Dynamic determination method of hydrogen partial pressure of aluminum alloy melt

A technology for dynamic measurement of aluminum alloy melts, which is applied in the field of metallurgy and casting, can solve problems affecting test speed, etc., and achieve the effects of improving test efficiency, eliminating the need for hydrogen charging, and shortening test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

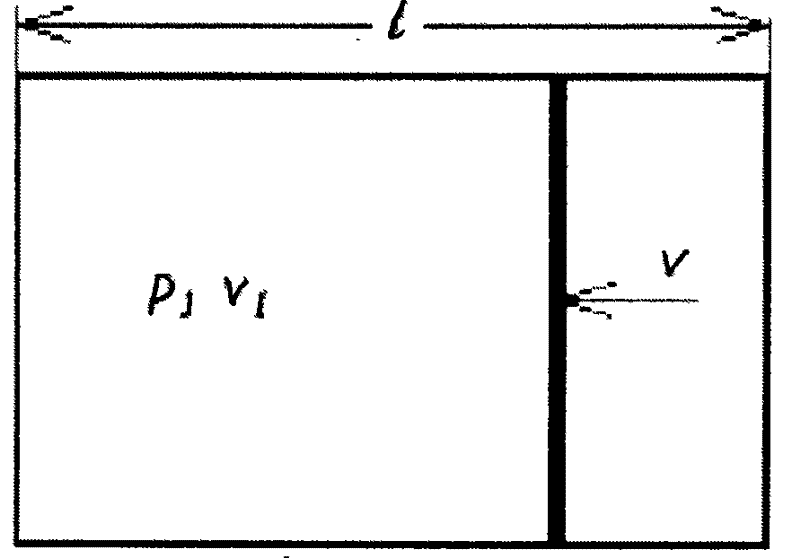

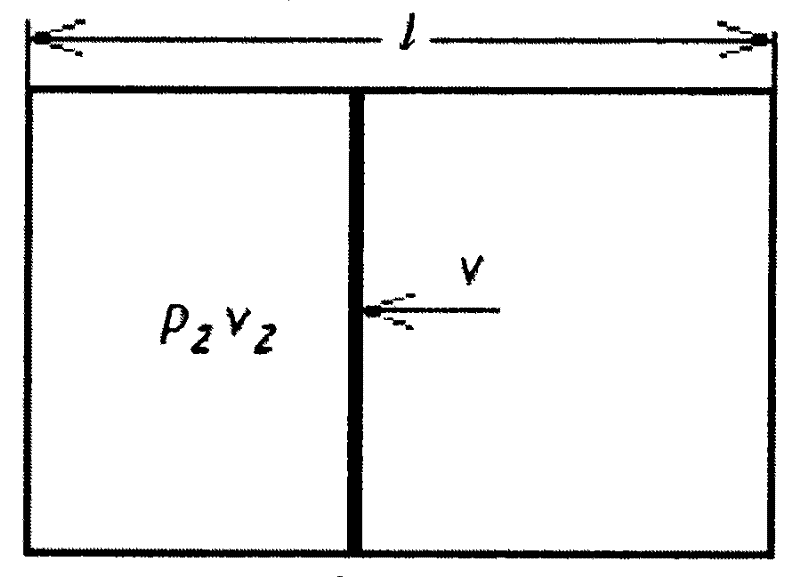

[0017] The dynamic measurement method of the hydrogen partial pressure of the aluminum alloy melt first uses the vacuum pump to make the vacuum chamber into a vacuum state, inserts the probe into the molten aluminum, opens the valve between the probe and the vacuum chamber, starts the reducer unit, and continuously reduces the vacuum of the hydrogen measurement system. The volume of the chamber is used to gradually reduce the vacuum in the system, and the hydrogen partial pressure of the melt is dynamically measured. The test condition of this method is to ensure that the vacuum system is highly airtight (that is, no air leakage), and the displacement speed of the vacuum chamber must be determined, that is, the pressure at each moment in the vacuum chamber must be calculable. As shown in accompanying drawing 1, the length of the vacuum chamber can vary between 0-1, assuming that the pressure of the vacuum chamber at a certain moment is P 1 , the volume is changed at a constant...

Embodiment 2

[0021] In the method for dynamic measurement of hydrogen partial pressure of aluminum alloy melt described in Example 1, the process of using a vacuum pump to bring the vacuum chamber into a vacuum state refers to: expanding the variable volume vacuum chamber to the maximum volume, opening the gap between the vacuum chamber and the vacuum pump. valve, close other valves, the sensor starts to work at this time, the vacuum pump evacuates the vacuum chamber, and the vacuum degree reaches 10 3 Pa level, close all valves so that the pressure in the vacuum chamber can quickly approach the hydrogen partial pressure of the melt.

[0022] In the process of increasing the pressure in the vacuum chamber, the dynamic measurement of the hydrogen partial pressure of the melt refers to the dynamic monitoring of the actual pressure value in the chamber and the real-time calculation of the theoretical pressure value and the difference between the actual pressure value and the actual pressure va...

Embodiment 3

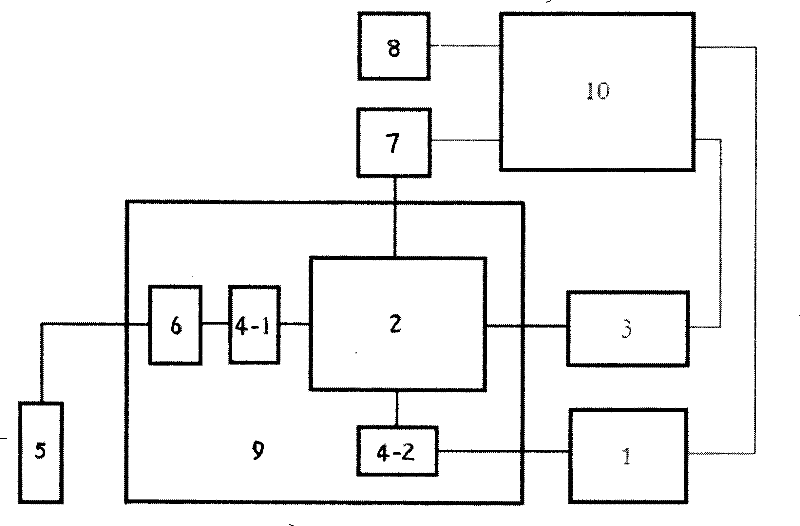

[0024] In the method for dynamic determination of the hydrogen partial pressure of aluminum alloy melt, the vacuum pump is a vacuum pump 1 that can achieve the initial vacuum degree required by the test experiment, and the vacuum pump is connected to a variable-capacity vacuum chamber 2 whose volume is changed by a deceleration unit, The vacuum chamber and the detected aluminum melt are connected by a probe 5, and the vacuum chamber is also equipped with an isolation unit 6 to prevent the aluminum alloy melt from being sucked into the vacuum chamber after the probe is damaged. It is directly connected to the pressure transmitter, and the signals output by the pressure sensor 7 and the temperature sensor 8 installed on the vacuum chamber are sent to the data acquisition and processing unit 10 .

[0025] The data acquisition and processing unit includes a signal conditioning circuit, an analog / digital conversion module, a serial communication interface and an industrial control c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com