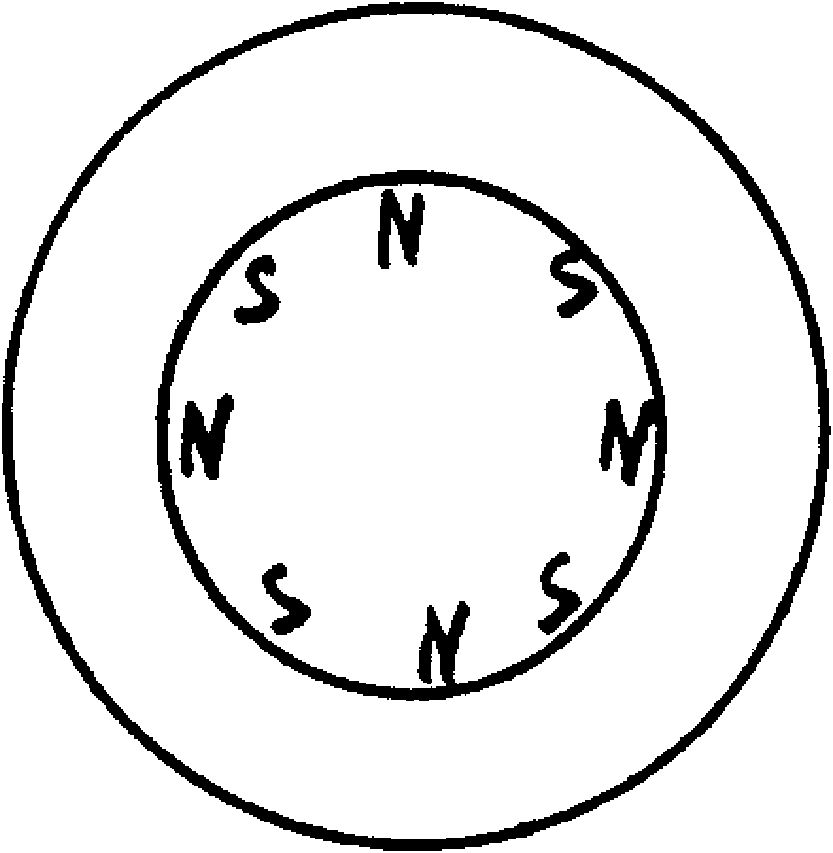

Method for manufacturing anisotropic multi-pole magnetic ring through dry-press forming

An anisotropic, dry press forming technology, applied in the manufacture of inductors/transformers/magnets, manufacturing stator/rotor bodies, magnetic materials, etc., can solve problems such as low yield, cracking, inconsistent shrinkage of upper and lower end surfaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

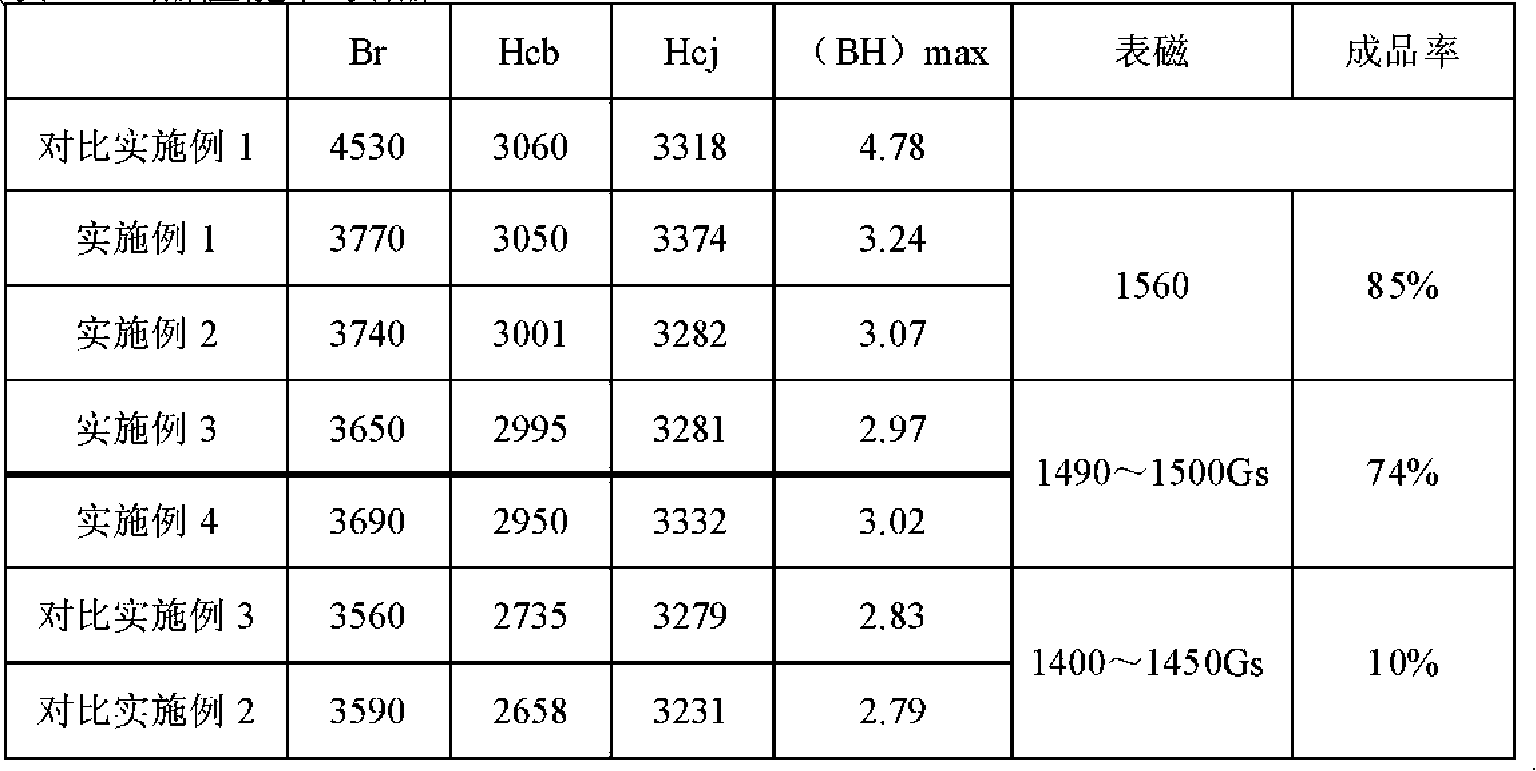

Examples

Embodiment 1

[0022] The base material adopts the formula in the patent application number 200510023312.5 (magnet powder, sintered magnet manufacturing method and its products), and the pre-sintered material includes a hexagonal ferrite main phase containing A, R, B and Fe, and has the following characteristics Molecular formula: A 1~ x R x [(Fe 3+ a Fe 2+ b ) 12~y B y ] z o 19 , where A represents one or two elements of Sr and Ba; R represents at least one element selected from rare earth elements and Bi, and must contain La; B represents Co, Ti, Mn, Zn, Ge, As and at least one element in W, which must contain Co, and the valence of the Co element is positive trivalent; wherein, a+b is equal to 1; z is preferably 0.9 to 1.1; a is preferably 0.97 to 0.999, and b is preferably 0.001 to 0.03 ; The preferred ranges of x and y are: 0≤x≤0.54, 0.≤y≤0.45.

[0023] The specific process of dry pressing anisotropic multi-pole magnetic ring is as follows:

[0024] 1. Ball milling process ...

Embodiment 2

[0035] The specific process of dry pressing anisotropic multi-pole magnetic ring is as follows:

[0036] 3. Pre-compression pre-magnetization granulation process

[0037] First, the dried powder is mixed with the binder methylcellulose solution, the binder ratio is 40wt%, then magnetized in a magnetic field, then dried, and finally the powder is pulverized by a high-speed pulverizer, and passed A 60-mesh sieve was used to obtain dry-pressed permanent magnet ferrite radial molding powder. The pre-compression pressure is 10Mpa, and the pre-magnetization magnetic field is 5000Oe.

[0038] 4. Radial forming process

[0039] The permanent magnet ferrite radial multi-pole magnetic ring is formed on a 45T experimental press, the pressure is 3MPa, the water content of the dry-pressed magnetic powder before forming is 0.2wt%, and the forming radial magnetic field is 10000Oe. It is pressed and formed by double-sided isostatic pressing.

[0040] All the other are identical with embod...

Embodiment 3

[0042] The specific process of dry pressing anisotropic multi-pole magnetic ring is as follows:

[0043] 3. Pre-compression pre-magnetization granulation process

[0044] First, the dried powder is mixed with a binder methylcellulose solution, the binder ratio is 40wt%, and then magnetized in a magnetic field with a pre-compression pressure of 25Mpa and a pre-magnetization magnetic field of 6500Oe. Then dry again, and finally pulverize the powder with a high-speed pulverizer and pass through a 60-mesh sieve to obtain the powder for radial molding of dry-pressed permanent magnet ferrite. After drying, pre-compression and pre-magnetization are carried out, the pre-compression pressure is 25Mpa, and the pre-magnetization magnetic field is 6500Oe.

[0045] 4. Radial forming process

[0046] The permanent magnet ferrite radial multi-pole magnetic ring is formed on a 45T experimental press, the pressure is 3MPa, the water content of the dry-pressed magnetic powder before forming i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com