Preparation method of novel protein feed additive

A protein feed and additive technology, which is applied in the preparation of hydrolyzed protein mixture and protein peptide powder feed additives, and the preparation of new protein feed additives, can solve the problem of protein degradation and anti-nutritional factors. , can not take into account the optimal reaction conditions and other issues, to achieve the effect of improving apparent digestibility, reducing piglet feed-to-meat ratio, and improving transformation utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 Hydrolyzed Protein Mixture-H1

[0050] 1) Raw material pretreatment:

[0051]The enzymolysis substrate-soybean protein isolate is pulverized to 100 mesh by a pulverizer, put into the enzymolysis tank, add water, the weight ratio of the weight of the added water to the protein contained in the enzymolysis substrate is 100:5, Stir evenly, adjust the pH to 7, soak in an enzymatic hydrolysis tank at 30°C for 1 hour, then sterilize at 80°C for 20 minutes, cool the sterilization solution to 50°C, and prepare for enzymatic hydrolysis;

[0052] 2) Enzymatic hydrolysis treatment of compound enzyme:

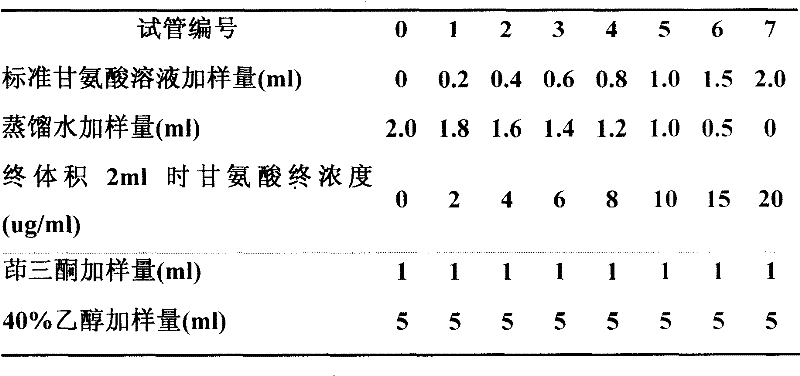

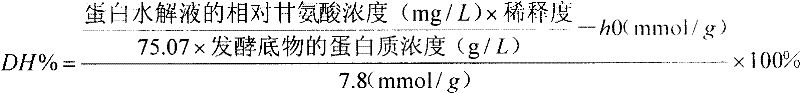

[0053] To the pretreated raw material obtained in step 1), sequentially add non-starch polysaccharide enzyme (NSP enzyme) and protease for hydrolysis. During the reaction, the temperature is 45° C., the pH is natural, and the enzymolysis is carried out for 14 hours until the degree of hydrolysis (DH%) is 20%. stop reacting when

[0054] The amount of various enzymes add...

Embodiment 2

[0075] Example 2 Hydrolyzed Protein Mixture-H2

[0076] 1) Raw material pretreatment:

[0077] Grind the enzymatic hydrolysis substrate-soybean meal to 100 mesh through a pulverizer, put it into an enzymatic hydrolysis tank, add water, the ratio of the weight of the added water to the protein contained in the enzymatic hydrolysis substrate is 100:16, and stir evenly , adjust the pH to 7, soak in the enzymatic hydrolysis tank at 37°C for 0.5 hours, then perform 10-minute sterilization at 100°C, cool the sterilizing solution to 60°C, and prepare for enzymatic hydrolysis;

[0078] 2) Enzymatic hydrolysis treatment of compound enzyme:

[0079] To the pretreated raw material obtained in step 1), sequentially add non-starch polysaccharide enzyme (NSP enzyme) and protease for hydrolysis. During the reaction, the temperature is 45° C., the pH is natural, and the enzymolysis is carried out for 24 hours until the degree of hydrolysis (DH%) is 42%. stop reacting when

[0080] The amou...

Embodiment 3

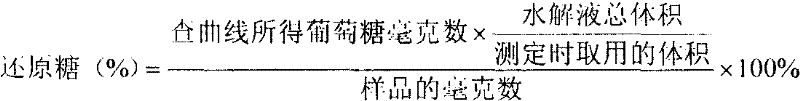

[0087] Embodiment 3 hydrolyzed protein mixture H2 reducing sugar release amount

[0088] (1) Determination of reducing sugar

[0089] ① Drawing of standard curve

[0090] Take 40Ml of acetic acid-sodium acetate buffer solution (pH5.5), add 5.0ml of DNS reagent, heat in boiling water for 5min, cool to room temperature with tap water, and dilute to 25ml with water to make a standard blank solution.

[0091] Pipette 1.00ml, 2.00ml, 3.00ml, 4.00ml, 5.00ml, 6.00ml, 7.00ml of glucose solution respectively, and dilute to 100ml with buffer respectively, and prepare glucose standard solution with concentration of 0.10mg / ml~0.70mg / ml .

[0092] Draw 2.00ml of the glucose standard solutions of the above concentration series (make two parallels), add them to the graduated test tubes respectively, then add 2ml of water and 5ml of DNS reagent respectively, oscillate electromagnetically for 3s, heat in boiling water for 5min, and then. Cool to room temperature with tap water, then dilute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com