Micro-fluidic chip for inhibiting electroosmotic flows through grafting polyelectrolyte brush on surface of micro-channel

A polyelectrolyte brush and microfluidic chip technology, applied in the field of microfluidics, can solve the problems of demanding electric field strength, low precision, difficult operation, etc., and achieve the effects of high precision, improved control precision, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

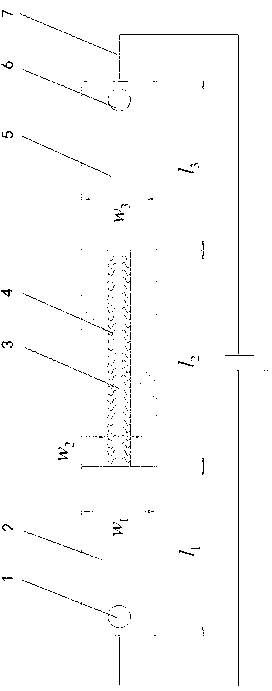

[0037] see figure 1 As shown, the present invention includes a sampling pool 1, an inlet channel 2, a slit channel 3, a polyelectrolyte brush 4, an outlet channel 5, a waste liquid pool 6, and a uniform electric field 7 parallel to the direction of the channel. Set the dimensions of each flow channel as follows: the length of the inlet flow channel 2 , the width of inlet runner 2 , the length of the slit runner 3 , the width of the slit runner 3 , the length of outlet channel 5 , the width of outlet channel 5 .

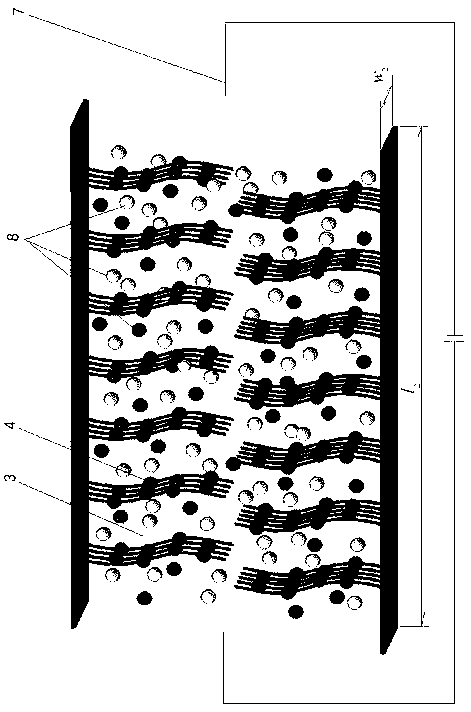

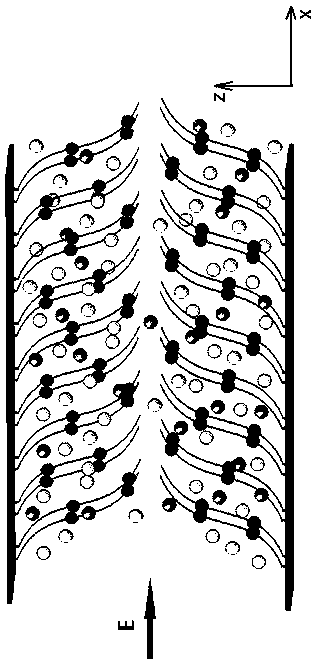

[0038] In the present invention, the surface of the slit channel 3 contains silicon crystal material. Hydroxyl-terminated polyvinyl alcohol (PVA) was prepared by active free radical method. The hydroxyl group at the terminal of the polyelectrolyte brush 4 reacts with the silanol group on the silicon wafer to form a polyelectrolyte brush. grafting density , Represents no polyelectrolyte brushing effect. And apply a uniform electric field 7 in the dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com