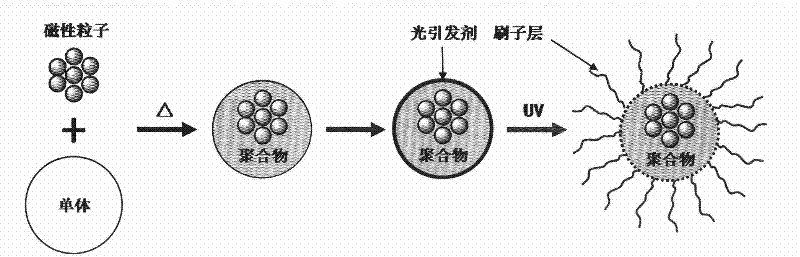

Method for preparing nanometer spherical polyelectrolyte brush with magnetic kernel

A polyelectrolyte brush and electrolyte monomer technology, which is applied in the field of targeted therapy and can solve problems such as difficult recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 Co-precipitation method prepares oil-soluble iron ferric oxide nanoparticles

[0024] 48.0g FeCl 3 ·6H 2 O and FeSO 4 ·7H 2 After O was dissolved in 100ml of deionized water, pour it into a 1000ml three-necked flask, add 300ml of deionized water, and turn on the mechanical stirring and oil bath. The temperature of the oil bath was set to 90°C, and the stirring speed was set to 300 rpm. After the oil bath is stable, add 21g of oleic acid at one time, and immediately add 120ml of ammonia water dropwise after the addition of oleic acid is completed, and the reaction solution gradually changes from red to black during the process of adding ammonia water dropwise. The co-precipitation reaction was completed after 2 hours. The black reaction solution was washed three times with deionized water and absolute ethanol under the action of strong magnetism to remove the remaining ammonia and oleic acid, and the final treatment solution was suction filtered to obtai...

Embodiment 2

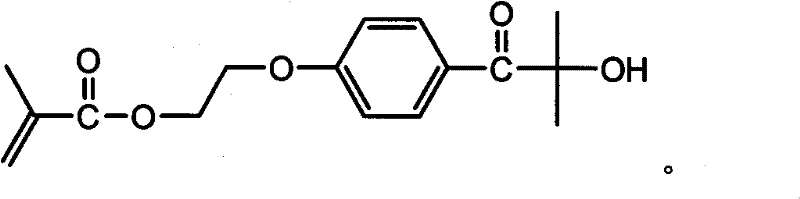

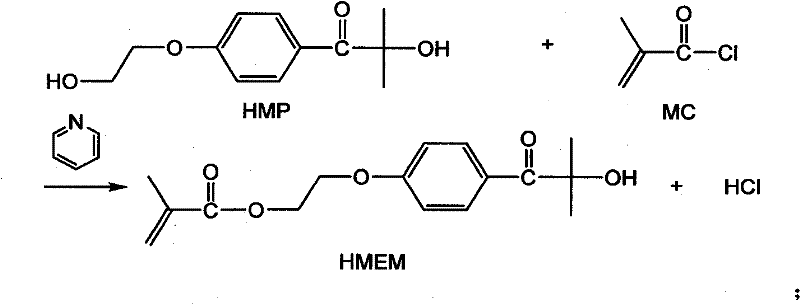

[0025] Embodiment 2 Schotten-Baumann reaction prepares photoinitiator HMEM

[0026] Pour 30.0g of photoinitiator HMP into a 500ml single-necked flask, add 150ml of acetone, stir until HMP is completely dissolved, then add 10g of newly purified pyridine, continue stirring at low temperature, and then add 13.6g of methacryloyl chloride (MC ) was dissolved in 50ml of acetone, and slowly added dropwise to the reaction flask, after the dropwise addition, it was reacted at room temperature for 12 hours to obtain an orange-yellow liquid, which was filtered to remove the beige precipitate at the bottom, and pure HMEM photoinitiated by chromatographic separation agent.

Embodiment 3

[0027] Embodiment 3 miniemulsion polymerization prepares magnetic inner core

[0028] First, dissolve 0.50g of sodium dodecylsulfonate in 200g of deionized water to form a water phase, and then prepare an oil phase by mixing 0.42g of n-hexadecane, 0.30g of azobisisobutyronitrile and 10.0g of styrene The monomers were mixed and dissolved, and then 2.0 g of ferric oxide nanoparticles obtained in Example 1 were dispersed in the oil phase to obtain a magnetic fluid, and then the magnetic fluid was poured into the water phase and ultrasonically finely emulsified for 2 hours to obtain a uniform fine particle. emulsion, the mini-emulsion was stirred and reacted at 65° C. for 20 hours, and the mini-emulsion polymerization was completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com