Electric control marking system for electrocorrosion marking production line

A production line, electro-corrosion technology, used in typewriters, printing devices, printing, etc., can solve the problems of marking fluid flowing on the work surface and workpiece, poor consistency of marking marks, and burning of electrical equipment by users, so as to prevent marking. The effect of fluid flow, uniform marking and low labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

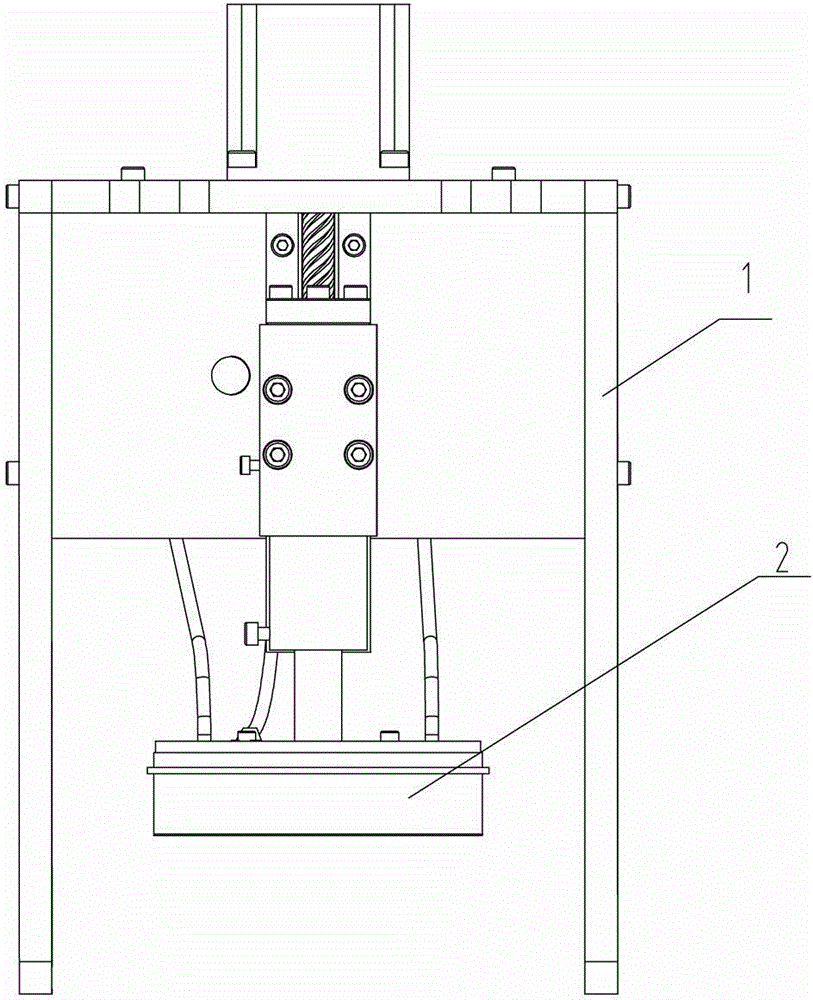

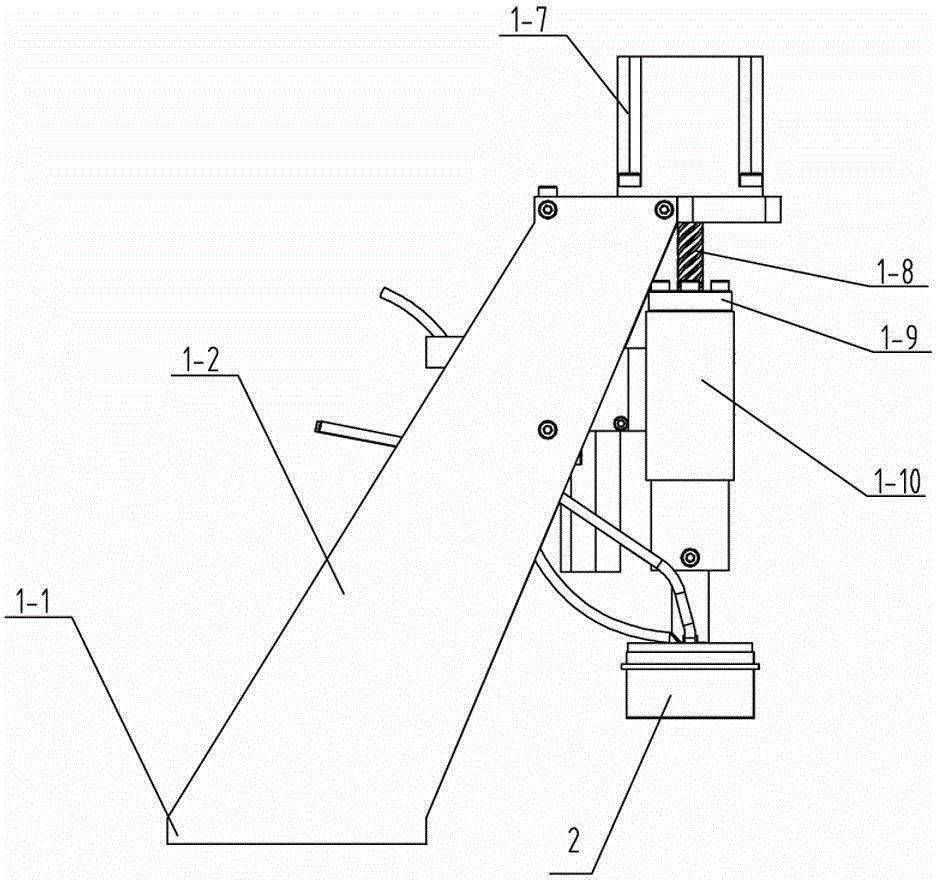

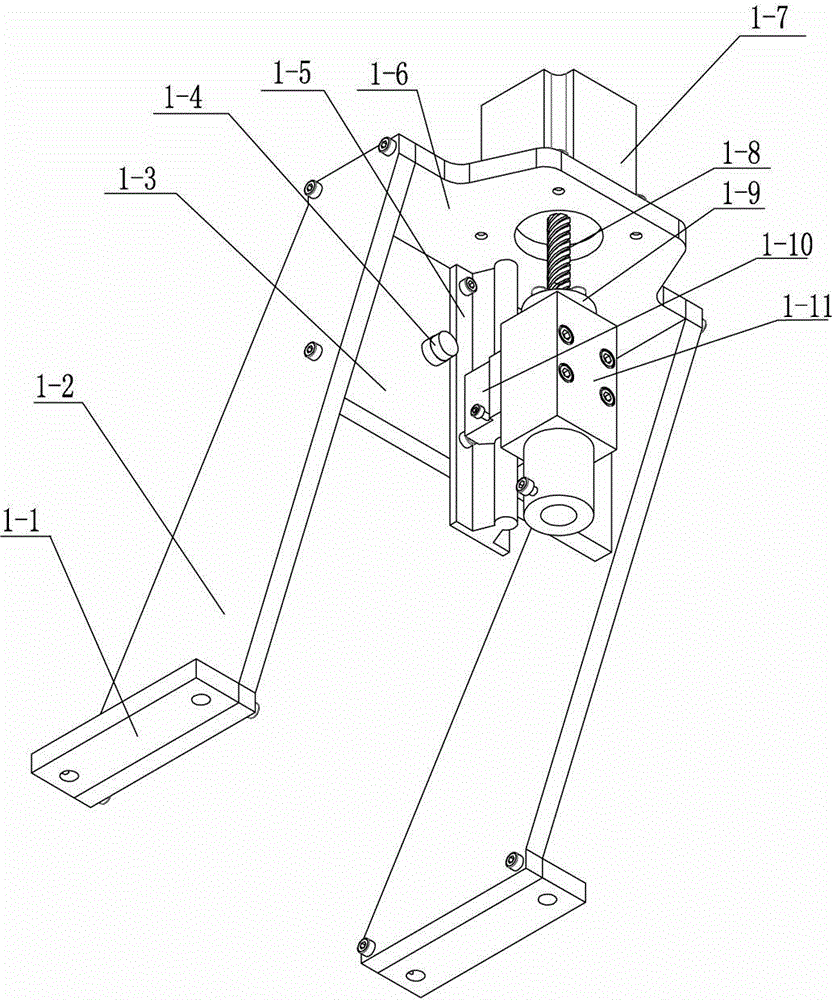

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the electrical control marking system for the electro-corrosion marking production line of the present invention includes a marking actuator 1 and a marking head 2 connected to the marking actuator 1, and the marking actuator 1 includes a fixed frame and The marking drive device installed on the fixed frame, the described marking head includes plexiglass liner 2-4, fixed frame 2-8, graphite block 2-5, carbon felt 2-7, conductive mesh 2-6, The electrode sheet 2-3, the marking head positioning sleeve 2-10 and the wire 2-1 connected with the electrode sheet 2-3 have internal threaded holes at both ends of the plexiglass lining plate 2-4. Block 2-5 is also provided with a threaded hole at the position corresponding to the plexiglass liner 2-4, and the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com