Method for preparing fluorescent nano material converted on NaYF4

A technology of fluorescent nanomaterials and rare earth ions, applied in the field of preparation of NaYF4 up-conversion luminescent nanomaterials, can solve problems such as troublesome operation and difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 0.8041 g of Y (NO 3 ) 3 ·6H 2 O, 0.3504 g Yb (NO 3 ) 3 ·6H 2 O and 0.0692 g Er(NO 3 ) 3 ·6H 2 O (Y / Yb / Er molar ratio 70:25:5) was dissolved in 10ml of deionized water, the concentration of the mixed solution was 0.3mol / l, and then 1.2 grams of sodium polyacrylate (molecular weight was 5100) was added to make it in the mixed solution The percentage concentration is 10%, stir to make it fully dissolved. Adjust the pH value to 4 with dilute nitric acid, and keep stirring for 1h to generate a stable white complex. Then add 0.4445 grams of ammonium fluoride (the ratio of fluoride ion to rare earth ion is the stoichiometric ratio of the structural formula), and stir until the solution forms a nearly transparent colloid. It was then transferred to a 20 ml autoclave lined with polytetrafluoroethylene, and the autoclave was placed in an oven at 180° C. for 4 h. After natural cooling, centrifuge, wash, and vacuum-dry at 30°C to obtain spherical nanocrystalline gra...

Embodiment 2

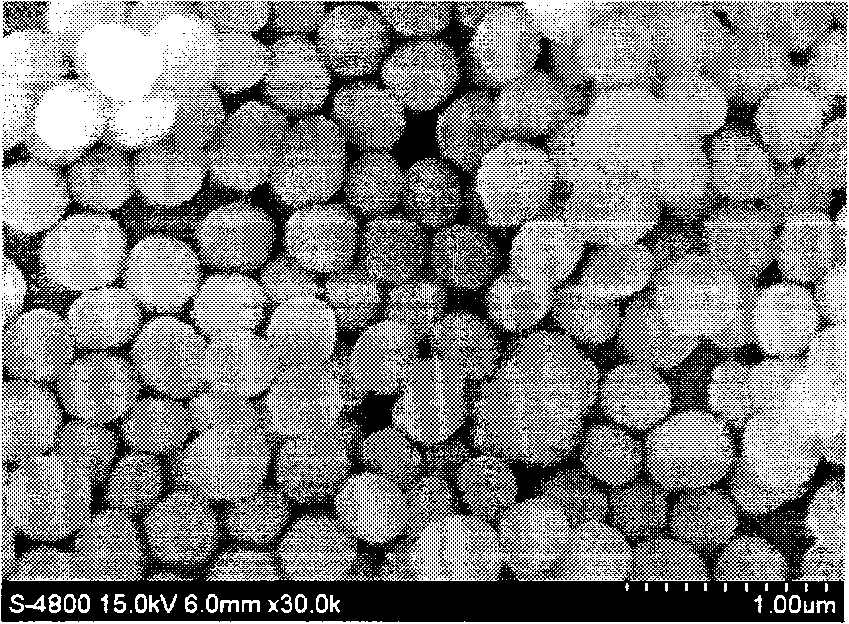

[0025] Weigh 1.0913 grams of Y (NO 3 ) 3 ·6H 2 O, 0.0140 g Yb (NO 3 ) 3 ·6H 2 O and 0.0552 g Er(NO 3 ) 3 ·6H 2 O (Y / Yb / Er molar ratio 95: 1: 4) is dissolved in 10ml deionized water, and the concentration of the mixed solution is 0.3mol / l, then adding 5ml concentration is 5% maleic acid acrylic acid copolymer sodium salt (molecular weight is 50000, the percentage concentration is 1.5%), adjust the pH value to 3.5 with 0.5mol / l dilute nitric acid, stir to make it react fully, and keep stirring for 1h. Then add 25ml of sodium fluoride solution with a concentration of 0.96mol / l, stir for 4 hours, transfer to a 60ml autoclave, and place in an oven at 140°C for 48 hours. After natural cooling, centrifuge, wash, and vacuum-dry at 80°C to obtain spherical particle-like Yb with an average size of 400nm 3+ , Er 3+ Doped with NaYF 4 Upconverting fluorescent nanomaterials. see figure 2 Field emission scanning microscope topography photographs are shown.

Embodiment 3

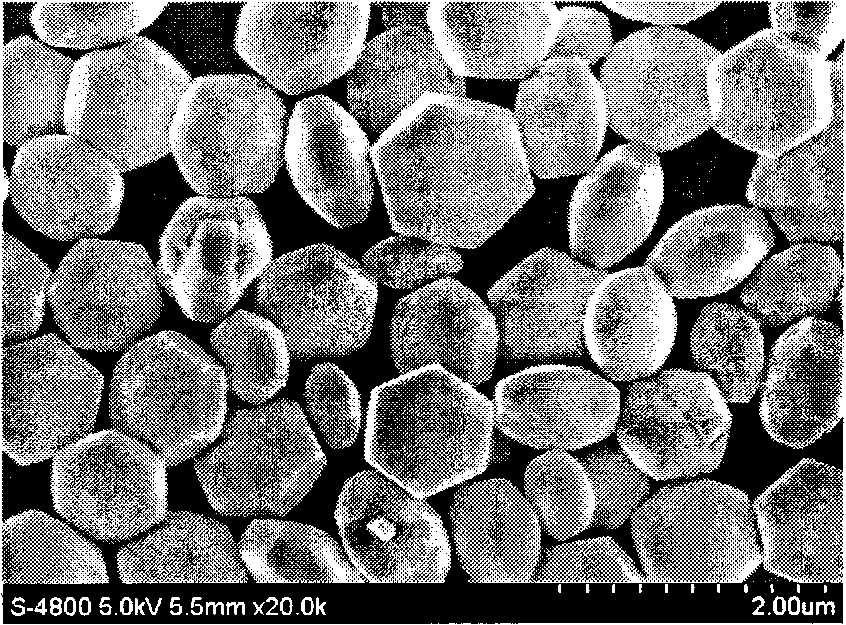

[0027] Weigh 0.2427 g of YCl 3 ·6H 2 O, 0.0388 g YbCl 3 ·6H 2 O and 0.0383 g TmCl 3 ·6H 2 O (Y / Yb / Tm molar ratio 80: 10: 10) is dissolved in 10ml deionized water, and the concentration of the mixed solution is 0.1mol / l, then adding 10ml concentration is 3% maleic acid acrylic acid copolymer sodium salt (molecular weight is 50000, the percentage concentration is 1.5%), stir to make it fully react. Adjust the pH value to 6 with dilute hydrochloric acid, and keep stirring for 1h. Then add 20ml of ammonium fluoride solution with a concentration of 0.6mol / l, stir until almost transparent, then transfer to a 60ml autoclave, and place in an oven at 180°C for 24h. After natural cooling, centrifuge, wash, and dry at 60°C to obtain hexagonal flaky crystal Yb with a size of 1 μm 3+ , Tm 3+ Doped with NaYF 4 Upconverting fluorescent nanomaterials. see image 3 Field emission scanning microscope topography photographs are shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com