Rapid-imbibing foamed material with antibacterial property and preparation method thereof

A foam material and antibacterial technology, which is applied in the field of antibacterial fast liquid-absorbing foam material and its preparation, can solve the problems of no antibacterial performance and liquid absorption performance evaluation, complicated preparation process, etc., achieve excellent liquid absorption capacity, and easy to obtain raw materials , the effect of fast water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 70 grams of polyvinyl alcohol with a degree of polymerization of 2000 and a degree of alcoholysis of 99% are dissolved in 930 grams of 95°C hot water to form a 7% solution; adding mass fraction is 400 milliliters of 50% sulfuric acid, adding 5 grams of chitosan, adding 10 1 gram of sodium lauryl sulfate, 5 grams of sodium dibutylnaphthalene sulfonate, mixed evenly and poured into the stirrer, stirred for 20 minutes, and the system became emulsion; adding mass fraction was 60 milliliters of 37% formaldehyde solution, and then continued to stir for 10 Minutes; pour the above liquid into the mold, put it into a constant temperature box, react at 30°C for 40 hours, solidify and form, wash, and dry to obtain the target product.

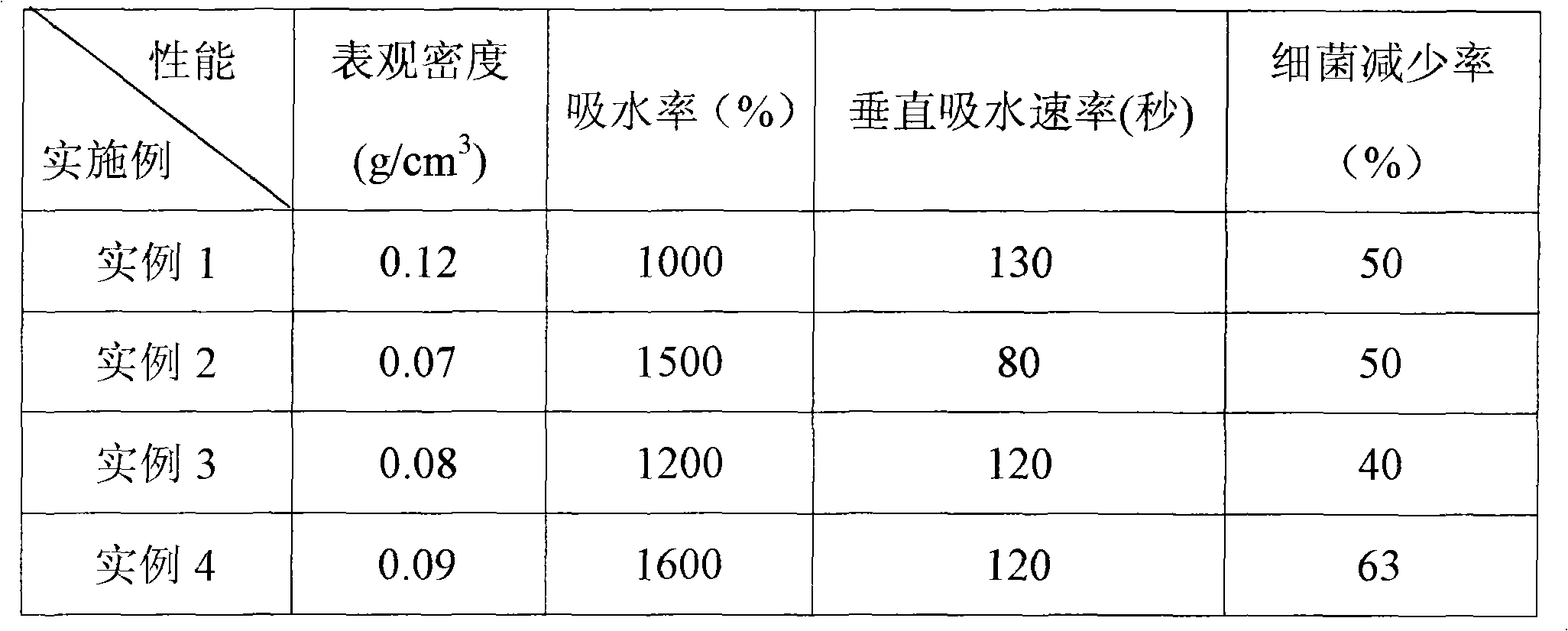

[0027] The performance test results are shown in Table 1.

Embodiment 2

[0029] 100 grams of polyvinyl alcohol with a degree of polymerization of 1700 and a degree of alcoholysis of 99% are dissolved in 900 grams of 95°C hot water to make a 10% solution; adding mass fractions is 500 milliliters of sulfuric acid, 5 grams of chitosan, and 10 10 grams of sodium lauryl sulfate, 10 grams of polyoxyethylene sorbitan monolaurate, mixed evenly and poured into the stirrer, stirred for 20 minutes, and the system became emulsion; adding mass fraction was 100 milliliters of 37% formaldehyde solution, Stirring was continued for another 10 minutes; the above liquid was poured into a mold, placed in a constant temperature box, and reacted at 40°C for 15 hours to solidify and form, washed, and dried to obtain the target product.

Embodiment 3

[0031] 300 grams of polyvinyl alcohol with a degree of polymerization of 1700 and a degree of alcoholysis of 99% and 200 grams of polyvinyl alcohol with a degree of polymerization of 1700 and a degree of alcoholysis of 88% are dissolved in 4500 grams of 95°C hot water to form a 10% solution; 2500 milliliters of 50% sulfuric acid, add 20 grams of chitosan, add 75 grams of polyoxyethylene sorbitan monooleate, 25 grams of polyoxyethylene sorbitan monolaurate, mix well and pour into the mixer, Stir for 20 minutes, the system becomes an emulsion; add 500 ml of formaldehyde solution with a mass fraction of 37%, and continue to stir for 30 minutes; pour the above liquid into a mold, put it in a constant temperature box, and react at 50°C for 10 hours to solidify and form, wash and dry , to get the target product.

[0032] The performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com