Method for synthesizing 1,6-hexamethylene glycol by using dimethyl adipate gas phase and hydrogen

A technology of dimethyl adipate and hexanediol, which is applied in the field 1, can solve problems such as difficult treatment of lead-containing guard beds, and achieve the effects of improving physical properties and catalytic properties, strong penetration ability, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

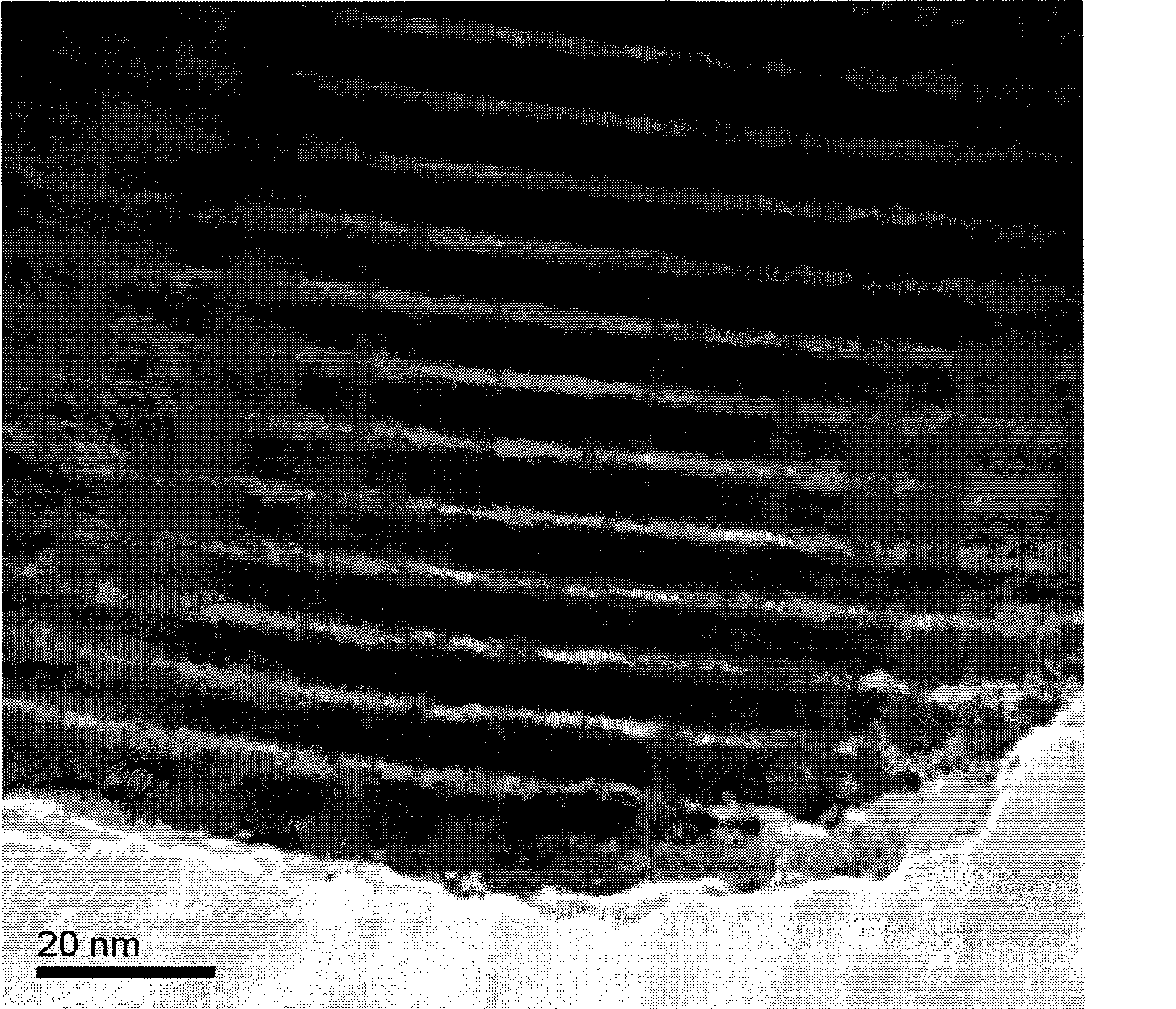

Image

Examples

Embodiment 1

[0044] 1. Preparation of guard bed

[0045] Coal-based activated carbon was first soaked with 10% hydrochloric acid solution and stirred on a stirrer for 18 hours, then kept in an oven at 100°C for 2 hours, and washed repeatedly with deionized water until neutral. Then, it was evaporated to nearly dryness under 500W intermittent power in a microwave oven, dried by microwave radiation (120° C.) for 20 minutes, and cooled and preserved for future use.

[0046] 5 g of pretreated coal-based activated carbon was impregnated in 25 mL of K 2 CO 3 and CaCO 3 In a solution of 1 mol / liter respectively, stir in a stirrer for 4 hours, then evaporate to near dryness in a microwave oven with 500W intermittent power, and cool to room temperature; 2 CO 3 and CaCO 3 Put the activated carbon into a quartz glass tube with a sieve plate, and pass nitrogen protection under the tube to prevent the activated carbon from oxidizing and burning. Place the quartz tube in a reaction furnace for calc...

Embodiment 2

[0055] 1. Preparation of guard bed

[0056] The coal-based activated carbon after the pretreatment of 5 grams of embodiment 1 is impregnated in 25 milliliters of K 2 CO 3 and CaCO 3 In a solution of 3mol / L respectively, stir in a stirrer for 4 hours, then evaporate to nearly dryness in a microwave oven with 500W intermittent power, dry for 30 minutes under microwave radiation (120°C), and cool to room temperature; 2 CO 3 and CaCO 3 The activated carbon is loaded into a quartz glass tube with a sieve plate, and the tube is protected by nitrogen to prevent the oxidative combustion of the activated carbon. The quartz tube is placed in a reaction furnace at 350°C for 4 hours. After the calcination, continue to cool to room temperature with nitrogen, and then granulate , that is, 30.7wt% activated carbon, 43.5wt% K 2 A guard bed of O and 25.8 wt% CaO.

[0057] 2. Preparation of MCM-48 carrier:

[0058] Tetraethyl orthosilicate (TEOS), cetyltrimethylammonium bromide (CTAB), s...

Embodiment 3

[0065] 1. Preparation of guard bed:

[0066] The coal-based activated carbon after the pretreatment of 5 grams of embodiment 1 is impregnated in 25 milliliters of K 2 CO 3 and CaCO 3 In the solutions of 1 mol / L and 3 mol / L respectively, stir in a stirrer for 4 hours, then evaporate to nearly dryness in a microwave oven with 500W intermittent power, dry for 30 minutes under microwave radiation (120°C), and cool to room temperature; K 2 CO 3 and CaCO 3 Put the activated carbon into a quartz glass tube with a sieve plate, and pass nitrogen protection under the tube to prevent the activated carbon from oxidizing and burning. Place the quartz tube in a reaction furnace for calcination at 350°C for 4 hours. After the calcination, continue to pass nitrogen to cool to room temperature, granulate and fill , that is, 43.2wt% activated carbon, 20.4wt% K 2 A guard bed of O and 36.4 wt% CaO.

[0067] 2. Preparation of hydrogenation catalyst

[0068] 16.0 g Cu(NO 3 ) 2 ·3H 2 O di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com