Method for preparing superhydrophobic surface by using nano-particles for assisting micromolding

A superhydrophobic surface and nanoparticle technology, which is used in the field of nanoparticle-assisted micromolding to prepare polymer superhydrophobic surfaces, can solve problems such as neglecting functions, and achieve broad market prospects, good controllability and repeatability, and wide application value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Nano-TiO 2 Dispersion: weigh 5g nano-TiO 2 (Zhejiang Hongsheng Material Technology Co., Ltd., HR3) was poured into 95g of absolute ethanol, and 0.15g of KH570 (Nanjing Shuguang Chemical Group Co., Ltd.) was added to adjust the pH to 3.5. Stir for 1 hour to fully hydrolyze KH570. Ultrasound for 4 hours under stirring to obtain uniformly dispersed nano-TiO 2 The slurry is adjusted to a pH value of 7 and placed for storage.

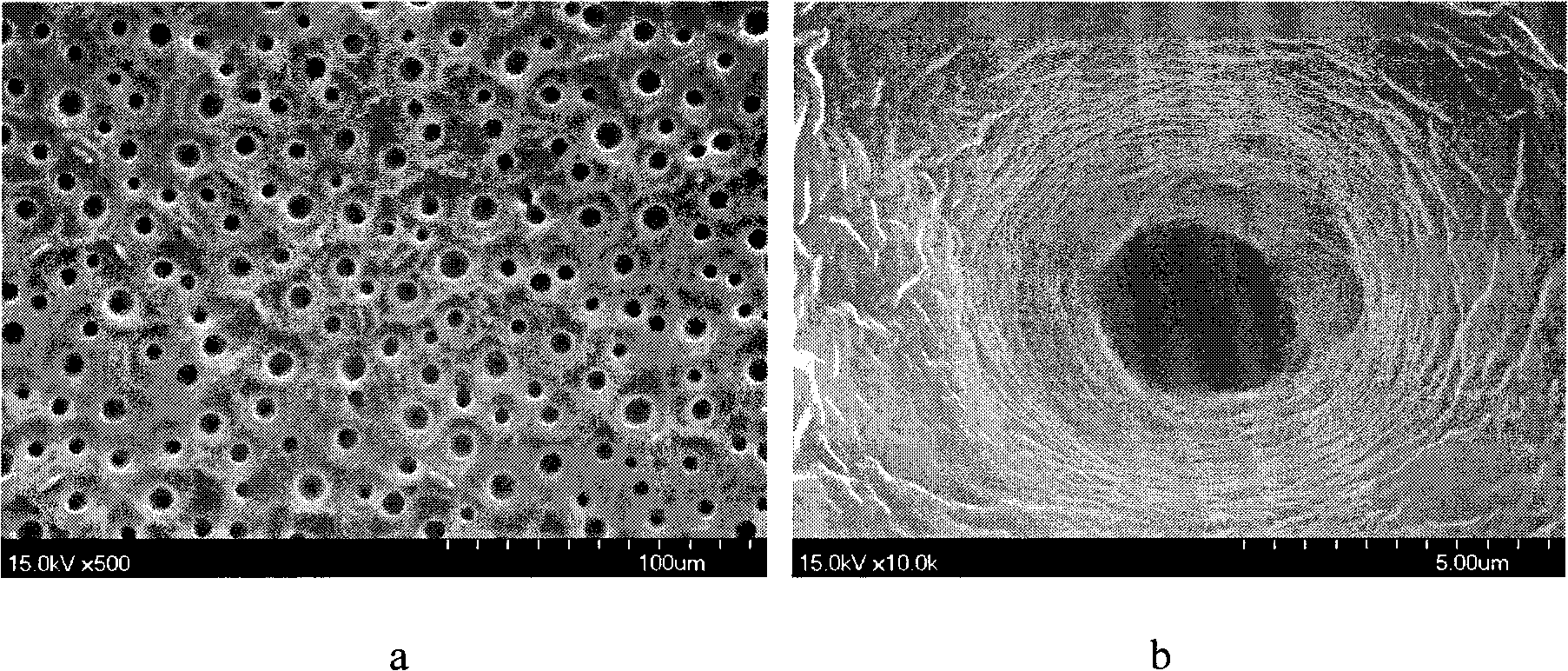

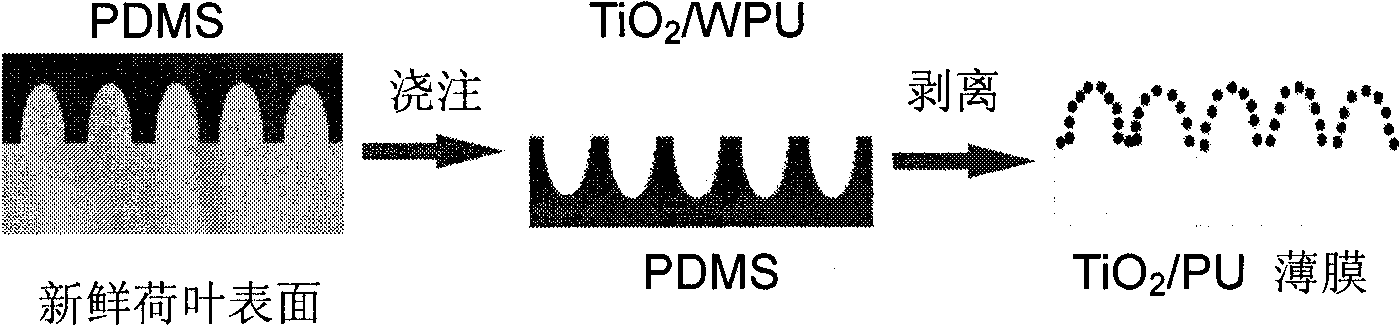

[0039] Preparation of PDMS template: Mix PDMS prepolymer (polydimethylsiloxane, Dow Corning, USA, Sylgard 184) with a mass ratio of 10:1 and its supporting cross-linking agent (Dow Corning, USA, Sylgard 184) After vacuum treatment for 30min, it was cast on the fresh lotus leaf adaxial surface (i.e. ventral surface), placed at room temperature for 24h, then transferred to a 40°C oven to react for 2h, and after curing, the PDMS was peeled off to obtain a template ( figure 1 a is the surface structure of the soft template at a small magnification, b i...

Embodiment 2

[0043] Preparation of ATO / WPU (antimony-doped tin dioxide / water-based polyurethane) thermal insulation coating: first weigh 30g of ATO powder (Shanghai Huzheng Nano Technology Co., Ltd., ATO-P100, nanoscale) and 70g of deionized water, add 0.6g KH570, using agate beads of 3 mm to 6 mm as ball milling beads, ball milling and dispersing for 72 hours at a pH value of 4.5 (adjusting the pH with oxalic acid) to obtain a stably dispersed ATO slurry, take 10 mL of the ATO slurry and mix it into 60 mL of WPU (30%) , to get ATO / WPU thermal insulation coating.

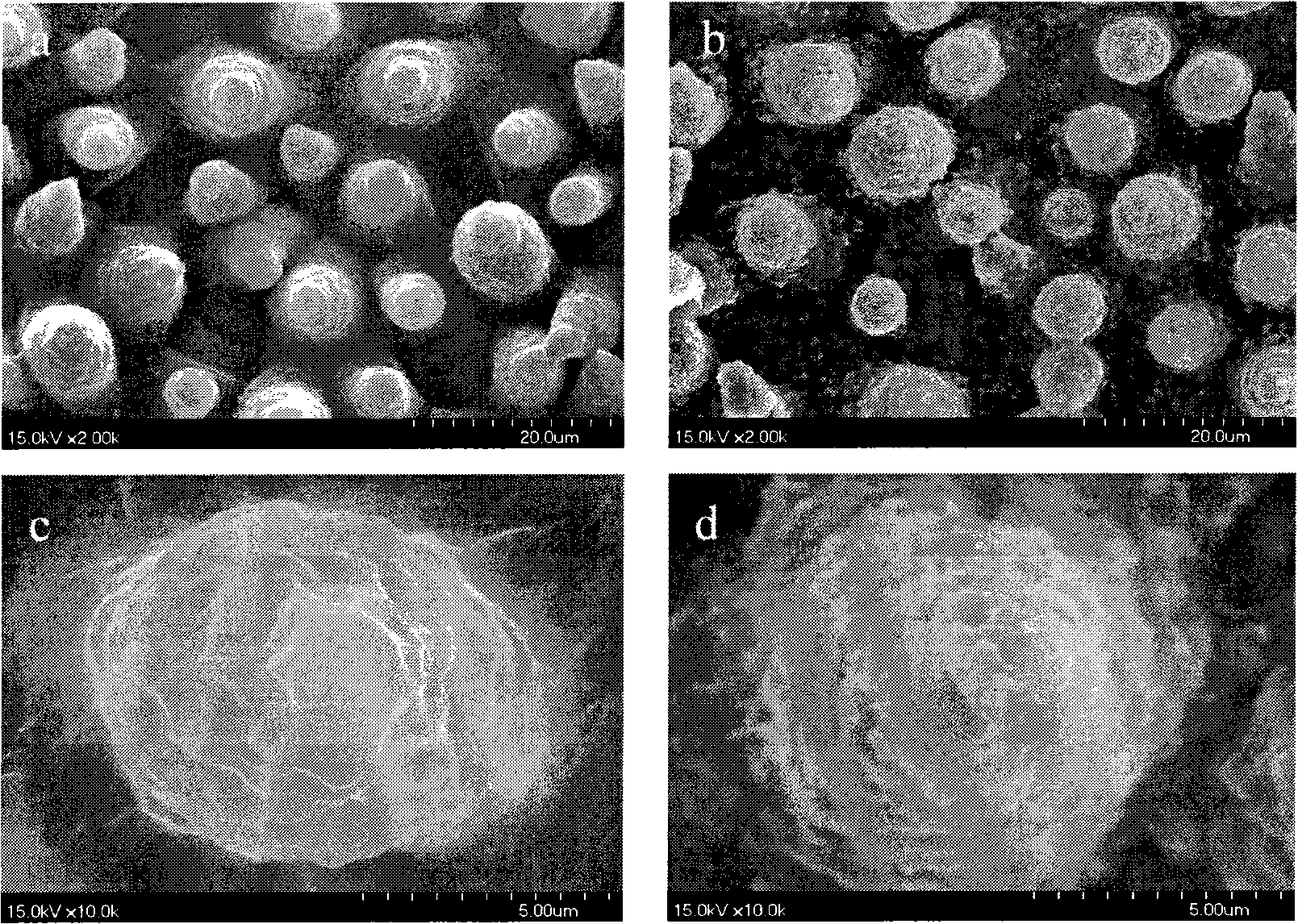

[0044] Preparation of PDMS template and ATO / WPU composite film: PDMS template is prepared with example 1, with oxygen plasma treatment (-0.1MPa under treatment 5 minutes) PDMS template has one side of dimple to make it hydrophilic, then ATO / WPU The thermal insulation coating and pure WPU coating (without ATO) were evenly poured onto two PDMS templates (3×3cm 2 ) on the hydrophilic surface, dried in an oven at 80°C, taken out an...

Embodiment 3

[0046] Nano-TiO 2 The dispersion and the preparation of the PDMS template are the same as in Example 1. Take 100 μL of nano-TiO with a solid content of 5% 2 Slurry was evenly spin-coated on 3 x 3 cm 2 On the PDMS film plate, after it is dried, LDPE (Shanghai Petrochemical, N220) is evenly covered on its surface. Heat LDPE in an oven at 200°C for 30 minutes, and then quickly clamp it with a certain pressure clamp (~500g / cm 2 ), stabilized in an oven for 15 minutes, then took it out to stand at room temperature, cooled, and peeled off to obtain the prepared sample. The sample preparation process is as Figure 9 As shown, the surface microstructure and contact angle are as Figure 10 , Figure 11 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com