Graded zinc diffusing method based on MOCVD (Metal-Organic Chemical Vapor Deposition) system for producing chip of indium-gallium-arsenic photoelectric detector

A technology of photodetector and diffusion method, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of low P-InP carrier concentration, complex process, low doping impurities, etc. Production, process repeatability, precise control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The applicant found the following points in the research:

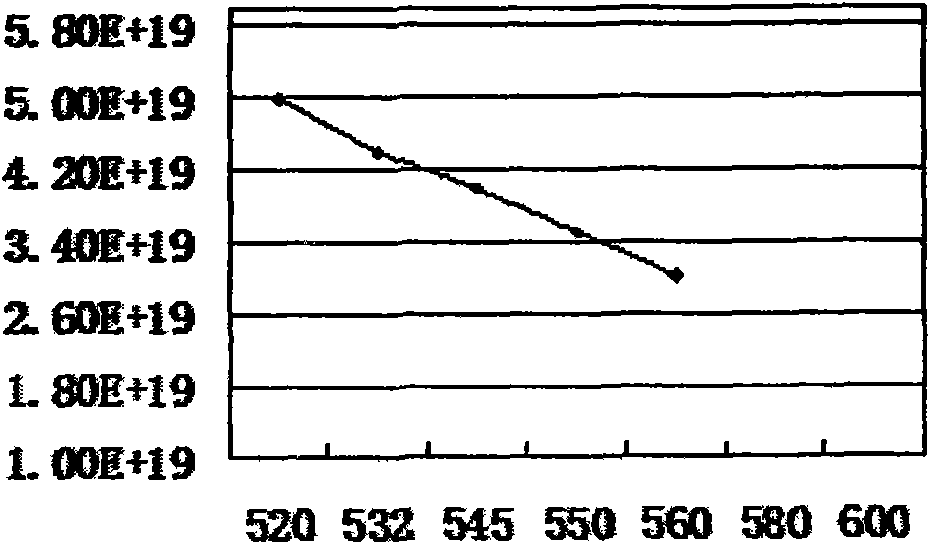

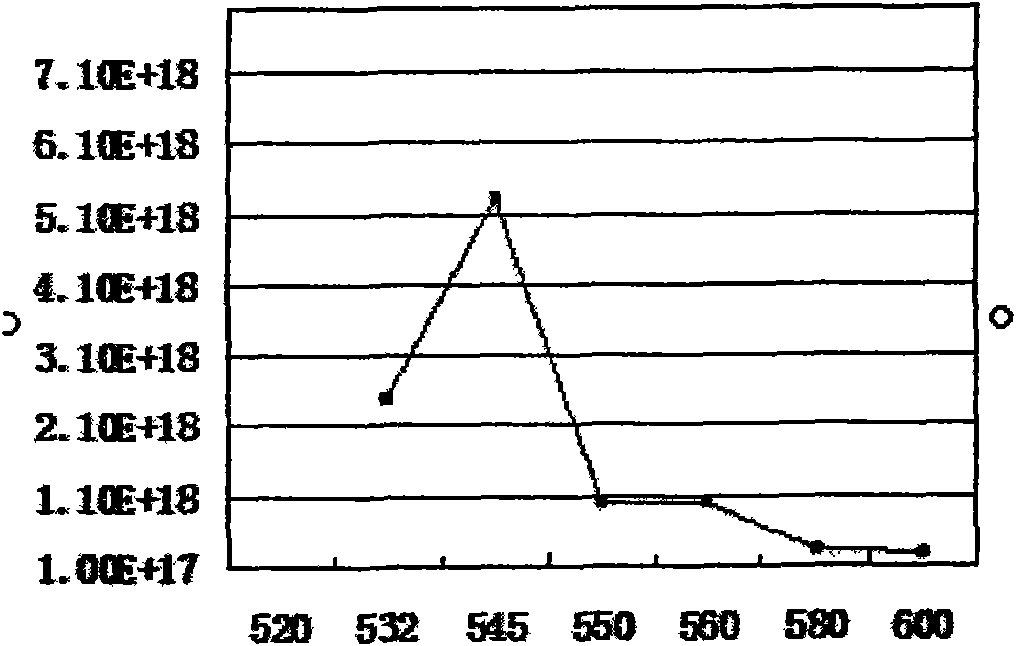

[0026] 1. There is a big difference in the diffusion law of zinc in InP and InGaAs materials. It is easy to diffuse in InP materials, but the diffusion rate of zinc in InGaAs materials is slow.

[0027] 2. There is a certain limit to the diffusion depth. For detectors with InGaAs PIN structure, the InGaAs layer needs to have a higher carrier concentration, but the zinc at this flow rate has oversaturated the InP layer, which will cause adverse effects, and between InP and InGaAs The interface formed by the material is not clear enough, and it is easy to accumulate too many charged particles at the junction of the InP and InGaAs interface.

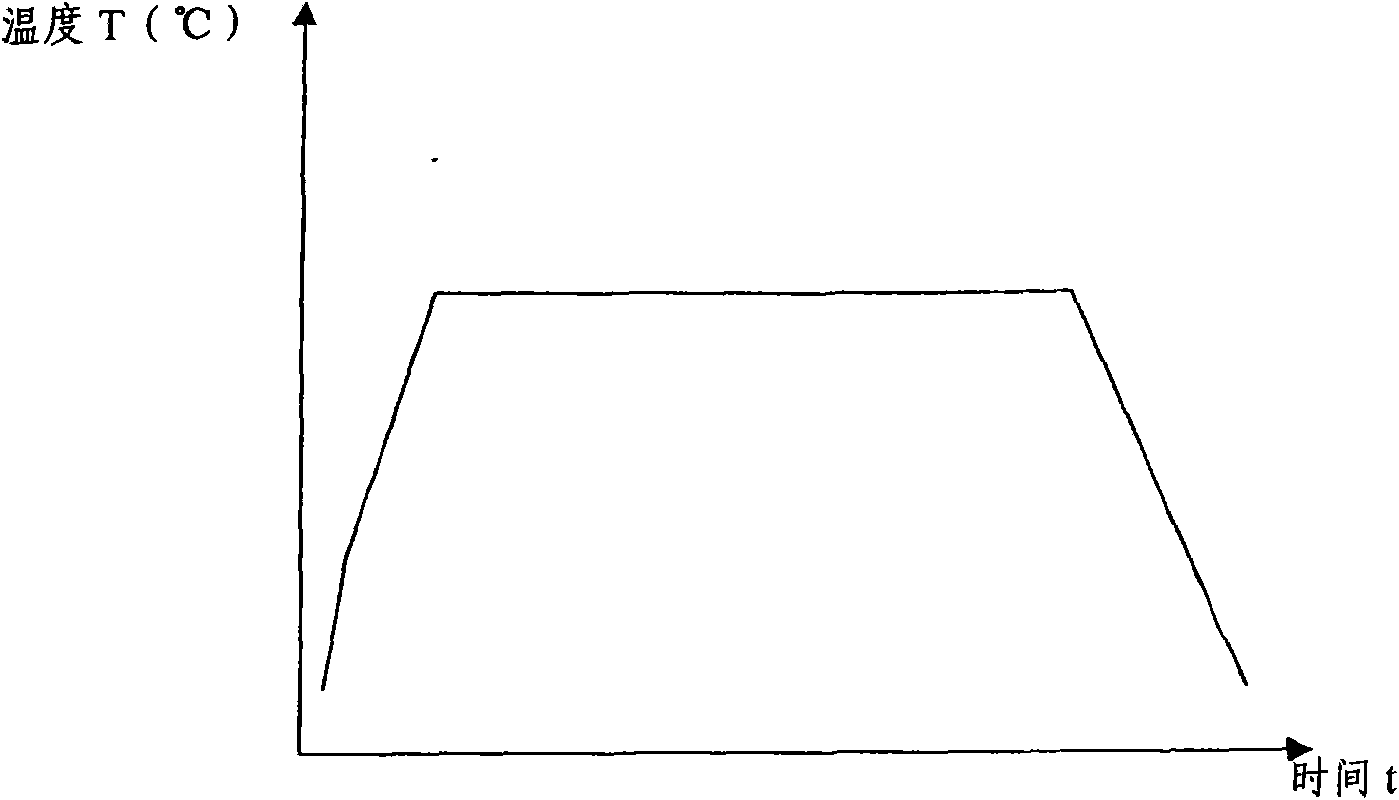

[0028] In order to make both InP and InGaAs materials obtain higher carrier concentrations and clear PN junction interfaces, the applicant accurately calculated the diffusion time of each layer of materials, and when the InP layer with a certain thickness is diffused and ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com