Double cup cover ion source filament seat structure for preventing metal spraying

A technology of metal spraying and ion source, applied in the field of ion source, can solve problems such as filament fusing, insulation structure failure, and susceptibility to plasma bombardment, and achieve the effects of avoiding short circuit, prolonging service life, and reducing plasma bombardment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

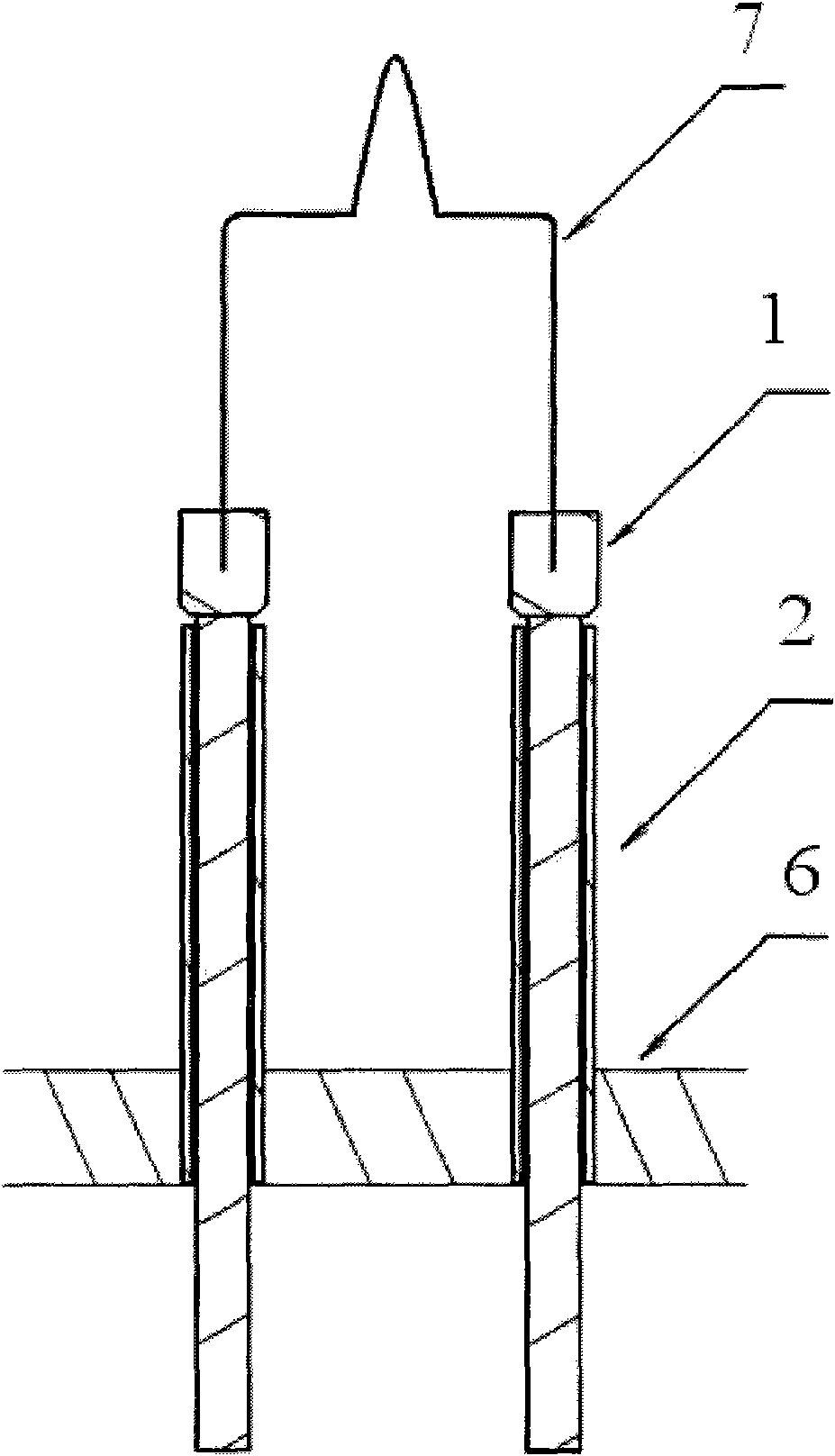

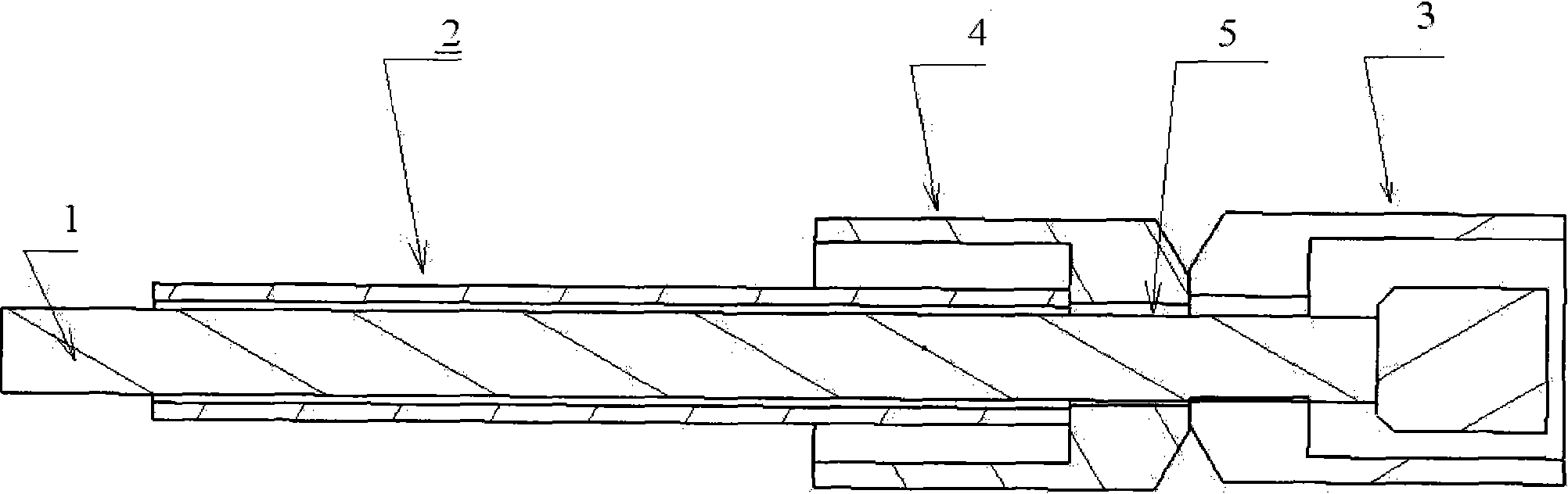

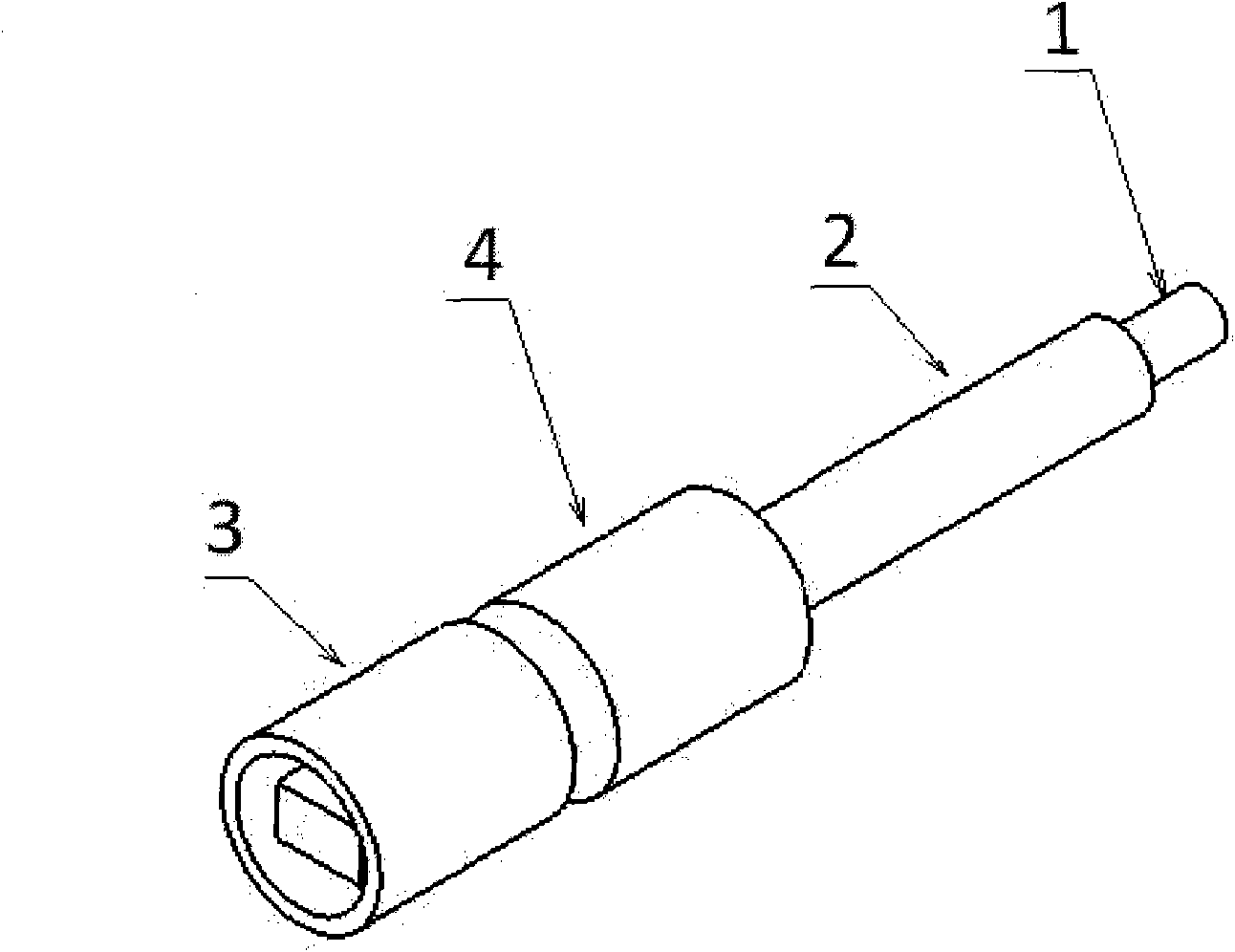

[0017] Such as figure 2 and image 3 In the shown anti-metal spraying double-cup ion source filament holder structure, the insulating cover is reversed cylindrical upper and lower cups 3 and 4, and the cup material is ceramic; the electrode is a rod-shaped molybdenum rod 1, One end of the molybdenum rod 1 is a rectangular block structure; the other end of the molybdenum rod 1 is covered with a ceramic straight tube 2; one end of the upper cup 3 is open, and the other end is opened with a small round hole, and the upper cup 3 completely covers the molybdenum rod 1 is a rectangular block structure; the end of the lower cup 4 in contact with the upper cup 3 is a solid part, and the solid part is opened with a round through hole 5, and a ceramic straight pipe 2 is also arranged in the lower cup 4, and the outer ceramic straight pipe 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com