Method for producing nikkomycin Z, special culture medium of nikkomycin Z and special engineering bacteria of nikkomycin Z

A technology of nikkomycin and culture medium, applied in the field of production of nikkomycin Z, can solve the problems of expensive reagents, unsuitable for large-scale industrial production, inability to effectively separate X components and Z components, etc. The effect of reducing production costs and simplifying separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

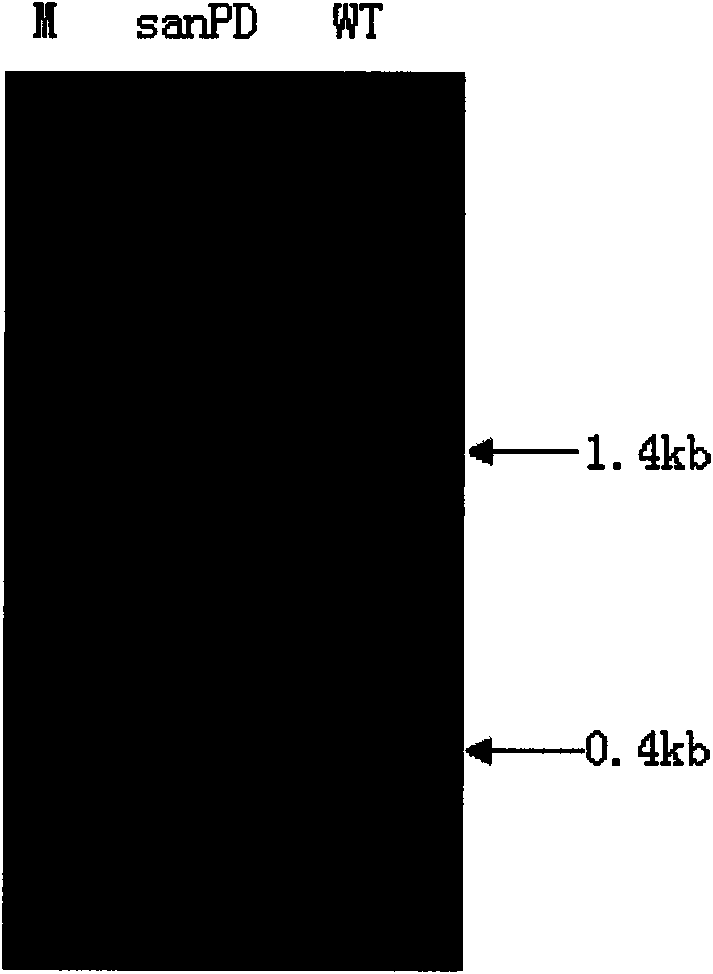

[0026] Example 1. Construction of Streptomyces ansochromogenes TH322 sanPD CGMCC No. 3086

[0027] The nikkomycin-producing strain used in this example is Streptomyces chromogenes TH322. Streptomyces chromogenes TH322 is a strain obtained by mutagenesis of Streptomyces chromogenes 7100 CGMCC 4.321 (purchased from the General Microbiology Center of China Microbial Culture Collection Management Committee). The spores of Streptomyces chromogenes 7100 CGMCC 4.321 (purchased from the General Microbiology Center of the China Microbial Species Collection and Management Committee) are filamentous hooks, or coils, rarely forming rings; the spores are spherical or oval. The initial yield of Nicomycin Z from Streptomyces chromogenes TH322 was 350 mg / L.

[0028] The genomic DNA of Streptomyces chromogenes 7100 CGMCC 4.321 was extracted, digested with Sau3AI, and separated by pulse electrophoresis to recover 40-50kb DNA fragments. At the same time, the cosmid plasmid supercos1 (Stratagene) was...

Embodiment 2

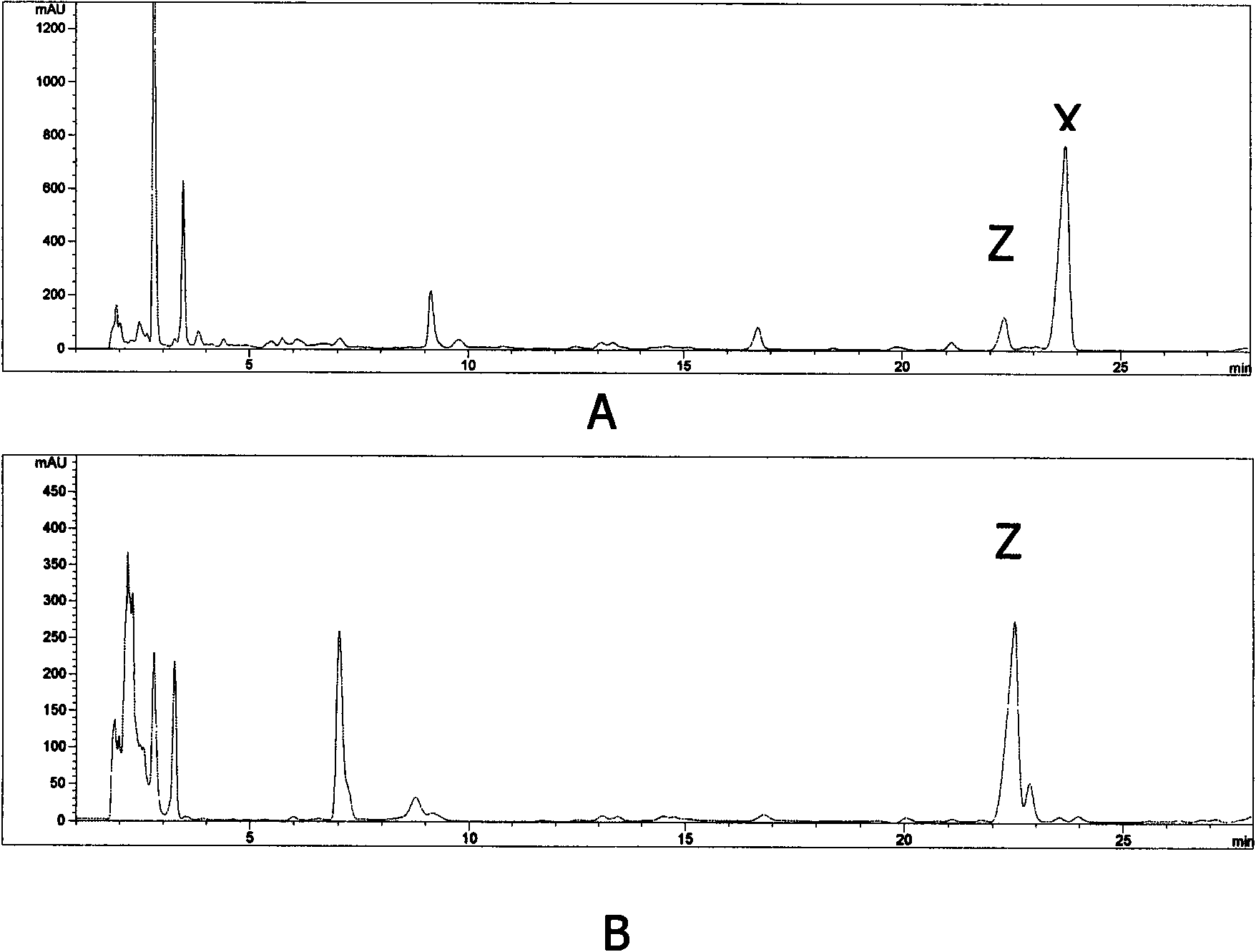

[0033] Example 2: HPLC analysis and biological activity detection of the fermentation product of Streptomyces ansochromogenes TH322 sanPD CGMCC No. 3086

[0034] 1) Preparation of fermentation product of Streptomyces ansochromogenes TH322 sanPD CGMCC No.3086

[0035] Inoculate Streptomyces ansochromogenes TH322 sanPD CGMCC No.3086 on YEME medium (Difco Yeast Extract 3g, Difco Tryptone 5g, OxoidMalt Extract 3g, Sucrose 200g, and distilled water to dilute to 1000ml before use. Add the following sterilized solution: MgCl 2 ·6H 2 O (2.5M) 2ml, Glucose (50%) 20ml, Glycine (10%) 50ml), 28°C, rotating speed 180rpm, after 48h incubation, transfer 1ml of bacterial solution to 50ml fermentation medium SP medium, 28°C, rotating speed After culturing at 180 rpm for 5 days, the fermentation broth was collected by centrifugation. The fermentation experiment was repeated 3 times.

[0036] The SP medium was prepared as follows: 30g glucose, 30g mannitol, 5g soy peptone, 8g yeast extract, dissolve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com