High-strength nylon formula for blower impeller and preparation method thereof

A technology for blower blades and manufacturing methods, which is applied to components, mechanical equipment, machines/engines, etc. of pumping devices for elastic fluids, and can solve the problems of breaking the dynamic balance of blades, severe sediment friction, severe wear, etc., to achieve The production cost is low, the specific gravity is light, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

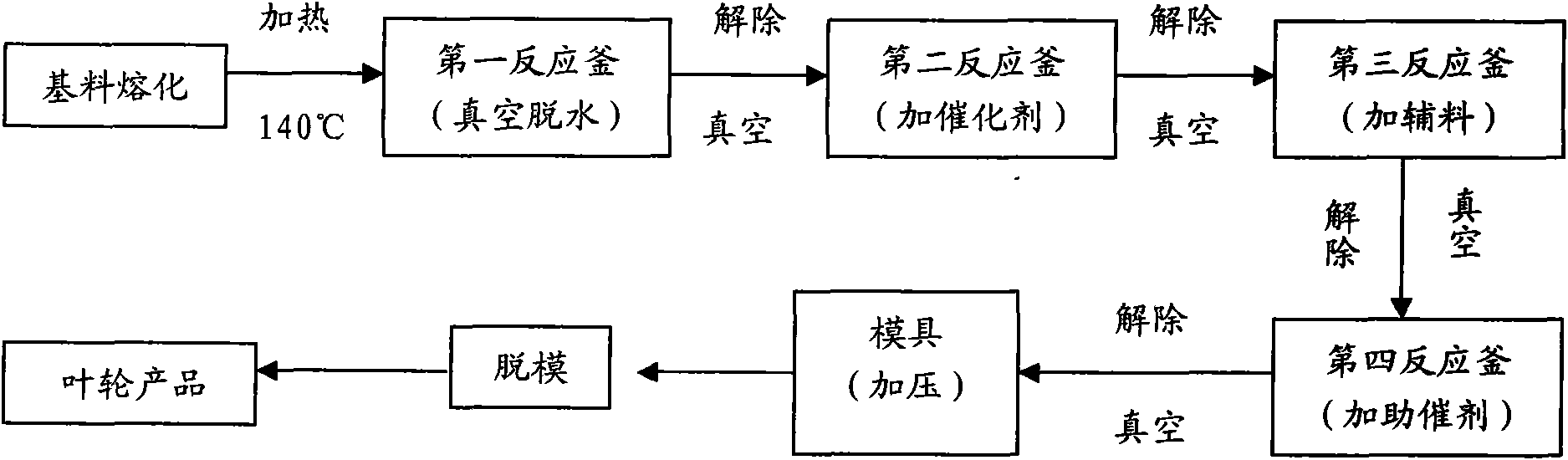

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: compare through trial and error, screen out the best formulation embodiment of the present invention as:

[0022] Base: caprolactam 80-82%, laurolactam 18-20%

[0023] Excipients: glass beads 4% carbon black 0.3%

[0024] NaOH 0.2% Triphenylmethane polyisocyanate 3.6%

[0025] HPT 3% DNPD 0.16%

[0026] PTFE 7% Melamine 2.5%

[0027] Molybdenum disulfide 0.4% Phthalocyanine blue 0.04%

[0028] The molded nylon prepared by the best formula of the invention has excellent physical and chemical properties and mechanical properties, and each index can meet the needs of the blower impeller.

[0029] The test results are as follows:

[0030] Tensile strength 87-95MPa Bending strength 96-110MPa

[0031] Shear strength 72-79MPa Notched impact strength 880kg / m 2 above

[0032] Compressive strength yield point 96-103MPa Rockwell hardness 115-120

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com