Alloy cast steel roll and preparation method thereof

An alloy cast steel and roll technology, applied in metal rolling, metal rolling, rolls and other directions, can solve the problems of long heat treatment cycle, low material utilization rate, complex heat treatment process, etc., achieve significant economic and social benefits, improve comprehensive Mechanical properties, the effect of reducing the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

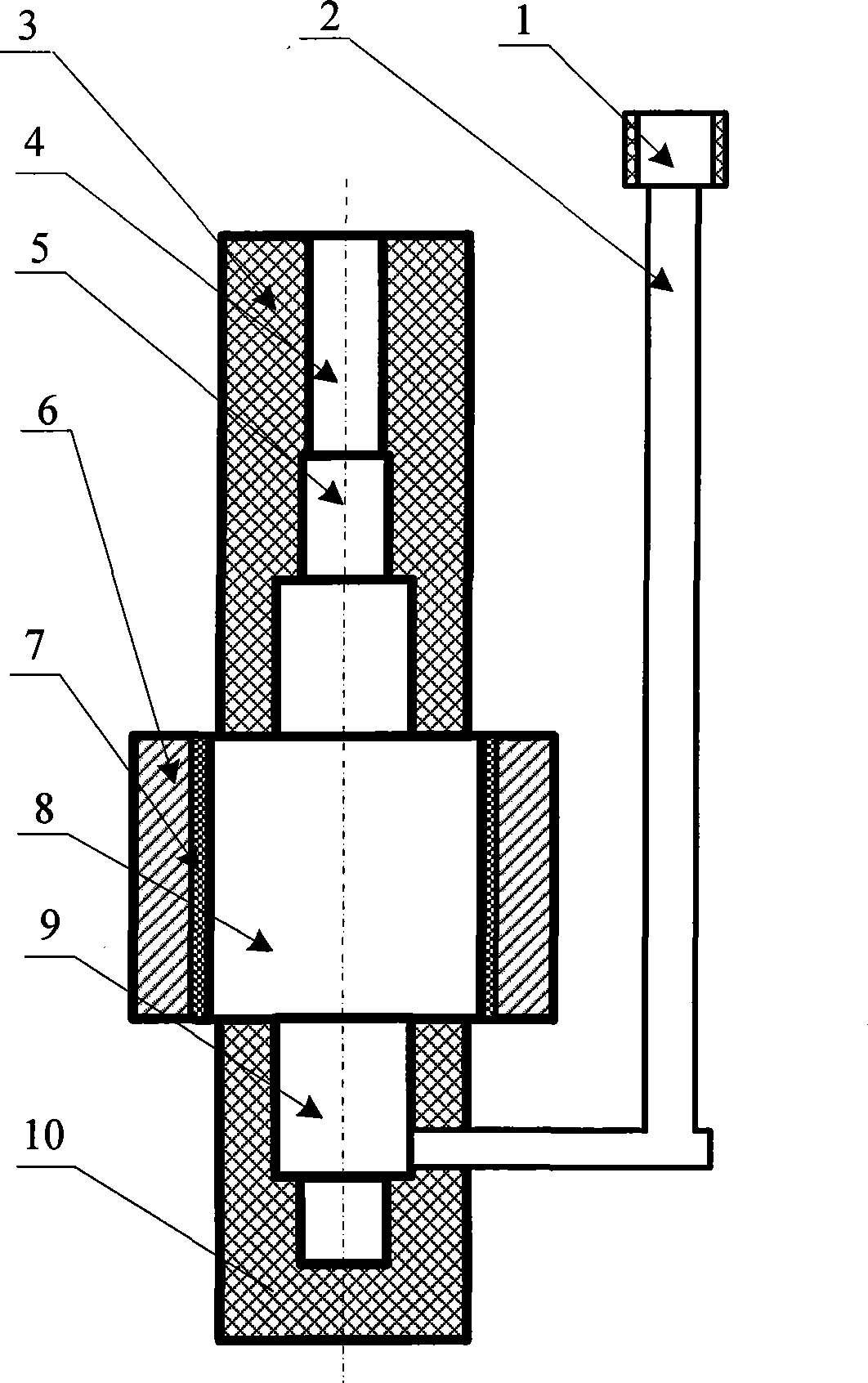

Image

Examples

Embodiment 1

[0046] The cast steel roll is smelted in a 5-ton electric arc furnace. The roll body size: φ490mm×1500mm; the roll neck: φ260mm×580mm; the total length: L=2660mm. The manufacturing process steps are:

[0047] A) Put ordinary scrap steel into an electric arc furnace and heat it to melt, add ferromolybdenum after the molten steel is melted; 8 minutes after the molten steel is melted, analyze C, Mn, Si, S, P, Mo, etc.

[0048] B) When the molten steel temperature reaches 1540℃, blow oxygen and decarburize. When the temperature reaches 1570℃, remove the slag, then add ferromanganese and ferrochromium, and add carbon powder, close the furnace door for 10 minutes and stir well, sample and analyze C, Mn, Si, S, P, Cr, Mo and other elements, adjust the composition in front of the furnace and raise the temperature to 1592℃, add Si-Ca alloy, aluminum, vanadium-nitrogen alloy, ferro-niobium and ferro-titanium in sequence, and then out of the furnace;

Embodiment 2

[0058] The cast steel roll is smelted in a 10-ton electric arc furnace. The roll body size: φ680mm×1800mm; roll neck: φ300mm×650mm; total length: L=3100mm. The manufacturing process steps are:

[0059] A) Put ordinary scrap steel into an electric arc furnace and heat it to melt, add ferromolybdenum after the molten steel is melted; analyze C, Mn, Si, S, P, Mo and other elements 10 minutes after the molten steel is melted;

[0060] B) When the molten steel temperature reaches 1548℃, blow oxygen and decarburize. When the temperature reaches 1579℃, remove the slag, then add ferromanganese and ferrochromium, and add carbon powder. Close the furnace door for 12 minutes and then fully stir, sample and analyze C, Mn, Si, S, P, Cr, Mo and other elements, adjust the composition in front of the furnace and raise the temperature to 1596℃, add Si-Ca alloy, aluminum, vanadium-nitrogen alloy, ferro-niobium and ferro-titanium in sequence, and then release the furnace;

[0061] C) Crush the lanth...

Embodiment 3

[0070] The cast steel roll is smelted in a 5-ton electric arc furnace. The roll body size: φ545mm×1500mm; the roll neck: φ300mm×530mm; the total length: L=2560mm. The manufacturing process steps are:

[0071] A) Put ordinary scrap steel into an electric arc furnace and heat it to melt, add ferromolybdenum after the molten steel is melted; analyze C, Mn, Si, S, P, Mo and other elements 4 minutes after the molten steel is melted;

[0072] B) When the temperature of molten steel reaches 1531℃, blow oxygen and decarburize. When the temperature reaches 1564℃, remove the slag, then add ferromanganese and ferrochrome, and add carbon powder, close the furnace door for 7 minutes, stir well, sample and analyze C , Mn, Si, S, P, Cr, Mo and other elements, adjust the composition in front of the furnace and raise the temperature to 1586 ℃, add Si-Ca alloy, aluminum, vanadium-nitrogen alloy, ferro-niobium and ferro-titanium in sequence, and then out of the furnace;

[0073] C) The lanthanum-cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com