Electrical control device and hydraulic control device in runway surface friction coefficient testing car

A friction coefficient and control device technology, which is applied in the field of automatic controller systems, can solve the problem of insufficient measurement response speed, control capability and data processing capability of electrical control devices, slow printing speed of friction coefficient and curve output, and unstable pressure holding value, etc. problems, to achieve the effect of improving stability and safety, improving measurement response speed, and reducing measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

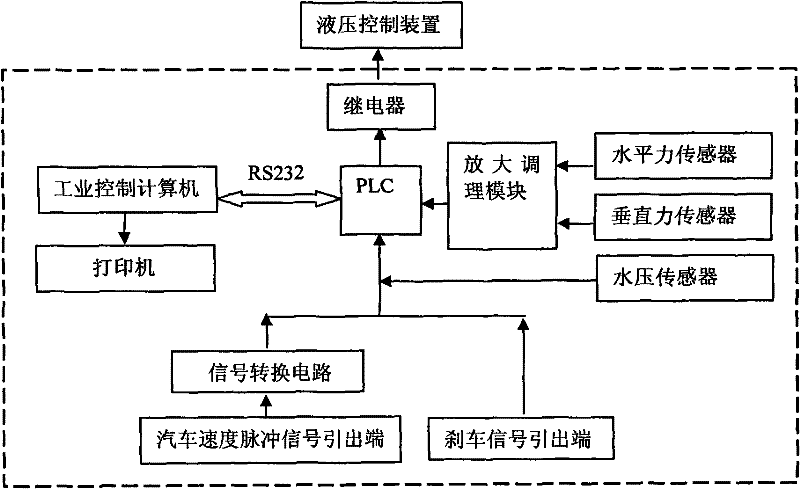

[0026] figure 1 In the shown embodiment, the electrical control device in the test vehicle for friction coefficient of airport pavement of the present invention includes industrial control computer, PLC, relay, power supply, printer, amplification conditioning module, sensor, signal conversion circuit, automobile speed pulse signal lead-out terminal And brake signal terminal. The RS232 serial communication bus is used to connect the industrial control computer and the PLC. In addition, the industrial control computer is also connected to the printer. The PLC is also directly connected to the relay, the amplification and conditioning module, the water pressure sensor, the signal conversion circuit and the brake signal terminal. The relay It is also connected to the hydraulic control device, specifically, the relay is connected to various valves and travel switch units in the hydraulic control device, the amplification and conditioning module is also connected to the horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com