging film.

Embodiment 2

[0056] Accurately weigh 2.5 g of starch and add it to 10 mL of 95% dimethyl sulfoxide aqueous solution, stir magnetically at 70° C. to obtain a 25% (w / v) starch solution, stand at room temperature for defoaming, and obtain a spinning solution.

[0057] The spinning parameters are set as follows: the spinning ambient temperature is 60°C, the electrostatic field voltage is 20kV, the spinning distance is about 15cm, and the spinning solution flow rate is 1 mL / h. Starch nanofibrous membranes were prepared by electrospinning.

[0058] Soak the prepared starch nanofiber film in ethanol solution with a concentration of 0.1 mol / L stearic acid, react at 60°C for 1 hour, take it out, wash it with absolute ethanol, and dry it at room temperature to obtain a hydrophobic starch food packaging film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com