High-temperature and high-moisture resistant coating for metalster and preparation method thereof

A technology of metal film resistors and high temperature resistance, which is applied in the direction of fireproof coatings, epoxy resin coatings, coatings, etc., can solve the problems of moisture resistance and heat resistance that cannot meet the needs of special fields, and achieve high temperature resistance and high temperature resistance Excellent wet performance, smooth film-forming surface, and good high-humidity resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Prepare according to the following mass ratio:

[0022] Coating base: bisphenol A type epoxy resin E-20 30%,

[0023] Methylhexahydrophthalic anhydride 19.5%.

[0024] Ethylene glycol 8%

[0025] Butanediol 2%,

[0026] Accelerator Hexamethyldisilazane 1.5%,

[0027] nano-SiO 2 2%,

[0028] Diluent absolute ethanol 37%.

[0029] Specific operation: measure according to the formula, mix epoxy resin, acid anhydride curing, polyol and absolute ethanol at room temperature, and disperse nano-SiO 2 The absolute ethanol suspension is added to the above mixture and mixed evenly, and the specific gravity of the coating is adjusted with diluent absolute ethanol under stirring conditions to be suitable for coating metal film resistors on the production line. The inner surface is cured and dried at 170°C for 2 minutes, and completely cured and dried within 45 minutes.

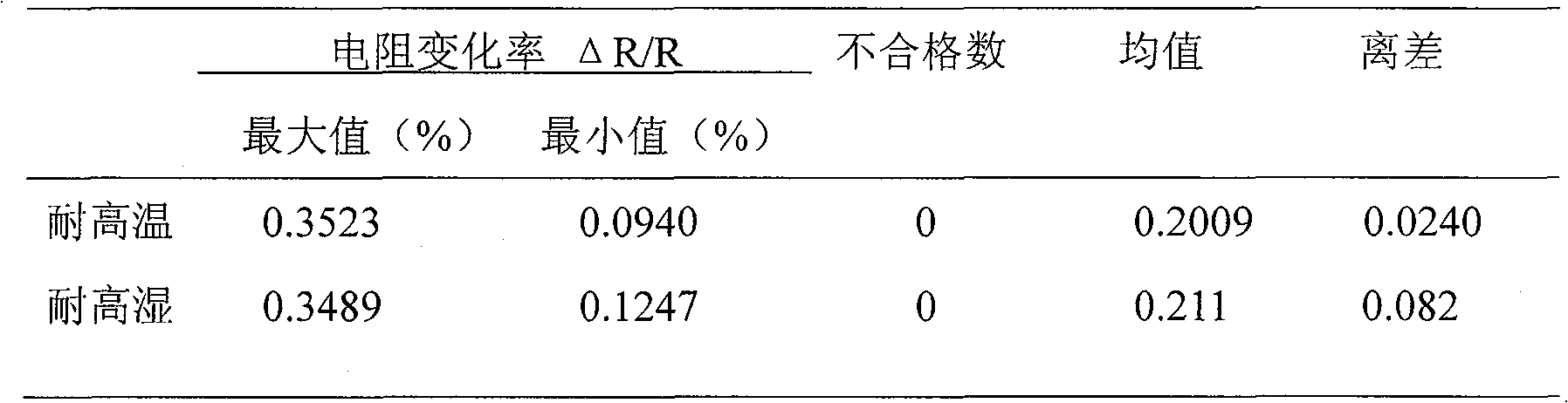

[0030] The high-temperature and high-humidity environment simulation test is ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com