Drought-resistant energy plant seed pelleting agent, preparation method and using method thereof

A granulation agent and pelletization technology, applied in botany equipment and methods, plant growth regulators, seed and rhizome treatment, etc., can solve the problems of increasing emergence rate, uneven emergence, and easy cracking of pellet-coated seeds and other issues to achieve the effect of improving stress resistance and germination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

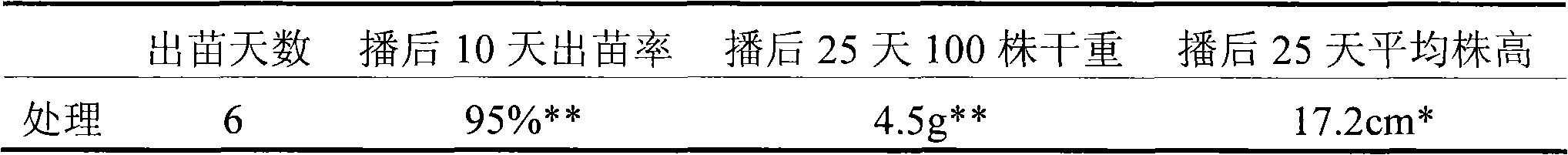

Embodiment 1

[0060] 1. Preparation of pelletizing agent

[0061] Components and content of pellet coating agent:

[0062] 25 parts of peanut shell powder

[0063] Commercially available 91.4% uniconazole 0.04 parts

[0064] Polyacrylamine resin 240 mesh 8 parts

[0065] Attapulgite 55 parts

[0066] Sodium carboxymethyl cellulose 3 parts

[0067] Commercially available 97% Carbofuran 0.3 parts

[0068] Commercially available 50% carbendazim 0.5 parts

[0070] urea 5 parts

[0071] Potassium dihydrogen phosphate 5 parts

[0072] Prepare drought-resistant energy plant seed pellets according to the following method:

[0073] 1. 25 parts of 100 mesh peanut shell powder, 8 parts of 240 mesh polyacrylamide resin (purchased from Baoding Kehan Resin Co., Ltd.), 3 parts of 100 mesh sodium carboxymethyl cellulose and 55 parts of 100 mesh attapulgite, Put 5 parts of 100-mesh urea and 5 parts of 100-mesh potassium dihydrogen phosphate into a mixer and mix th...

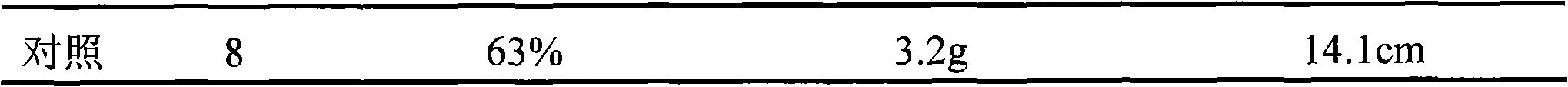

Embodiment 2

[0095] 1. Preparation of pelletizing agent

[0096] Components and content of pellet coating agent:

[0097] 20 servings of peanut shell powder

[0098] GGR root powder 0.06 parts

[0099] Polystarch grafted acrylic resin 240 mesh 7 parts

[0100] Attapulgite 60 parts

[0101] Sodium carboxymethyl cellulose 4 parts

[0102] Commercially available 97% Carbofuran 0.3 parts

[0103] Commercially available 50% carbendazim 0.5 parts

[0105] urea 5 parts

[0106] Potassium dihydrogen phosphate 5 parts

[0107] Wherein, the GGR rooting powder used is ABT rooting powder No. 6 sold by the ABT Research Center of the Chinese Academy of Forestry.

[0108] Prepare drought-resistant energy plant seed pellets according to the following method:

[0109] 1. With 20 parts of 100 mesh peanut shell powder, 7 parts of 240 mesh polystarch grafted acrylic resin (purchased from Baoding Kehan Resin Co., Ltd.), 4 parts of 100 mesh sodium carboxymethyl cellulose...

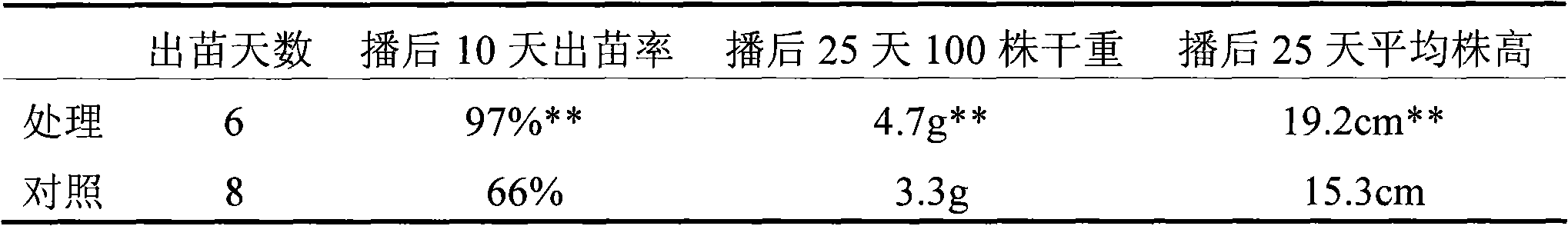

Embodiment 3

[0130] 1. Preparation of pelletizing agent

[0131] Components and content of pellet coating agent:

[0132] 20 servings of peanut shell powder

[0133] GGR root powder 0.06 part

[0134] Polystarch grafted acrylic resin 240 mesh 7 parts

[0135] Attapulgite 60 parts

[0136] Sodium carboxymethyl cellulose 4 parts

[0137] Commercially available 97% Carbofuran 0.3 parts

[0138] Commercially available 90% thiabendazole 0.5 parts

[0139] Magnesium sulfate 1.2 parts

[0140] urea 5 parts

[0141] Potassium dihydrogen phosphate 5 parts

[0142] Wherein, the GGR rooting powder used is ABT rooting powder No. 6 sold by the ABT Research Center of the Chinese Academy of Forestry.

[0143] Prepare drought-resistant energy plant seed pellets according to the following method:

[0144] 1. 20 parts of 100 mesh peanut shell powder, 7 parts of 240 mesh polystarch grafted acrylic resin (purchased from Baoding Kehan Resin Co., Ltd.), 4 parts of 100 mesh sodium carboxymethyl cellu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com