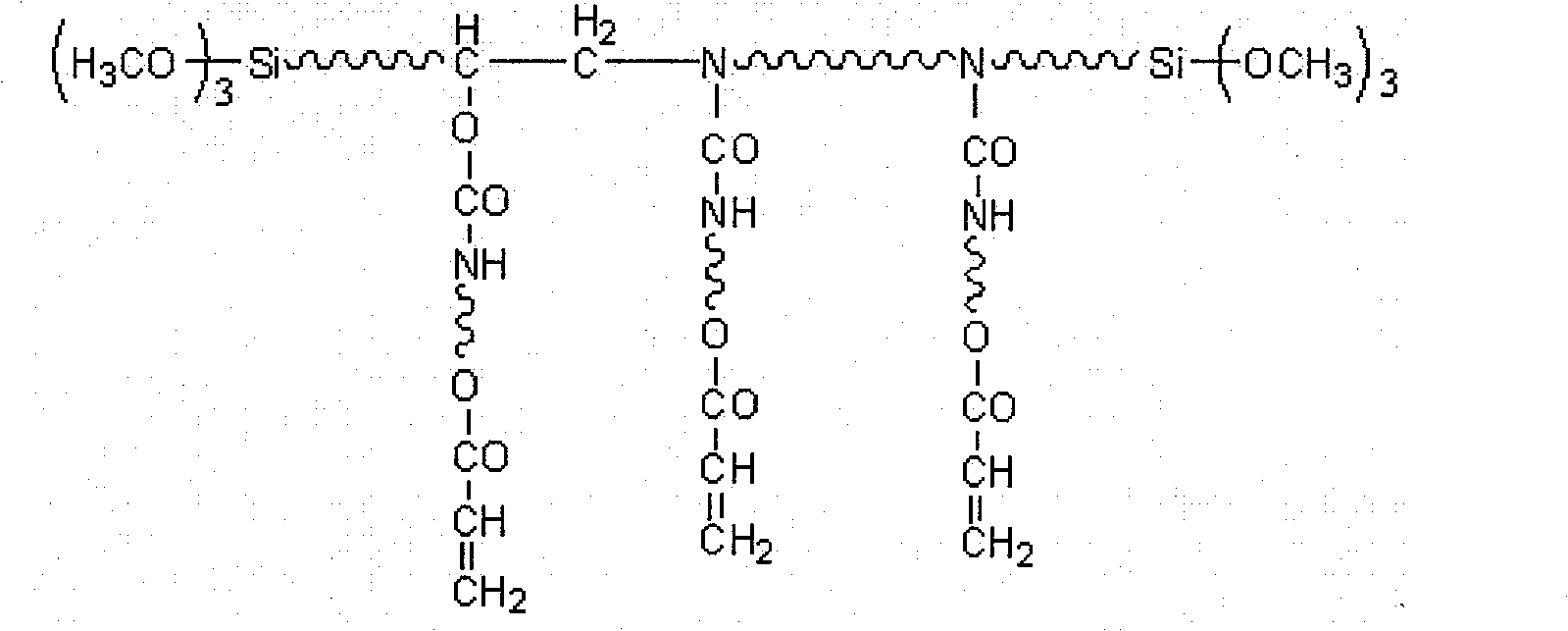

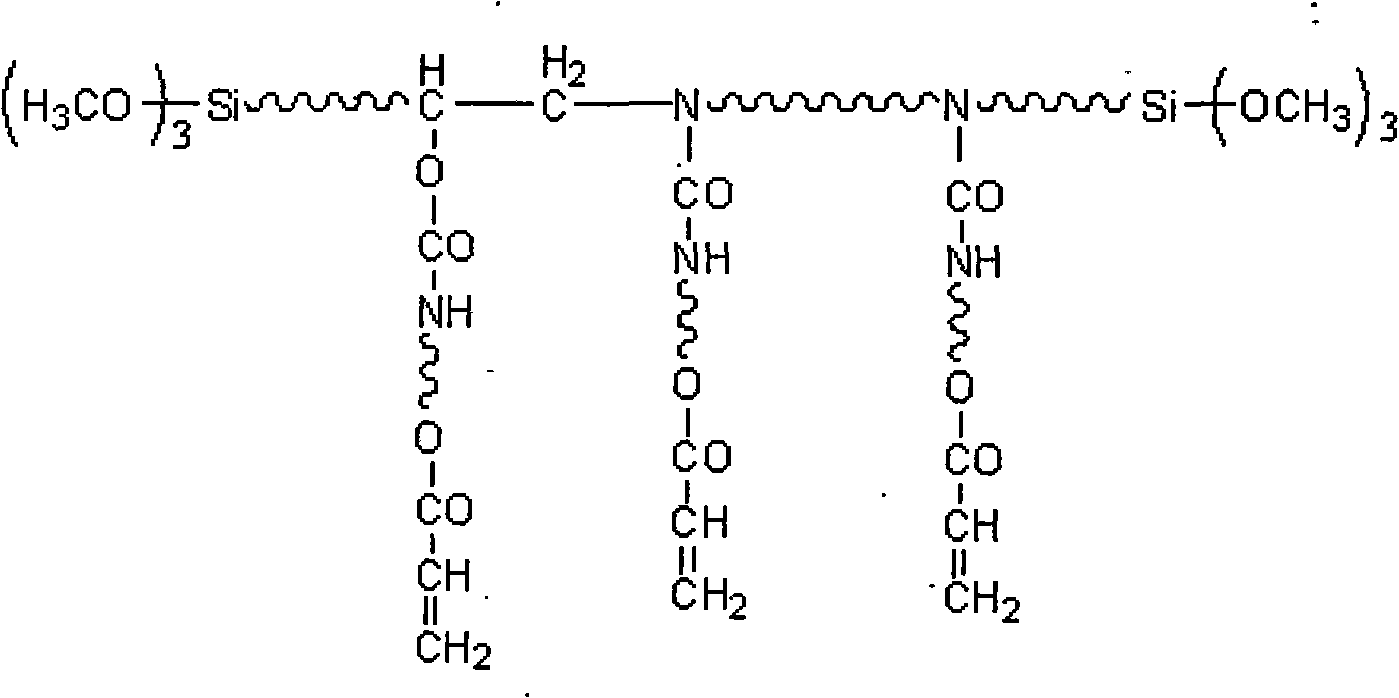

Three-functionality-degree organosilicon polyurethane acrylate and synthetic method thereof

A technology of polyurethane acrylate and trifunctionality, which is applied in the field of synthesis of urethane acrylate modified by silane coupling agent, can solve the problems of poor product compatibility, small molecular weight and wide molecular weight distribution, and achieve good compatibility and high molecular weight. The effect of narrow distribution and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

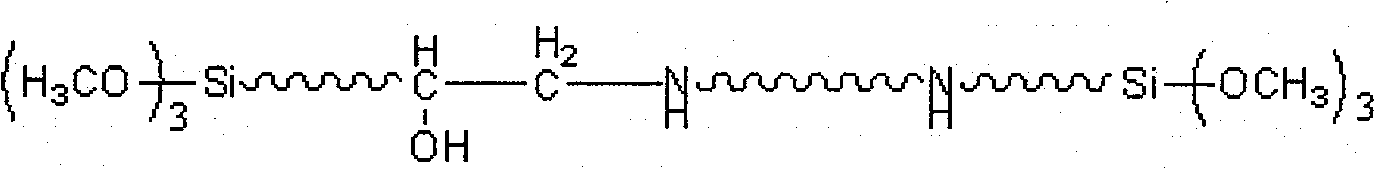

[0027] Example 1, weigh 10g of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane (KH-792), add to 11g of γ-(2,3-epoxypropoxy)propyl trimethyl Oxysilane (KH-560), placed in a three-necked flask, mixed evenly, then heated to 70°C for 2 hours to react to obtain a modified silane coupling agent containing three active hydrogen functional groups;

[0028] Vacuumize 100g of PTMG at 110°C for 2 hours to remove the doped water; then lower the temperature to 50°C, add 28.5g of TDI, wait until the temperature is constant, raise the temperature to 85°C and react for 2 hours until the NCO content reaches the design value Stop heating to obtain polyurethane prepolymer one with NCO groups at both ends;

[0029] After mixing 100g of polyurethane prepolymer 1 and 5.6g of hydroxyethyl acrylate, react at 80°C for 2 hours to obtain polyurethane prepolymer 2 with an NCO group at one end;

[0030] Mix 100g of polyurethane prepolymer II with 6.9g of modified silane coupling agent and react at 70°C fo...

Embodiment 2

[0031] Example 2, weigh 10g N-(β-aminoethyl)-γ-aminopropyltriethoxysilane (WD-52), add to 9.6g γ-(2,3-epoxypropoxy)propane Base trimethoxysilane (KH-560), placed in a three-necked flask, mixed uniformly, and then heated to 50 ° C for 3 hours to react to obtain a modified silane coupling agent containing three active hydrogen functional groups;

[0032] Vacuumize 100g of HTPB at 100°C for 3 hours to remove the doped water; then lower the temperature to 40°C, add 24.6g of IPDI, wait until the temperature is constant, raise the temperature to 70°C and react for 3 hours until the NCO content reaches the design value Stop heating to obtain polyurethane prepolymer one with NCO groups at both ends;

[0033] After mixing 100g of polyurethane prepolymer 1 and 5.9g of hydroxyethyl methacrylate, react at 80°C for 2 hours to obtain polyurethane prepolymer 2 with an NCO group at one end;

[0034] Mix 100g of polyurethane prepolymer II with 7.6g of modified silane coupling agent and react ...

Embodiment 3

[0035] Example 3, weigh 10g N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane (WD-53), add to 13.4g γ-(2,3-glycidyloxy ) Propyltrimethoxysilane (KH-560), placed in a three-necked flask, mixed uniformly, and then heated to 90°C for 1 hour to react to obtain a modified silane coupling agent containing three active hydrogen functional groups;

[0036] Vacuumize 100g of PTMG and 210 at 115°C for 1.5 hours to remove the doped water; then cool down to 60°C, add 30.5g of MDI, wait for the temperature to be constant and raise the temperature to 90°C for 1 hour until the NCO content reaches the designed value, stop heating, promptly obtain the two ends as the polyurethane prepolymer one of NCO group;

[0037] After mixing 100g of polyurethane prepolymer 1 and 5.7g of hydroxypropyl acrylate, react at 70°C for 3 hours to obtain polyurethane prepolymer 2 with an NCO group at one end;

[0038] Mix 100g of polyurethane prepolymer II with 5.6g of modified silane coupling agent and react a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com