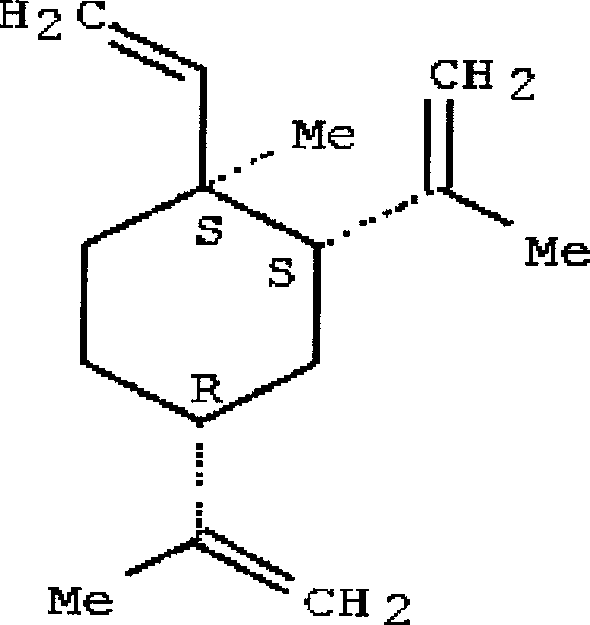

Chemical complexing directional separation and purification method for preparing high-purity beta-elemene raw material medicament

A technology for directional separation and elemene, applied in distillation purification/separation, adsorption purification/separation, hydrocarbon purification/separation, etc., can solve the problems of poor extraction stability of instruments and equipment, complicated production equipment, expensive cost, etc., and achieve production Efficiency improvement, simple equipment and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

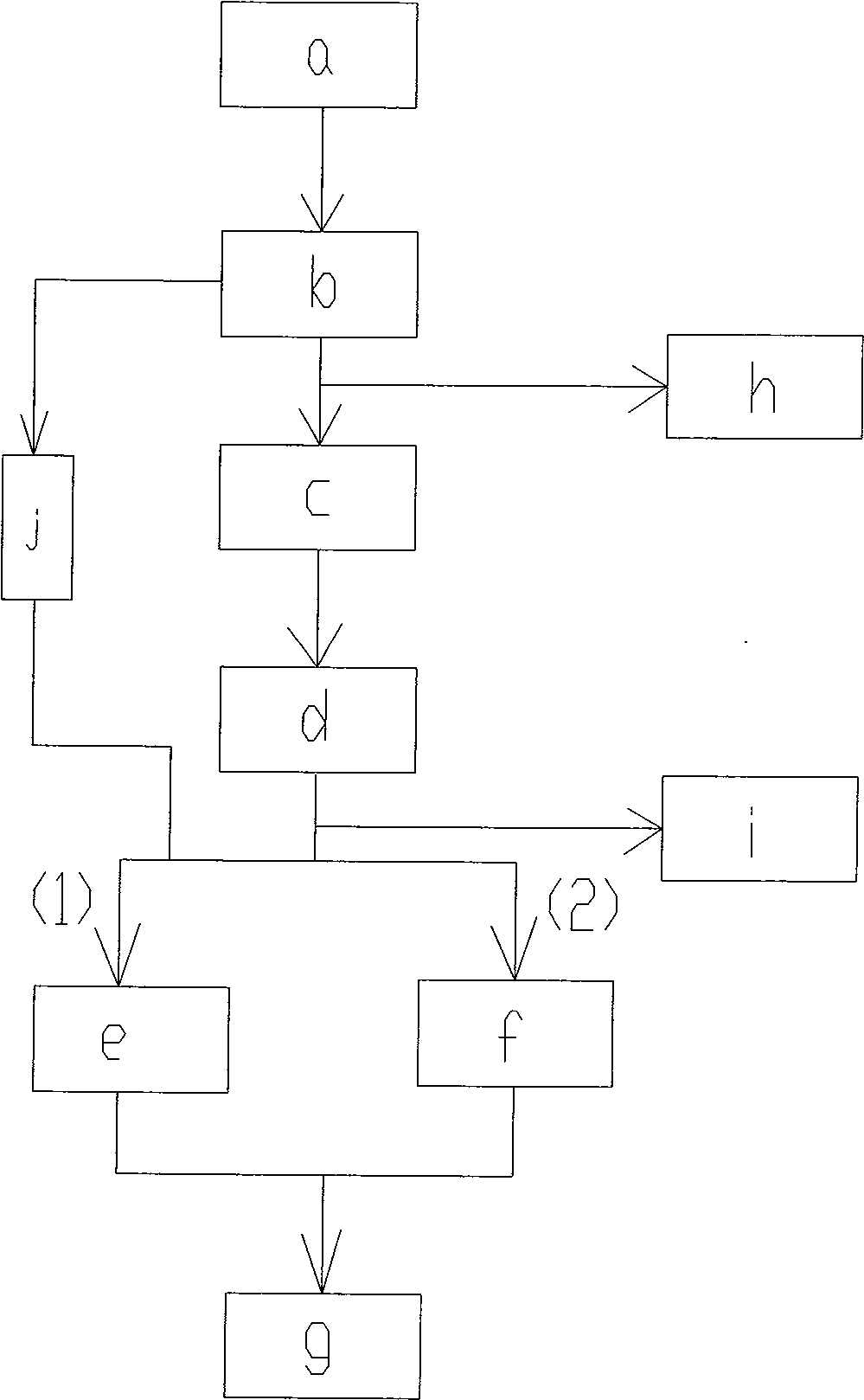

Method used

Image

Examples

Embodiment 1

[0020] a. using steam distillation to extract volatile oil from zedoary tubers, wherein the content of β-elemene is 8.1%, and the volatile oil of 100g is taken as raw material;

[0021] b. After freezing and filtering the above raw materials in a refrigerator at -4°C, mix the remaining oil phase with 100g of 100-200 mesh silica gel, use a wet method to pack the column, and put the mixed sample on a 1000g 200-300 mesh silica gel column Above, elute with petroleum ether (60-90°C), collect the fractions with low polarity, and use GC or HPLC to detect, it is found that the components with high polarity are basically removed, and the content of β-elemene is 68.2%;

[0022] c. the 68.2% β-elemene obtained in step b is extracted three times with an aqueous solution of 1.0 mol / L silver nitrate with an equal volume concentration, the liquid separation takes the lower layer of water, continues to extract three times with an equal volume of n-hexane, and the upper layer n-hexane The alka...

Embodiment 2

[0025] a. Take the fresh leaves of Lemongrass citronella as a raw material, steam distill it to obtain Java volatile oil, continue vacuum distillation to obtain β-elemene with a content of 16.5%, and take 800g as a raw material.

[0026] b. Mix the above raw materials with 1500g of 100-200 mesh silica gel, use wet method to load the column, put the mixed sample on 15000g of 200-300 mesh silica gel column, elute with cyclohexane, and collect The fractions were detected by GC or HPLC, and it was found that the components with large polarity were basically removed, and the content of β-elemene was 70.5%.

[0027] c, the 70.5% beta-elemene obtained in step b is extracted three times with an aqueous solution of 1.8mol / L silver nitrate with an equal volume concentration, and the lower layer of the aqueous phase is taken by liquid separation, and continues to be extracted three times with an equal volume of n-hexane, and the upper layer n-hexane The alkane was concentrated under redu...

Embodiment 3

[0030] a. Take the fresh leaves of Solidago sativa as raw material, extract it with carbon dioxide supercritical fluid to obtain the volatile oil of Solidago sativa, wherein the content of β-elemene is 14.3%, and after continuous distillation, β-elemene with a content of 40.6% is obtained Alkene, take 500g as raw material.

[0031]b. Mix the above raw materials with 800g of 100-200 mesh silica gel, and use the wet method to load the column. Put the mixed sample on the 8000g of 200-300 mesh silica gel column, elute with petroleum ether, and collect the samples with low polarity. GC or HPLC detection found that some components with high polarity were not removed; the components containing β-elemene were collected and passed through the silica gel column again, and the components with high polarity detected by GC or HPLC were completely removed. The content of β-elemene is 85.6%.

[0032] c, the 85.6% beta-elemene obtained in step b is extracted three times with an aqueous solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com