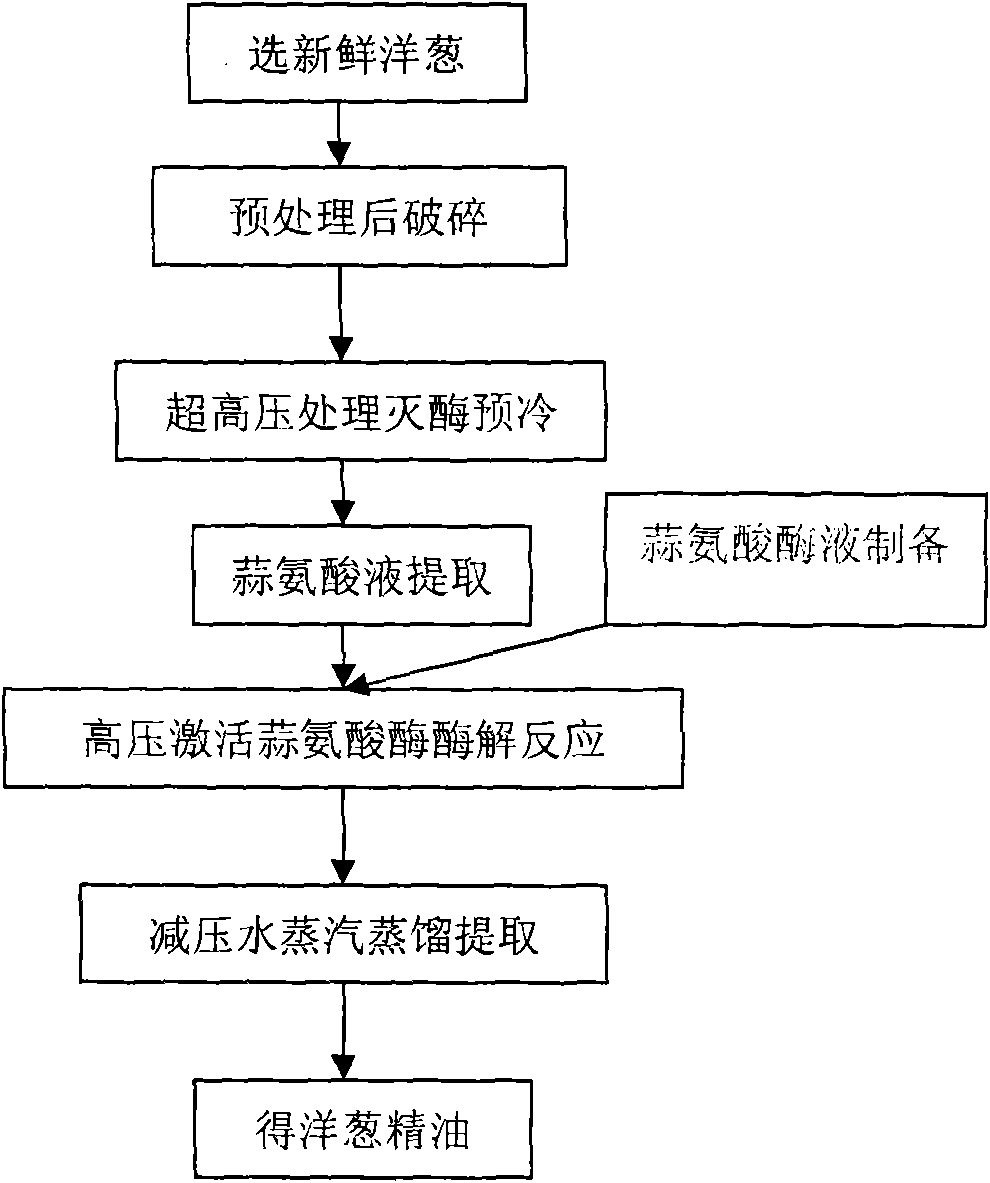

Method for extracting onion essential oil through ultrahigh pressure regulation of alliinase reaction

The technology of onion essential oil and alliinase, which is applied in the field of deep processing of agricultural products, can solve the problems of difficult control of reaction process, large loss of active substances, unstable product quality, etc., so as to avoid interference and residue, less irritation and mild taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Raw material processing: Select 0.75 kg of three parts of purple onion and put them into ultra-high pressure special bags for ultra-high pressure treatment (pressure 660Mpa, time 5min), take them out and store them in an environment of -20°C for later use.

[0022] 2. Extraction of alliin:

[0023] Mix methanol, chloroform, and water at a ratio of 12:5:3 to form a 1000mL mixed system (MCW for short). After mixing, put the onion treated with ultra-high pressure into it, and soak it at -20°C for 2 hours. Then take the onion out and soak it in 80% ethanol solution for 2 hours; add about 450mL of chloroform and 550mL of water to the MCW extract after taking out the onion, oscillate and mix well in the separatory funnel, let it stand for stratification, and take the upper phase methanol / water solution , add the ethanol extract and mix, evaporate to 500mL (50°C) in a rotary evaporator, then dilute to volume with 0.01mol / L pH7.5 phosphate buffer to obtain 1000mL of onion al...

Embodiment 2

[0029] Raw material processing: Select three parts of 0.75kg white onion and put them into special ultra-high pressure bags for ultra-high pressure treatment (processing pressure 630Mpa, time 10min), take them out and store them in an environment of -20°C for later use.

[0030] The preparation of the onion alliinase solution and the extraction of alliin are the same as in Example 1.

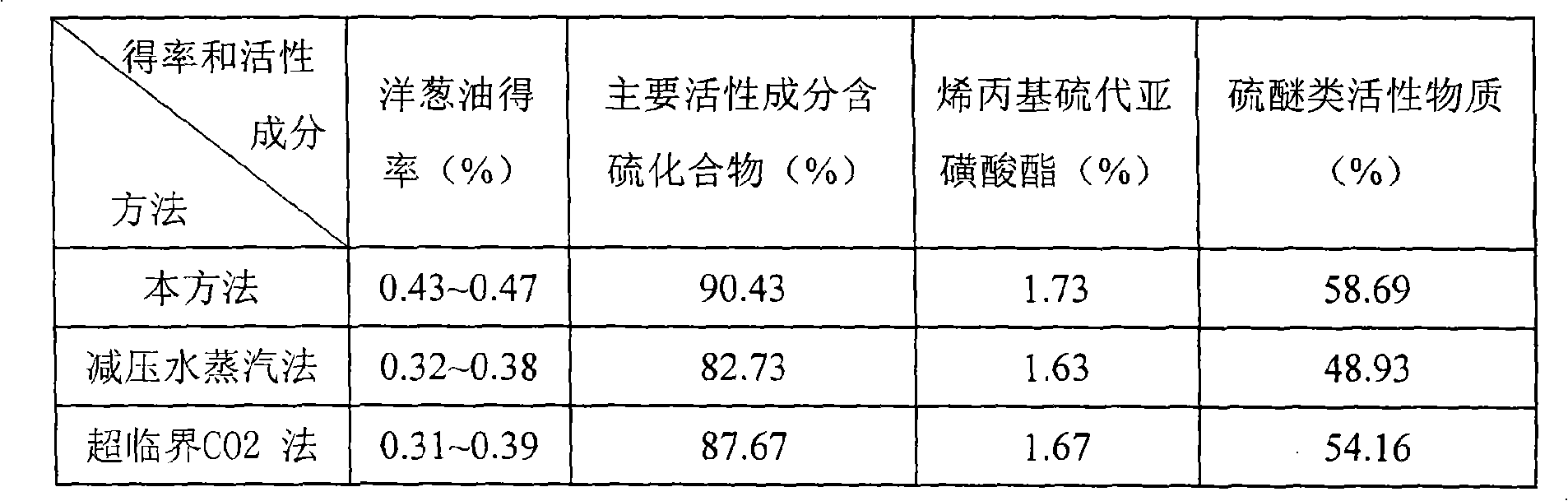

[0031] Extraction of Onion Essential Oil by Enzyme Catalyzed Reaction

[0032] Mix the extracted 1000mL alliin solution and 250mL alliinase solution, and carry out the enzyme-catalyzed reaction in the pressure chamber under the conditions of pH 6.6, pressure 180MPa, enzymolysis temperature 40°C, and enzymolysis time 30min, and the reaction ends Afterwards, the vacuum steam distillation technique (distillation vacuum degree 6kPa, extraction time 5h, sodium chloride addition amount 80g / 1000mL) was used to extract onion essential oil. The yield of onion essential oil extracted by this method is 0....

Embodiment 3

[0034] Raw material processing: Three parts of 0.75 kg yellow onion were selected and packed into special ultra-high pressure bags for ultra-high pressure treatment (treatment pressure 600Mpa, time 15min), and taken out and placed in a -20°C environment for later use.

[0035] The preparation of the onion alliinase solution and the extraction of alliin are the same as in Example 1.

[0036] Extraction of Onion Essential Oil by Enzyme Catalyzed Reaction

[0037]Mix the extracted 1000mL alliin solution and 250mL alliin enzyme solution, and carry out the enzyme-catalyzed reaction in the pressure chamber under the conditions of pH 6.6, pressure 200MPa, enzymolysis temperature 45°C, and enzymolysis time 40min, and the reaction ends Afterwards, the vacuum steam distillation technique (distillation vacuum degree 8kPa, extraction time 4h, sodium chloride addition amount 70g / 1000mL) was used to extract the onion essential oil. The yield of onion essential oil extracted by this method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com